Method for measuring minimum gas flow

A technology of gas flow and measurement method, which is applied in the direction of detecting fluid flow by measuring pressure difference and volume/mass flow generated by mechanical effects, so as to avoid the effect of measurement uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

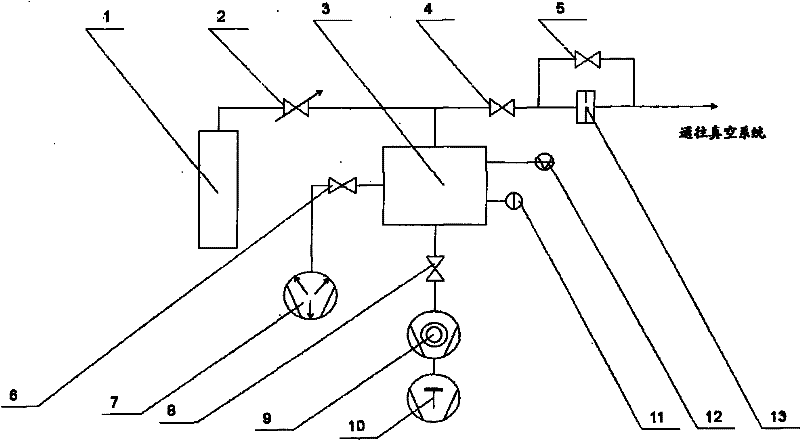

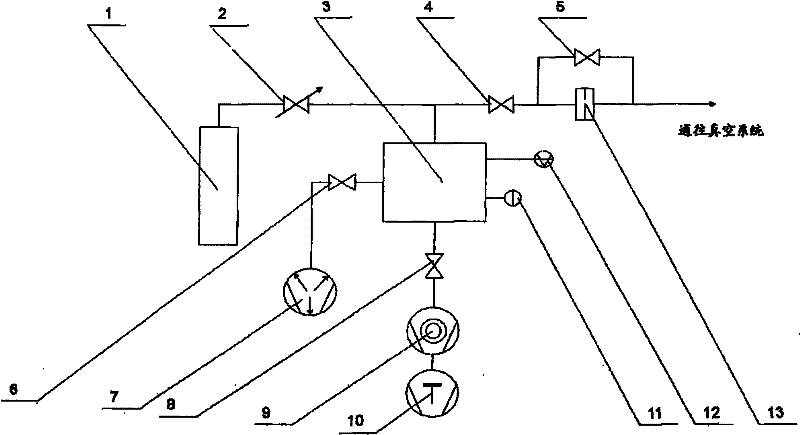

[0022] figure 1 Shown is a preferred embodiment of the present invention, comprising gas cylinder 1, fine-tuning valve 2, plenum chamber 3, valve one 4, valve two 5, connecting valve 6, getter pump 7, valve four 8, molecular pump 9 , a backing pump 10, a capacitor film gauge 11, a magnetic levitation rotor gauge 12, and a small hole 13. The gas cylinder 1 is connected to the pressure-stabilizing chamber 3 through the fine-tuning valve 2, and the small hole 13 is connected in parallel with the valve 2 5, and one end passes through the valve 1 4 and The plenum chamber 3 is connected, one end is connected with the vacuum system, the getter pump 7 is connected with the plenum chamber 3 through the connecting valve 6, the backing pump 10 and the molecular pump 9 are connected in series and then connected with the plenum chamber 3 through the valve 48, The capacitive film gauge 11 and the magnetic levitation rotor gauge 12 are directly connected to the wall of the plenum chamber 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com