Remote controllable loading method and equipment with fluid CT (Computed Tomography) scanning

A CT scanning and remote technology, applied in the field of experimental mechanics, can solve the problems of extremely high requirements for test pieces, low penetrating power of transmission electron microscope, and inability to obtain the internal structure of the measured target, and achieves convenient installation, reliable performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

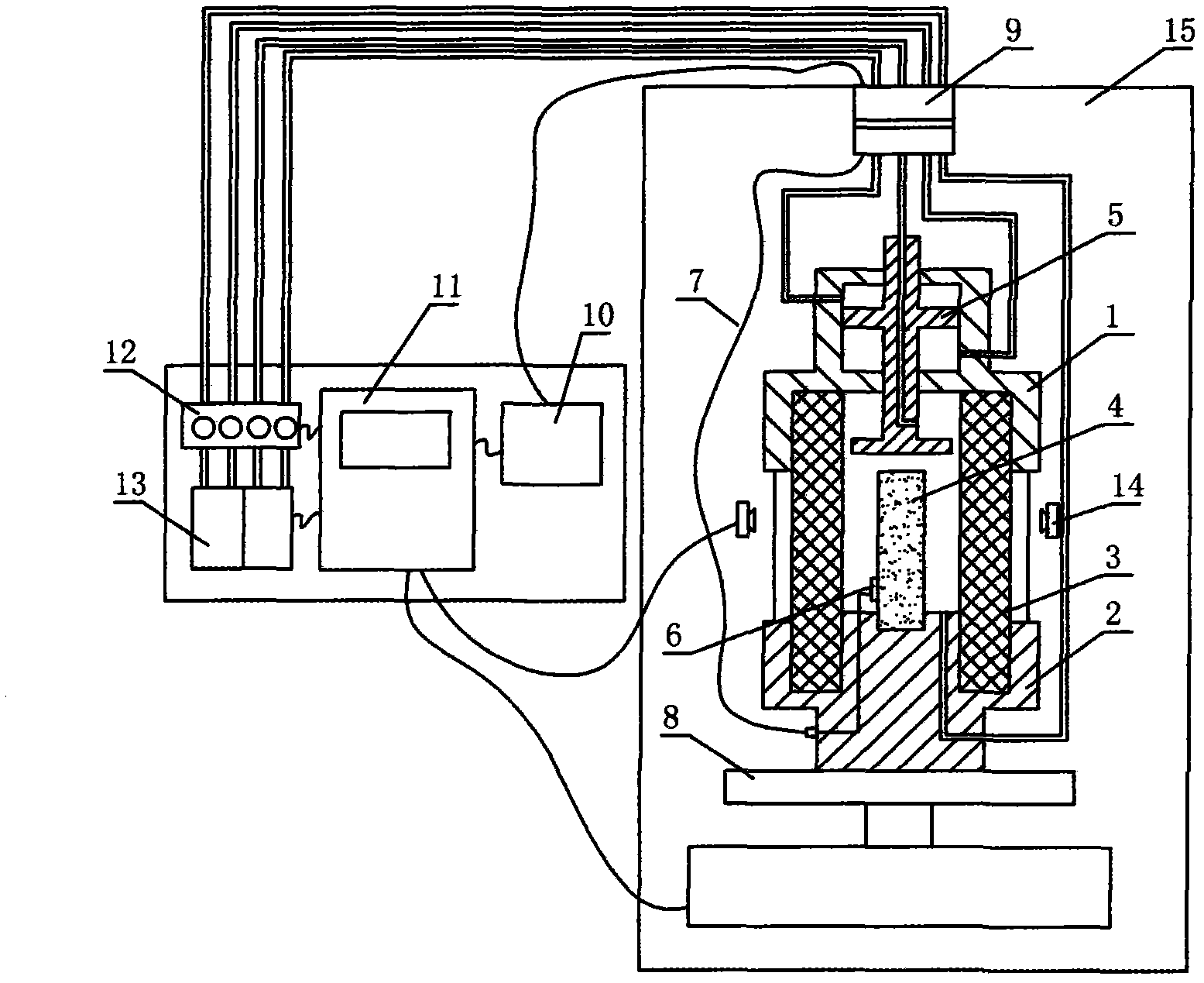

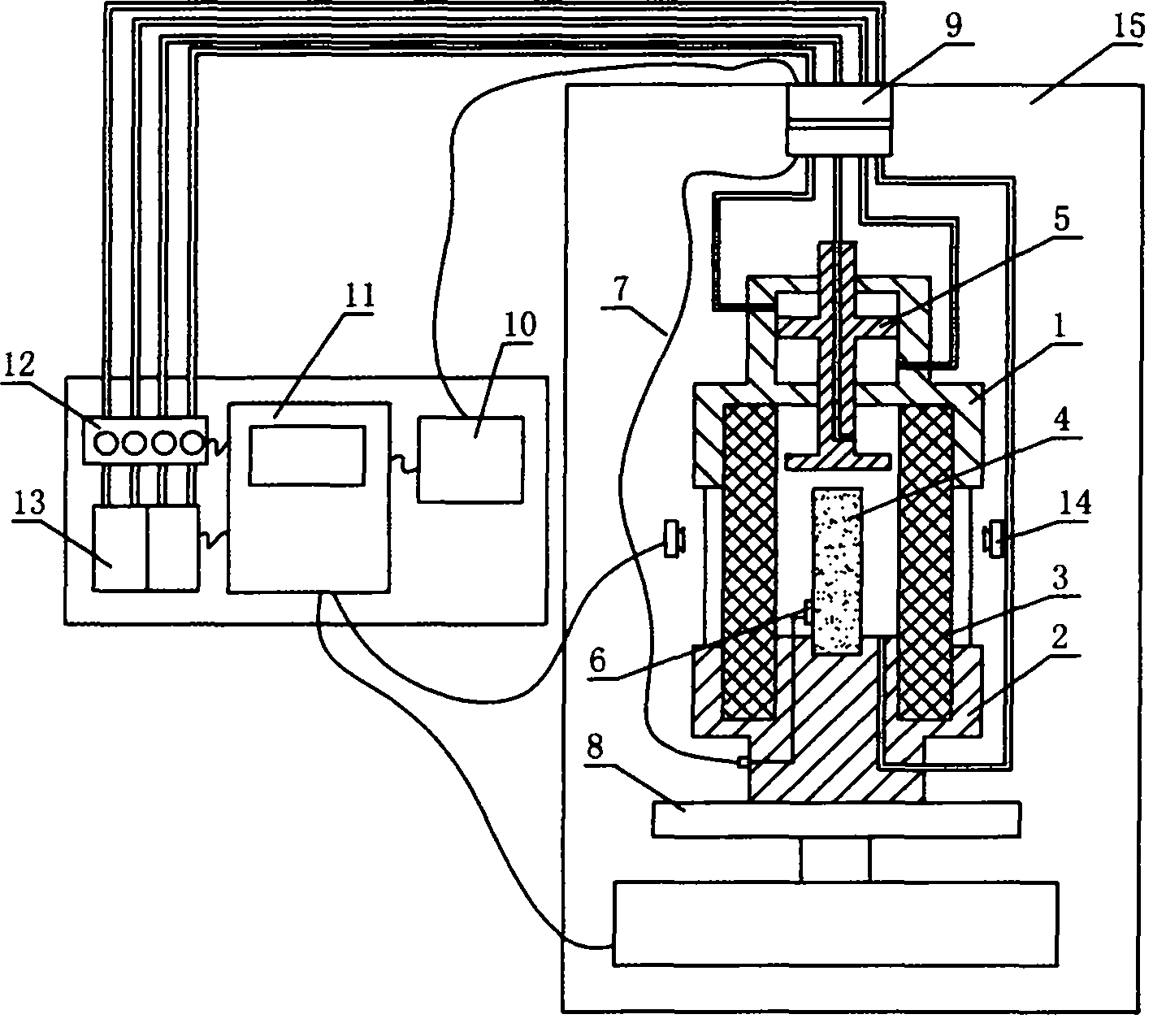

[0022] The central idea of the present invention is to install the loading mechanism and various sensors on the CT scanning rotating platform in the CT scanning shielding room, and use the manual and automatic pressure control device outside the CT shielding room to perform remote axial and / or surrounding loading on the indoor loading mechanism. To realize the dynamic process of uniaxial loading and / or pseudo-triaxial loading, and complete the CT real-time scanning of the dynamic loading process of the rock mass sample in the unmanned state of the CT shielding room, in order to accurately judge the stress change of the rock mass sample provides a basis for the structural impact.

[0023] A remote controllable loading method for fluid-containing CT scanning according to the present invention, specifically comprising:

[0024] First of all, according to the specifications of the loading mechanism, select a rock mass sample of an appropriate size. Before putting the rock mass s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com