A standardized automatic casting coating production device

A technology for production devices and coatings, applied in chemical instruments and methods, dissolution, mixers, etc., can solve problems such as difficulty in large-scale production, and achieve the effects of avoiding measurement uncertainty, solving pollution, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

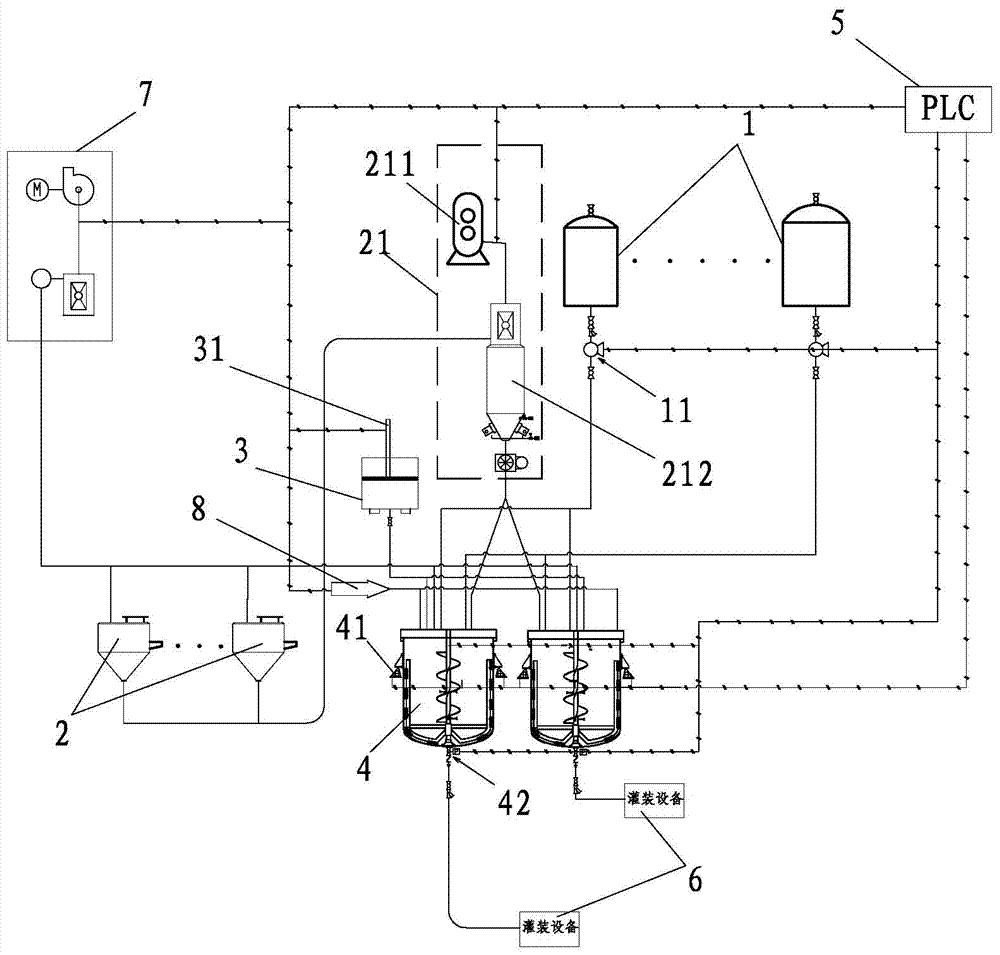

[0026] figure 1 A standardized automatic casting coating production device is shown, including several raw material storage tanks, several stirring tanks 4 and filling equipment 6, and the raw material storage tanks include several liquid material storage tanks 1, several powder material storage tanks 2 and several The colloidal slurry storage tank 3, the stirred tank is a stirred tank 4 with a kettle body weighing module 41, and the kettle body weighing module 41 is connected to the PLC5 through a signal line;

[0027] The liquid material storage tank 1, the powder material storage tank 2 and the colloidal slurry storage tank 3 are respectively communicated with the stirring tank 4 through pipelines, and are arranged on the pipeline from the liquid material storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com