Diode clamping three-level frequency converter

A technology of three-level frequency converter and diode clamping, which is applied in the transformation equipment for intermediate conversion to DC, and the conversion of irreversible DC power input into AC power output, etc., which can solve the problem of large loss of switching tube and harmonic output waveform. wave, affecting the overall performance of diode-clamped three-level inverters, etc., to achieve the effects of improving quality, reducing switching losses, and reducing changes in distributed parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained in conjunction with the drawings:

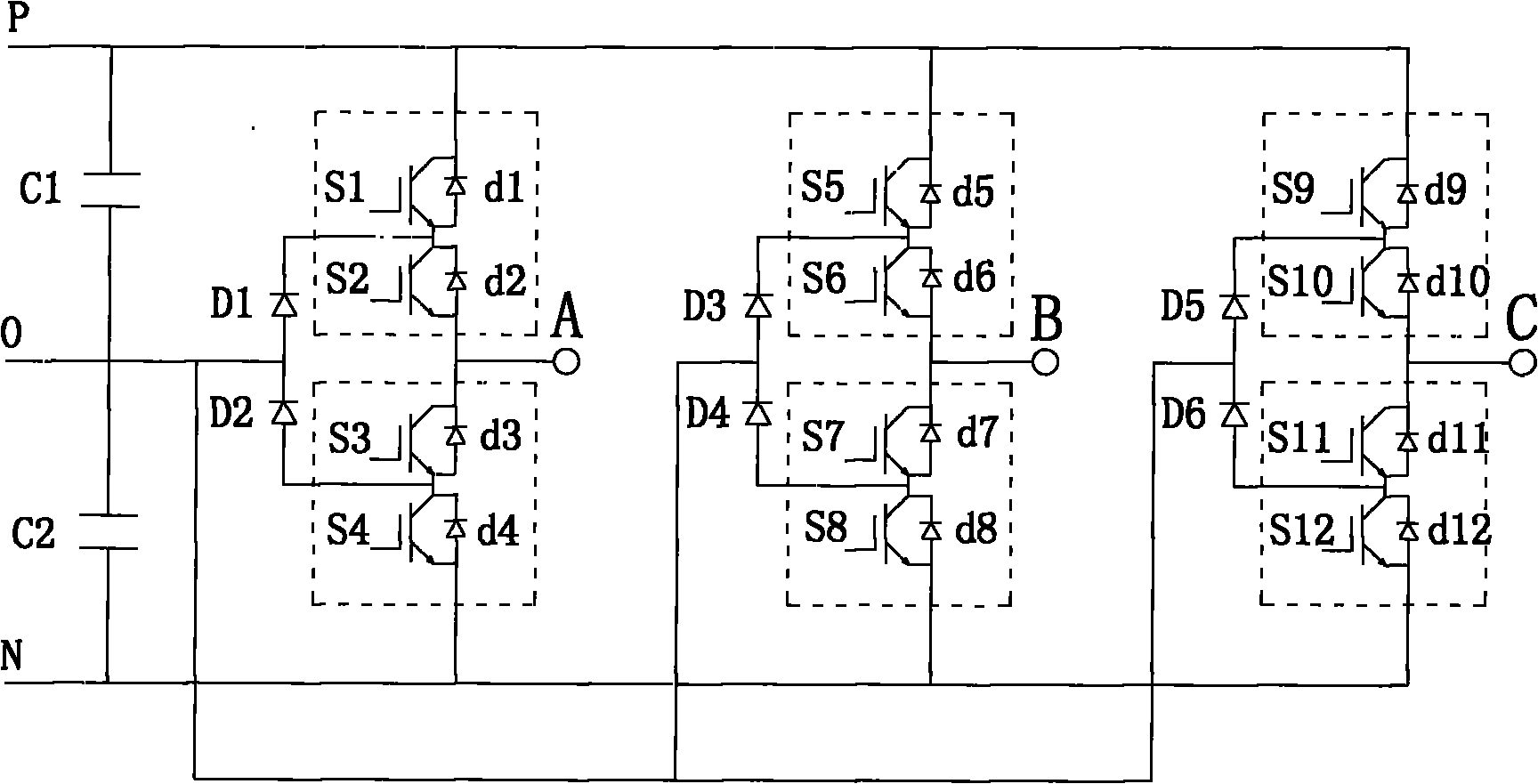

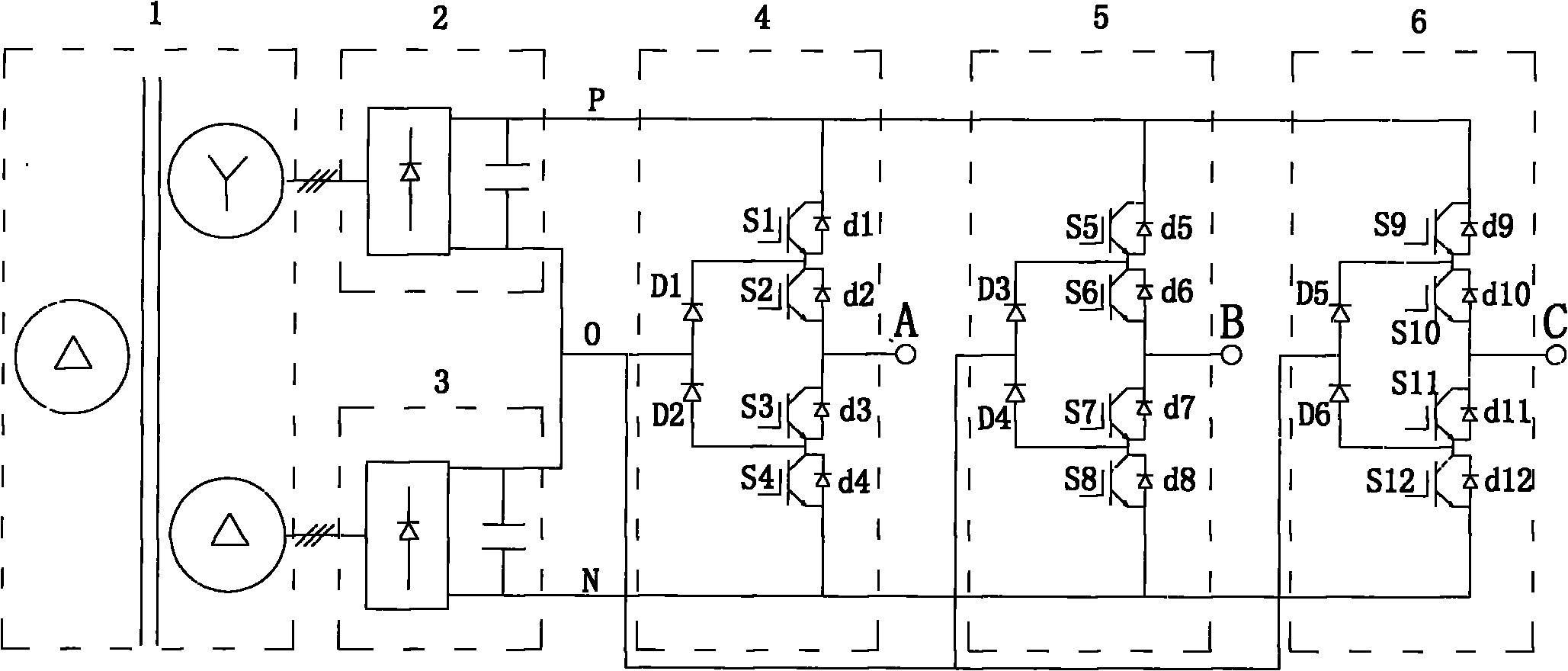

[0011] Combine figure 2 , image 3 , A diode-clamped three-level inverter, mainly composed of a 12-pulse rectification link and a three-phase H-bridge power inverter unit, characterized in that the 12-pulse rectification link consists of a phase-shifting transformer 1 and two The diode full-bridge rectifier unit is composed together; the phase-shifting transformer 1 has two secondary windings, respectively a star connection and a delta connection, and the phase difference is 30°. The line voltage of the secondary winding is the line voltage of the primary winding. Half; the DC output ends of the two rectifiers 2 and rectifier 3 are connected in series, and the series point is drawn as the midpoint; 12-pulse rectification is beneficial to eliminate harmonics and improve the utilization rate of the power grid. 4, 5, and 6 are A, B, C three-phase H-bridge power inverter units, which are main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com