Electromagnetic pilot valve driver

An electromagnetic pilot valve and driver technology, applied in valve details, valve devices, engine components, etc., can solve the problems of simple function and inconvenient use, and achieve the effect of safe work, reliable performance and high level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

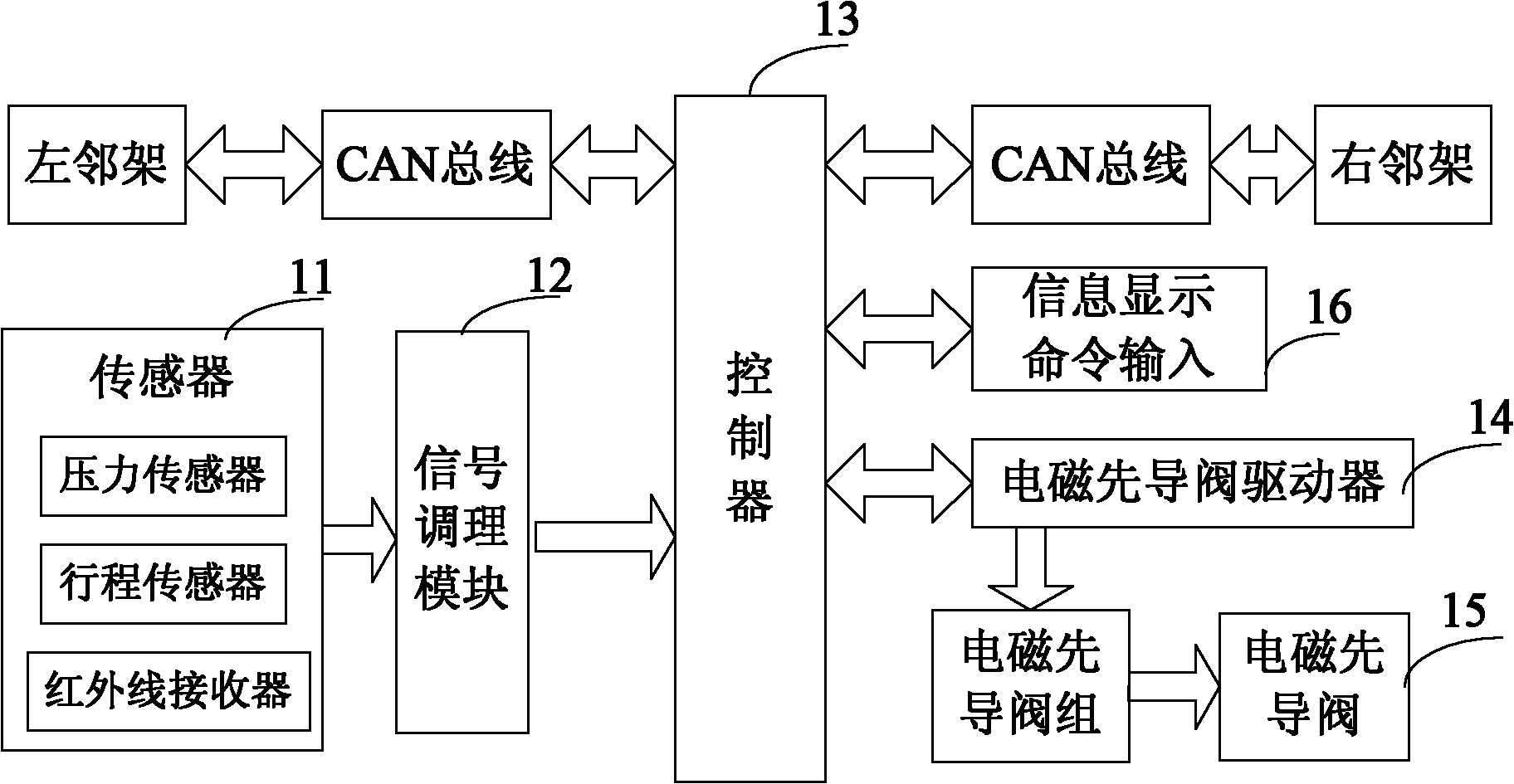

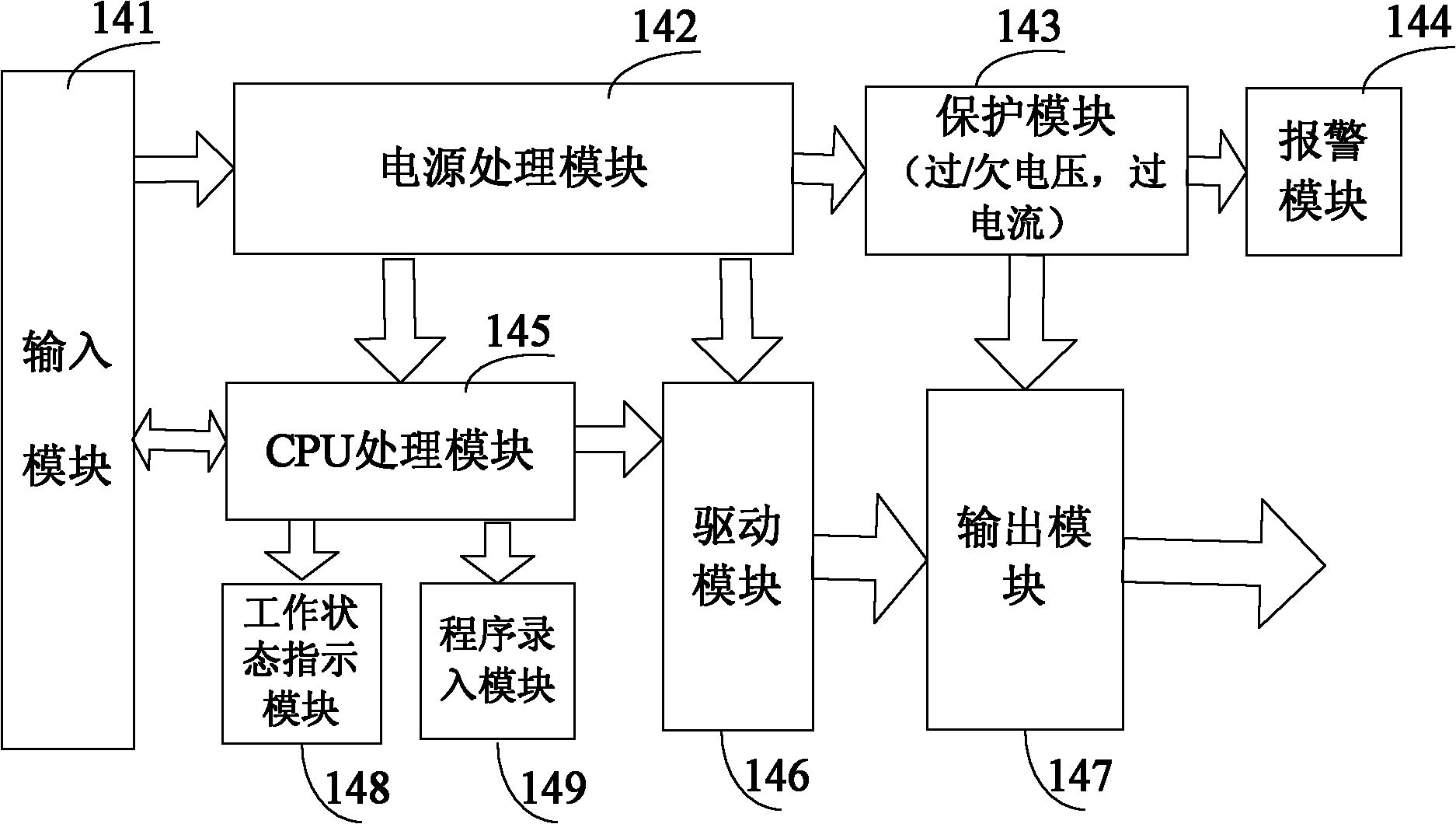

[0039] Such as figure 2 Shows the functional schematic block diagram of the electromagnetic pilot valve driver 14 used in the electro-hydraulic control system of the present invention, including: an input module 141, a power processing module 142, a protection module 143, an alarm module 144, a CPU processing module 145, a driving module 146, an output Module 147, working status display module 148, program entry module 149.

[0040] Wherein, the input module 141 is used for receiving the power signal and the control signal sent from the controller 13 of the hydraulic support.

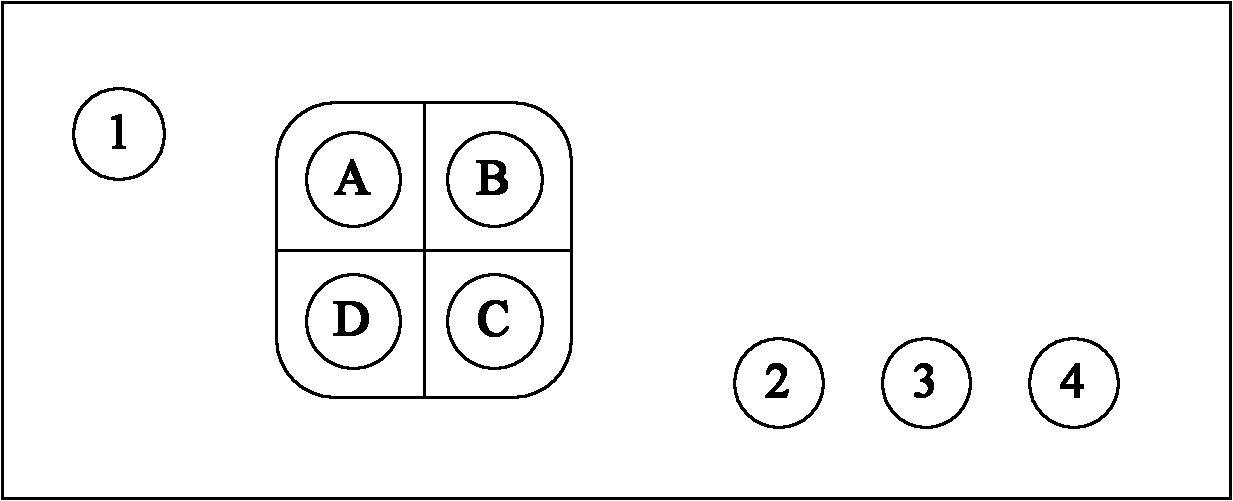

[0041] In a specific implementation, the input module 141 can be a four-port interface, and the four ports are used to connect a four-core cable connected from the controller 13 of the hydraulic support, two of which are used to transmit power signals, and the other Two cores are used to transmit control signals. Such as image 3 An interface panel including the four-port interface is shown, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com