Plugging tool for dismounting MCX bent connector

A plug-in tool and connector technology, which is applied in the connection/disconnection direction of the connection device, can solve the problem that the MCX bent connector cannot be disassembled, and achieve the effects of occupying a small space, reducing the probability of damage, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

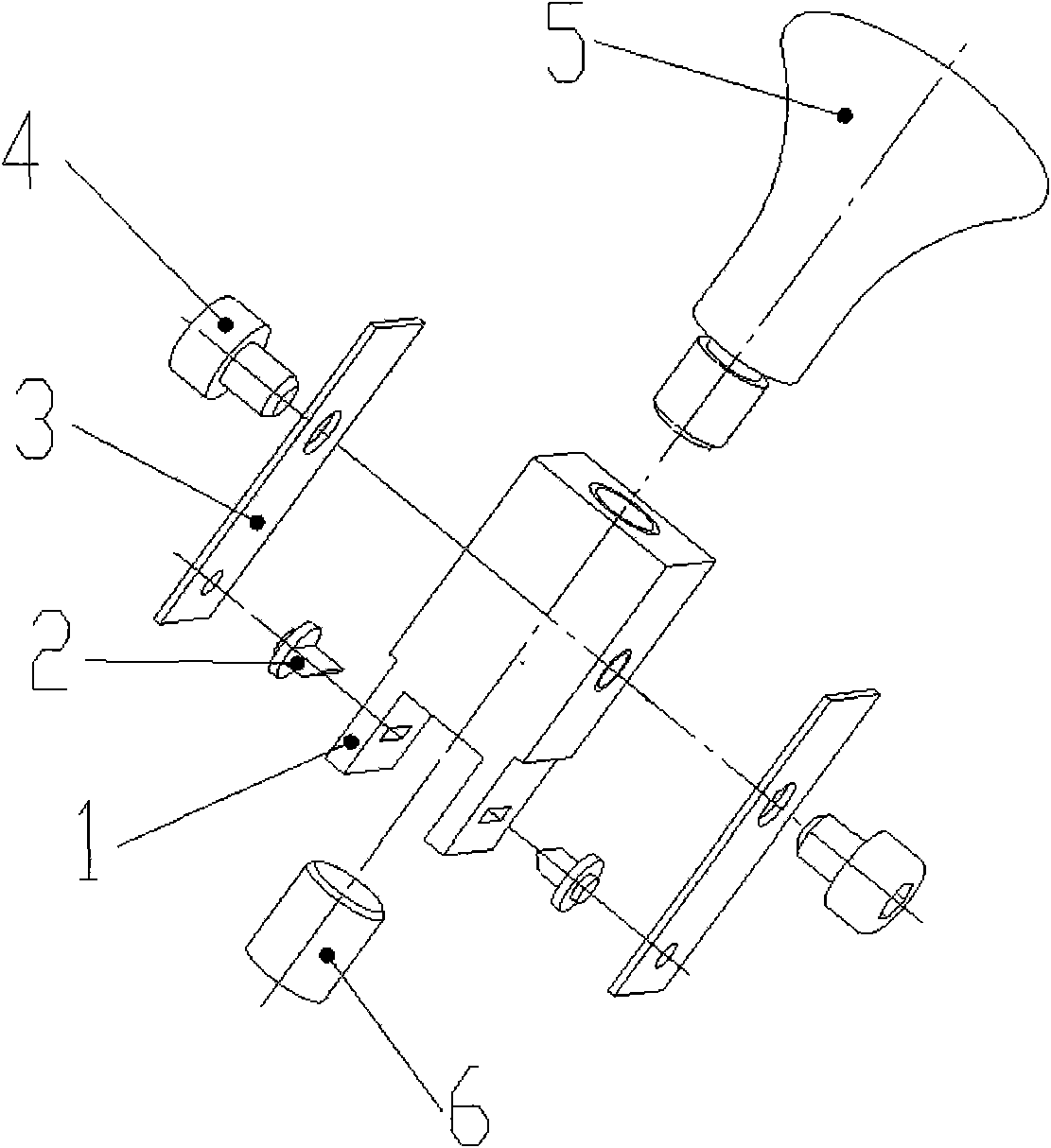

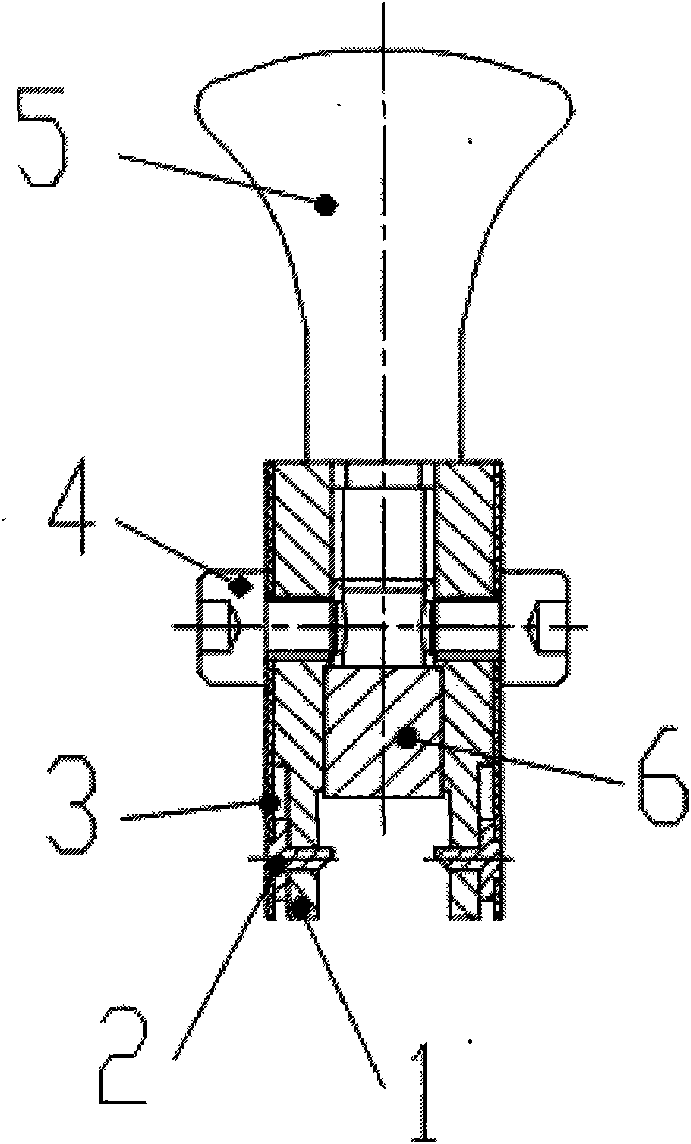

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

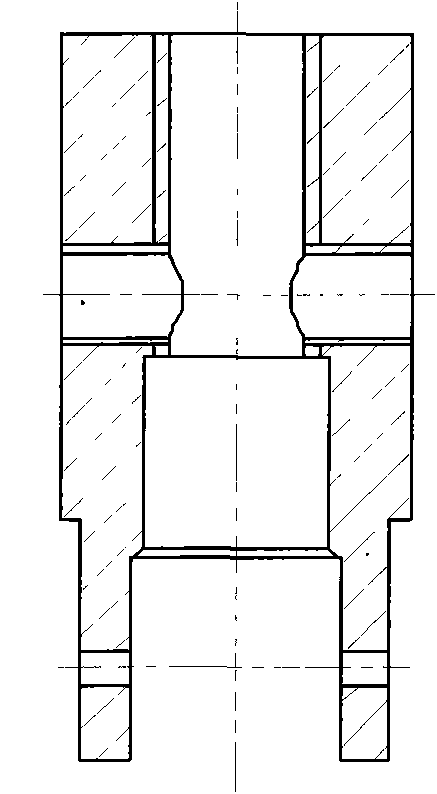

[0026] image 3 It is a schematic diagram of the structure of the housing 1 of this embodiment. The housing 1 is a square with a threaded through hole in the middle. There are threaded through holes for installing the reed 3 on both sides of the middle, and the two sides of the lower end are relatively thin small cuboids. The square through hole of claw head 2;

[0027] Figure 5 It is a structural schematic diagram of the claw head 2 in the plugging tool of the present invention. The claw head 2 is a cylinder made of tool steel. The left end is provided with a small cuboid and has a guiding inclined surface. small cylinder;

[0028] In this embodiment, the claw head 3 is made of tool steel, and the contact part of the inclined surface is ground; the plug 6 is polytetrafluoroethylene; the reed 3 is made of beryllium bronze, and then undergoes aging treatment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com