Electric connector and assembling method

A technology of electrical connectors and assembly methods, which is applied to the components, connections, and assembly/disassembly of contact pieces of connection devices, which can solve the problem of high-frequency signal transmission distortion, small characteristic impedance between terminals, which is not conducive to ensuring high Frequency signal transmission and other issues, to achieve the effect of increasing the characteristic impedance and convenient assembly method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

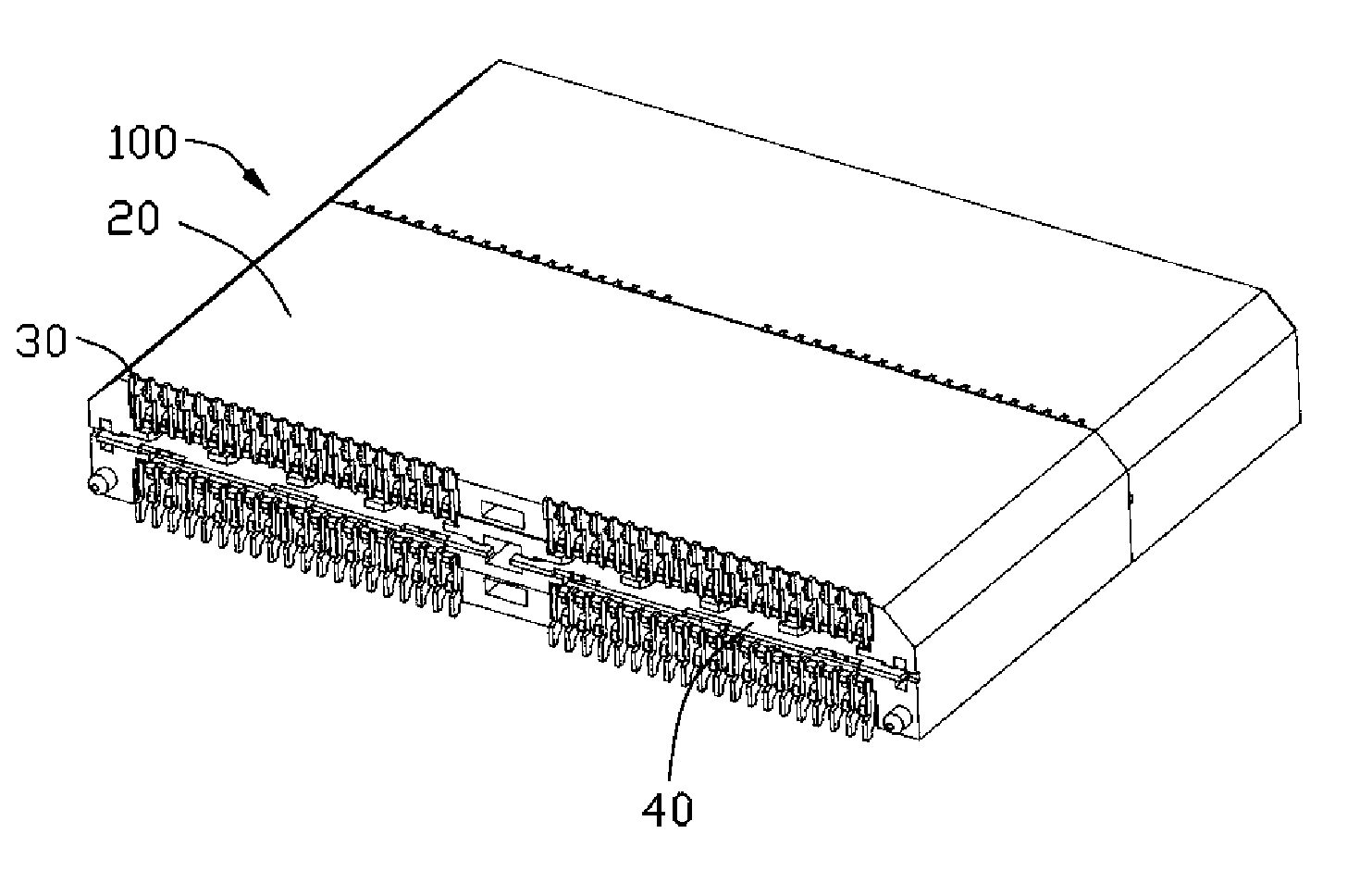

[0029] see Figure 1 to Figure 6 , is the first embodiment of the electrical connector 100 of the present invention.

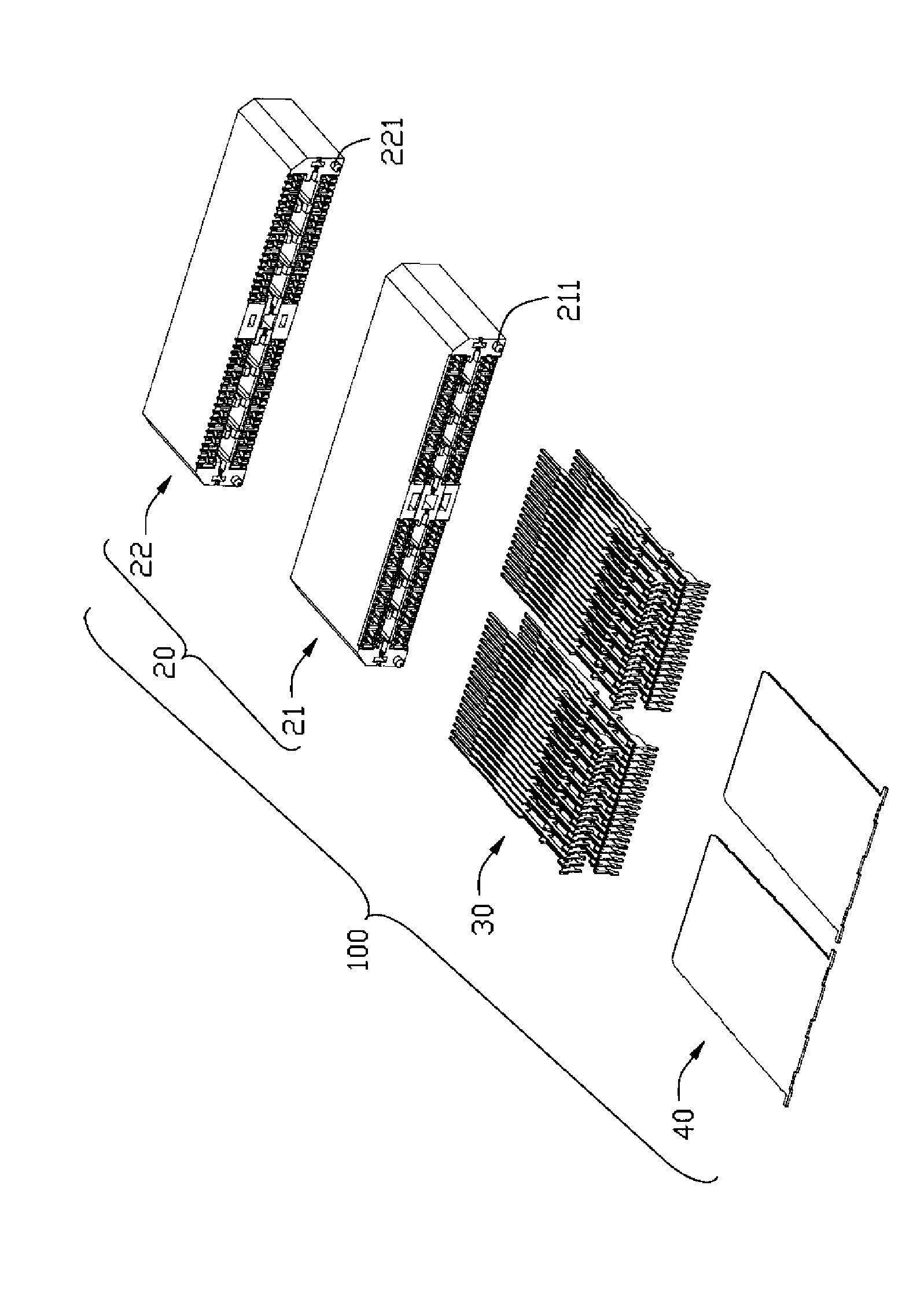

[0030] see figure 1 and figure 2 As shown, the present invention provides an electrical connector 100 mounted on a circuit board (not shown) for connecting with a counterpart (not shown) and achieving electrical contact. The electrical connector 100 includes: an insulating body 20 , a plurality of terminals 30 accommodated in the insulating body 20 , and a metal plate 40 accommodated in the insulating body 20 .

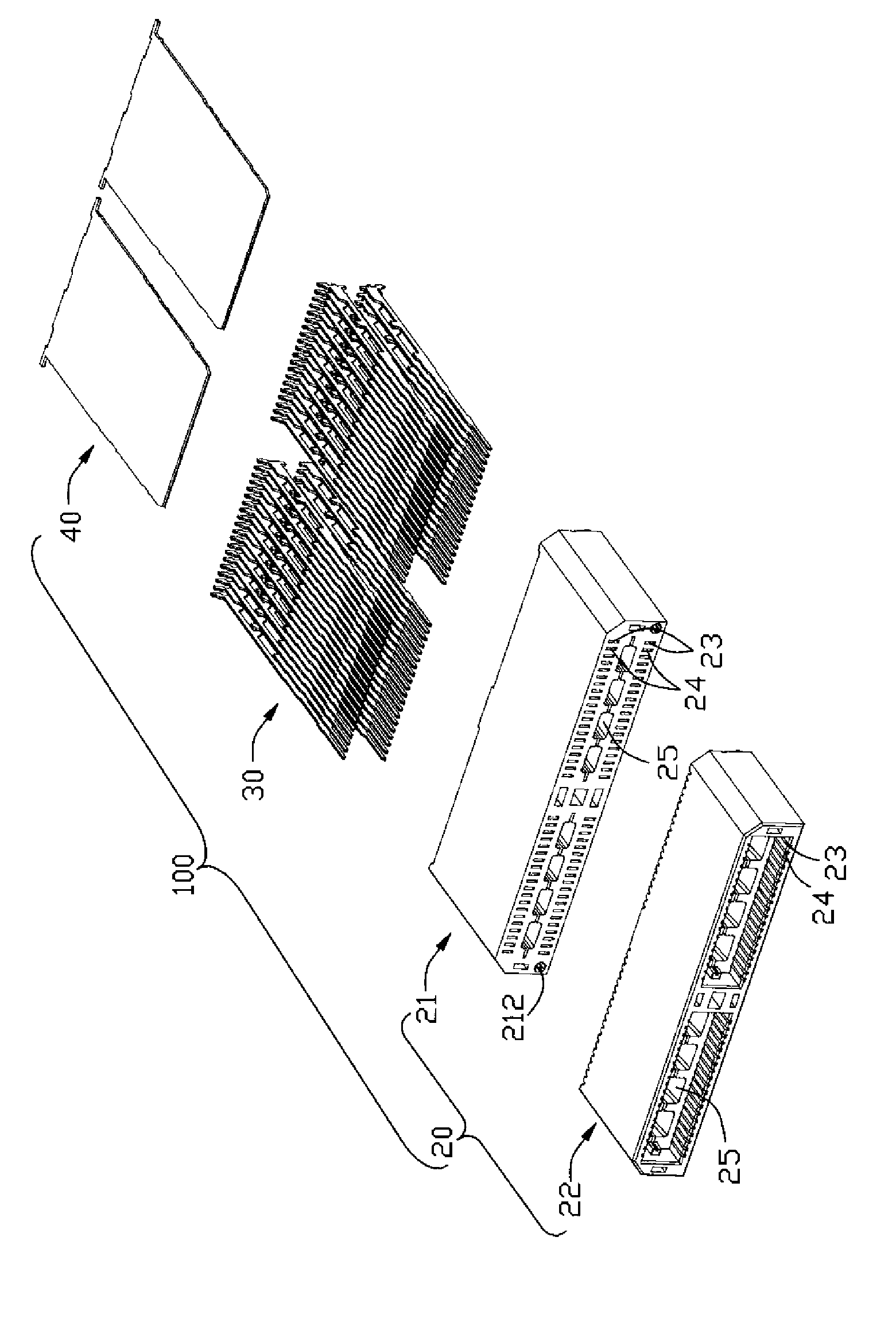

[0031] see figure 2 and image 3 As shown, the insulating body 20 includes a first insulating body 21 mounted on a circuit board (not shown) and a second insulating body 22 stacked on the first insulating body 21 . The first and second insulating bodies 21 and 22 each have first terminal grooves 23 and second terminal grooves 24 alternately accommodating terminals 30 , and first terminal grooves 24 arranged at the bottom of the first and second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com