Method for Determination of Pyrogallic Acid Content by High Performance Liquid Chromatography-Internal Standard Method

A pyrogallic acid and high performance liquid chromatography technology, which is applied in measurement devices, instruments, scientific instruments and other directions, can solve the problems of low accuracy and large uncertainty of test results, and achieves scientific methods, easy acquisition and preservation, Avoid the effects of instrument instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. With the instruments and reagents adopted in the technical content of the present invention.

[0048] 2. adopt the high performance liquid chromatography mobile phase operation condition that adopts in the technical content of the present invention.

[0049] 3. Prepare standard solution.

[0050] The present invention uses ellagic acid as an internal standard to measure the content of pyrogallic acid.

[0051] 3.1 Preparation of internal standard solution: Weigh 0.1g (accurate to 0.0002g) of ellagic acid in a 250mL volumetric flask, dissolve it with methanol and dilute to the mark, ultrasonicate for 10min to fully dissolve it before use.

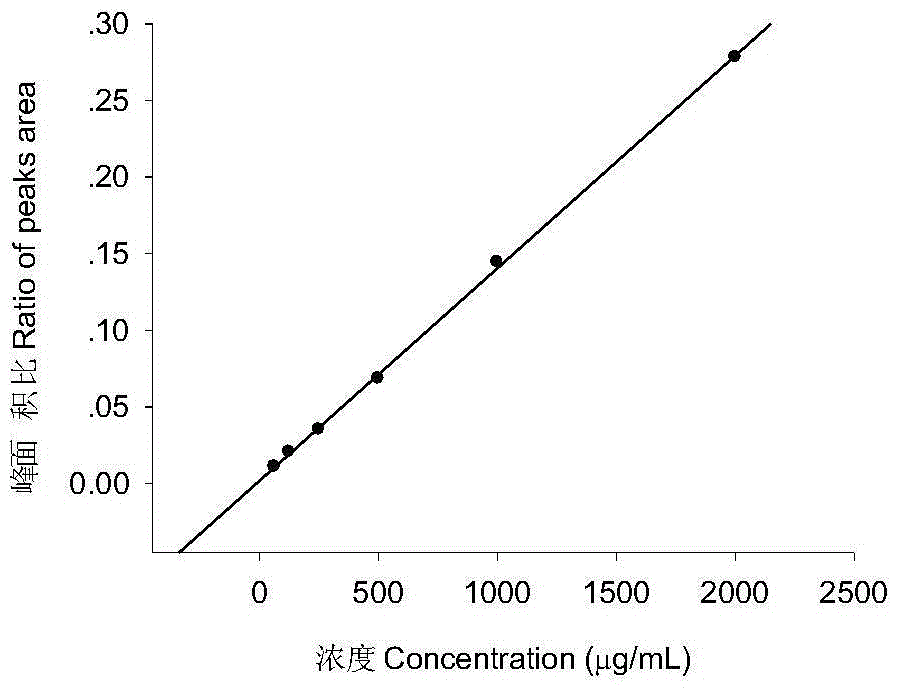

[0052] 3.2 Standard solution of pyrogallic acid: 2.0mg / mL. Accurately weigh 0.200g (accurate to 0.0002g) of pyrogallic acid into a 100mL volumetric flask, dilute to the mark with internal standard solution, shake well, and make it fully dissolved before use.

[0053] 4. Determination of pyrogallic acid content

[0054] 4.1 Making...

Embodiment 2

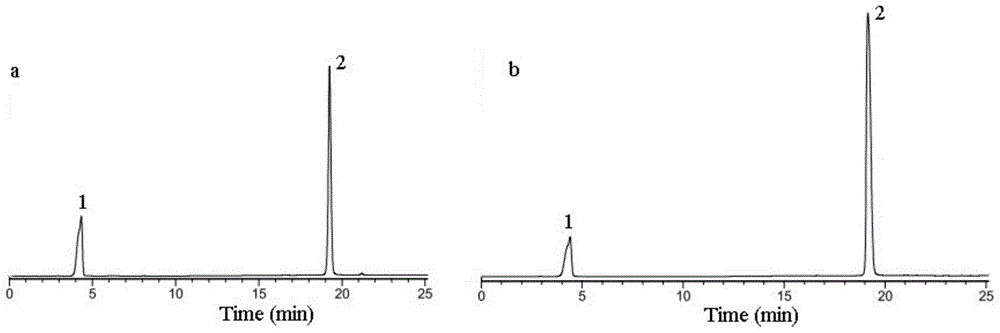

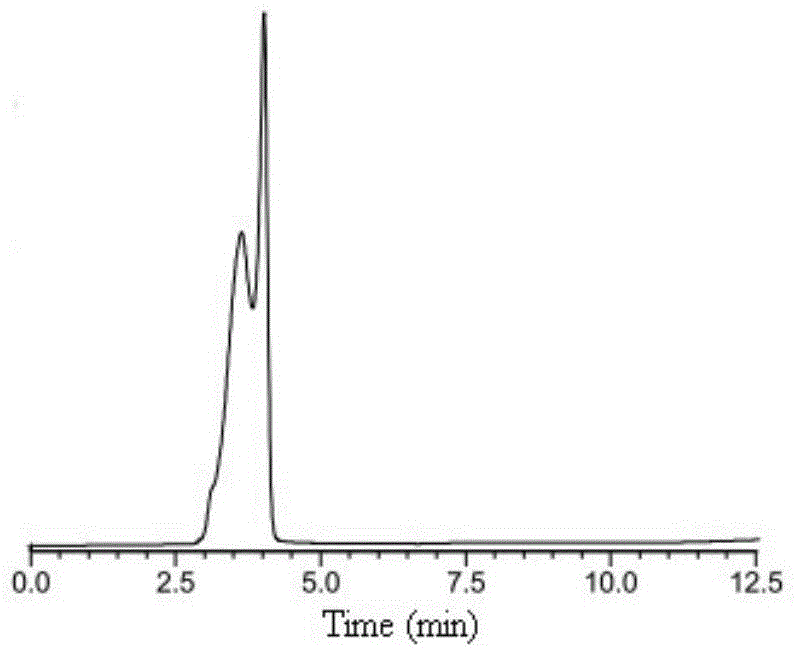

[0059] According to the analysis method and test procedure described in Example 1, 3,4,5-trimethoxybenzoic acid was used instead of ellagic acid as an internal standard to determine the content of pyrogallic acid. Obtained pyrogallic acid HPLC with 3,4,5-trimethoxybenzoic acid as internal standard ( image 3 ). It can be seen from the chromatogram that choosing 3,4,5-trimethoxybenzoic acid as the internal standard cannot achieve a good separation of the analyte pyrogallic acid and the internal standard. Therefore, 3,4,5-trimethoxybenzoic acid cannot be selected as the internal standard substance according to the analysis method and test procedure described in the method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com