Pneumatic discharging ball valve

A material ball, pneumatic technology, applied in valve details, valve devices, engine components, etc., can solve the problems of heavy weight, inability to close tightly, and inability to seal the pneumatic film discharge valve, achieving light weight, good cleaning effect, and sealing. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further set forth the present invention:

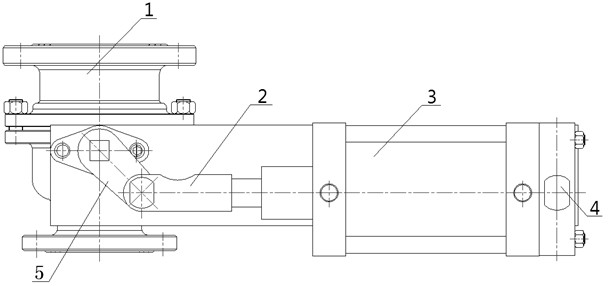

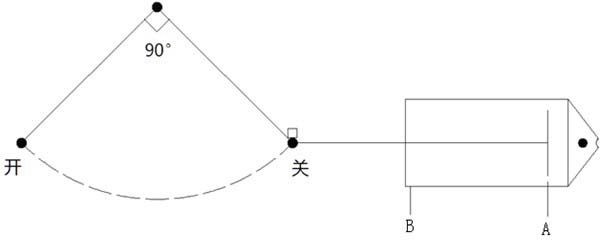

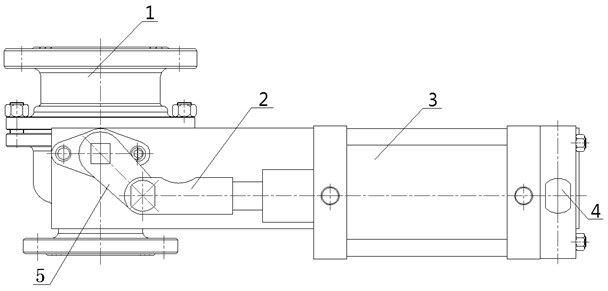

[0023] A pneumatic discharging ball valve, comprising a discharging ball valve 1, the valve stem of the discharging ball valve 1 is connected with a connecting rod mechanism, and the other end of the connecting rod mechanism is connected with a straight-stroke cylinder 3; the straight-stroke cylinder 3 drives the connecting rod mechanism Operation and then control the opening or closing of the discharge ball valve 1, the linkage mechanism includes a first connecting rod 5 and a second connecting rod 2, the first connecting rod 5 is connected to the valve stem of the discharging ball valve 1, and one end of the second connecting rod 2 is connected to the The other end of the first connecting rod 5 is movably connected, and the other end of the second connecting rod 2 is connected with the linear cylinder 3 . This straight-stroke cylinder 3 uses a solenoid valve to control its operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com