Failure prediction method of rod pumping system based on indicator diagram

A system failure and prediction method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as system deviation from normal state, abnormal output, degradation or failure, and achieve high prediction efficiency and accuracy, The effect of improving the accuracy of prediction and improving the accuracy of prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

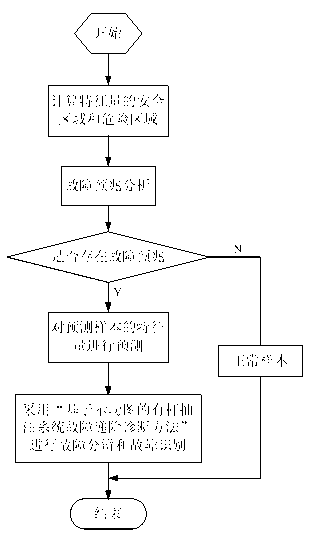

[0039] The present invention aims at the present situation that there are very few researches and applications on fault prediction of the rod pumping system, takes the normal (or steady state) sample ground dynamometer chart as the entry point, and provides a rod pumping system fault based on the dynamometer chart For the prediction method, on the basis of the failure omen analysis, the ARMA time series model is used to predict the characteristic quantities of the prediction samples, and finally the "Dynamic Diagram-Based Fault Hierarchical Diagnosis Method for Rod Pumping System" is used for fault resolution and fault identification . The invention realizes the prediction of the future development trend of the state of the sucker rod by using the characteristic quantity sequence of the indicator diagram representing the state of the sucker rod pumping system, and has high prediction efficiency and precision, especially for gradual or concentrated fault types.

[0040] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com