Monitoring method and system used for in-situ real-time characterization of solar cell internal interface

A solar cell and characterization technology, applied in the monitoring of photovoltaic systems, photovoltaic power generation, electrical components, etc., can solve the problems of non-occurrence and few photovoltaic devices, achieve strong Raman activity, strong light transmission, and ensure repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

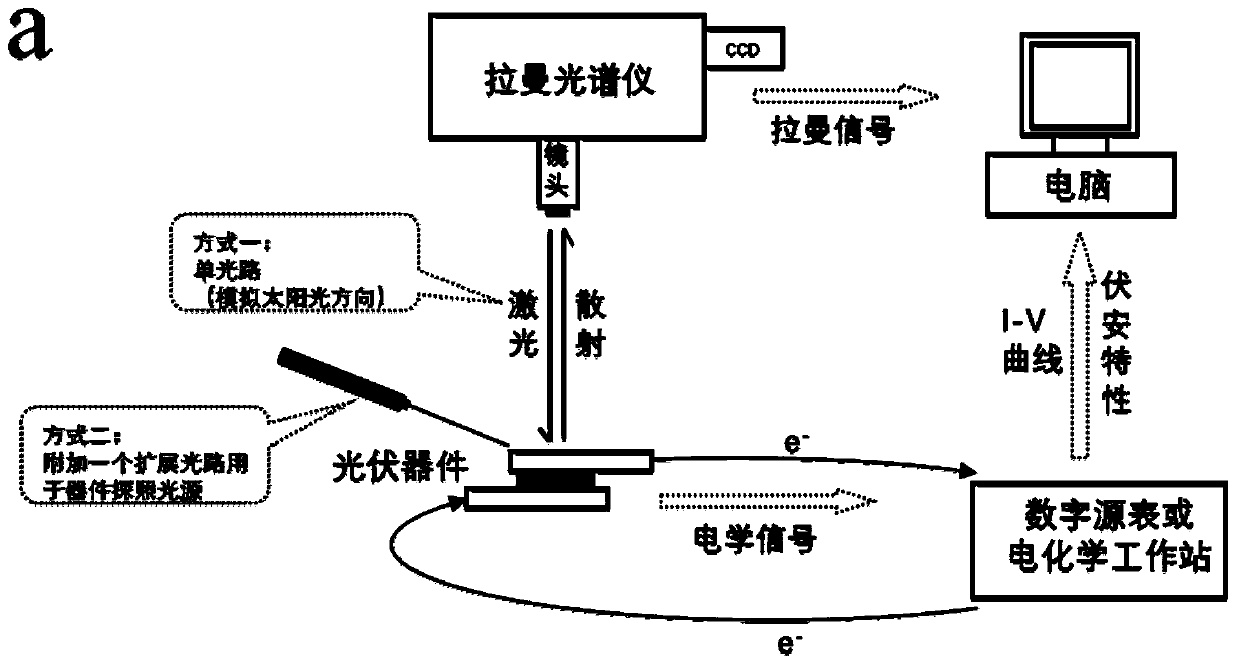

Method used

Image

Examples

Embodiment 1

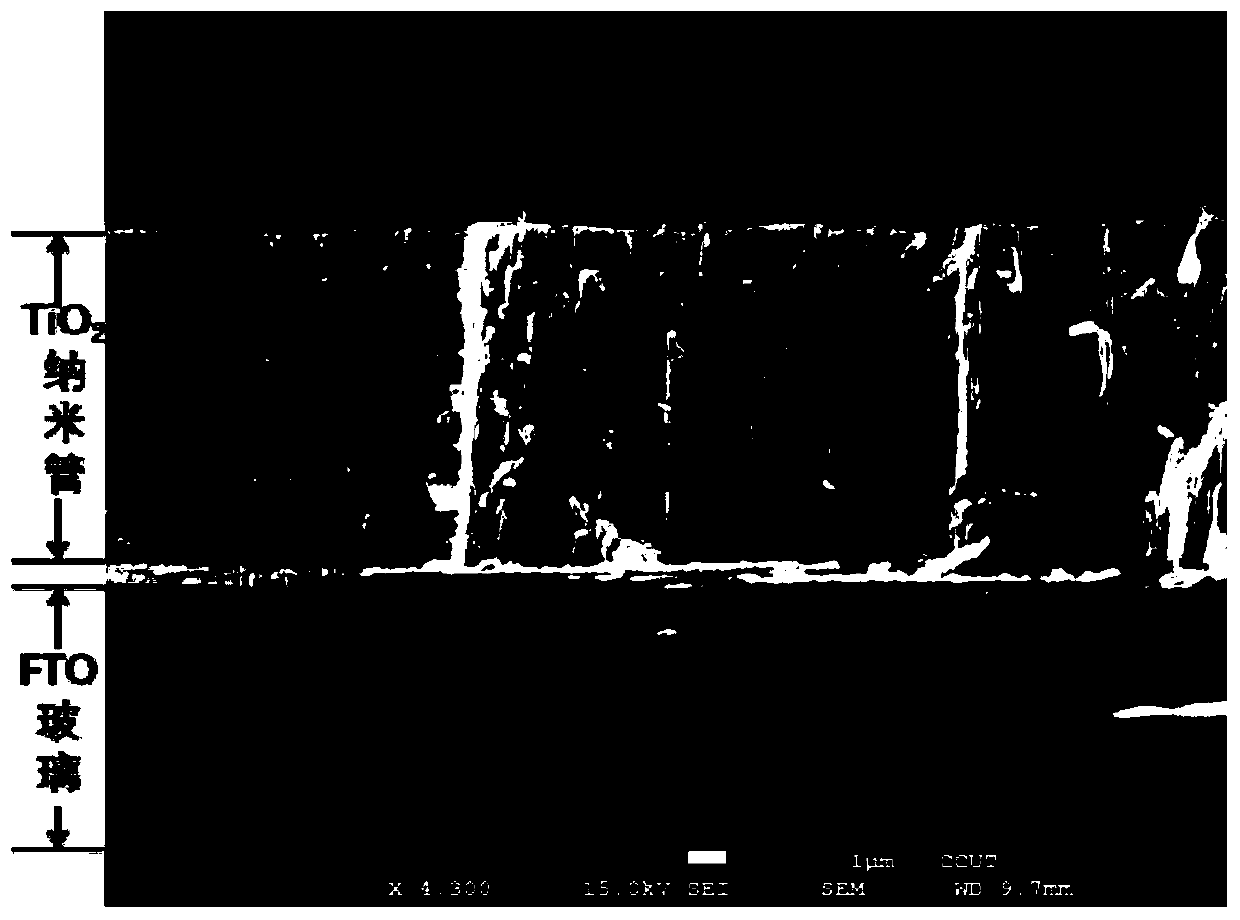

[0084] 1. Preparation of titania nanotube films

[0085] Cut the titanium sheet into 4cm×5cm, place it in methanol, isopropanol, and acetone solution, ultrasonically clean it for 15 minutes, put it into the electrolyte solution containing fluoride ions for the first anodic oxidation, connect the titanium sheet to the anode, and connect the platinum sheet to the anode. The cathode is connected, the voltage is 60V, and the time is 3h.

[0086] Put the titanium dioxide nanotube film after primary oxidation in deionized water, dry it with nitrogen gas until the film falls off, and place the above-mentioned titanium substrate in a solution containing fluorine ions for the second oxidation, the oxidation voltage is 60V, and the time is 2h.

[0087] 2. Exfoliation of titania nanotubes from titanium substrates

[0088] The secondary oxidized titanium dioxide nanotubes were calcined in a muffle furnace at a calcination temperature of 450° C. and a calcination time of 2 h. After calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com