Method and device for de-gassing a liquid-gas-mixture

A liquid gas and mixture technology, which is applied in the field of X-ray system and the preparation of rigid foam materials, can solve the problems of insufficient degassing effect and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

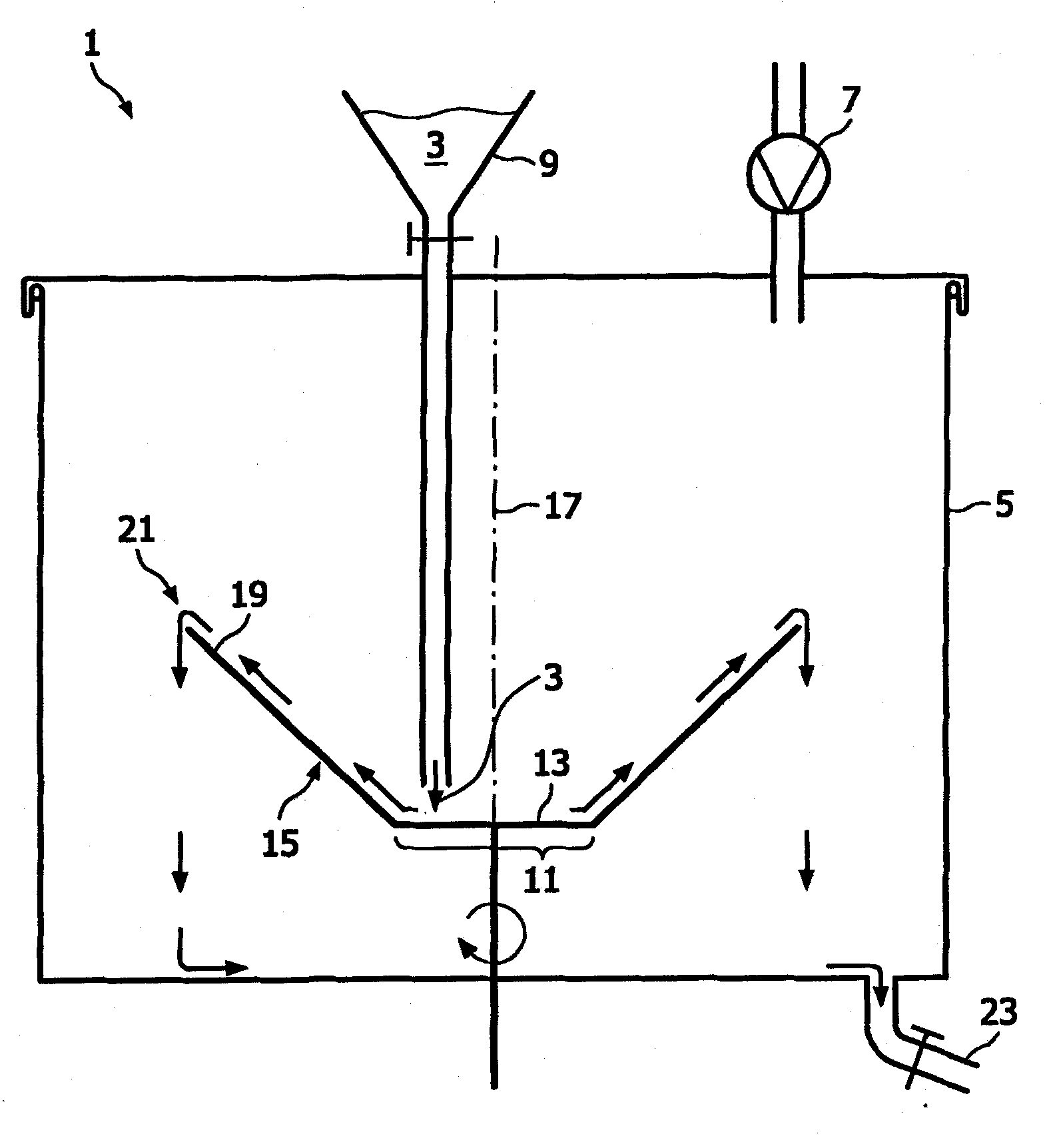

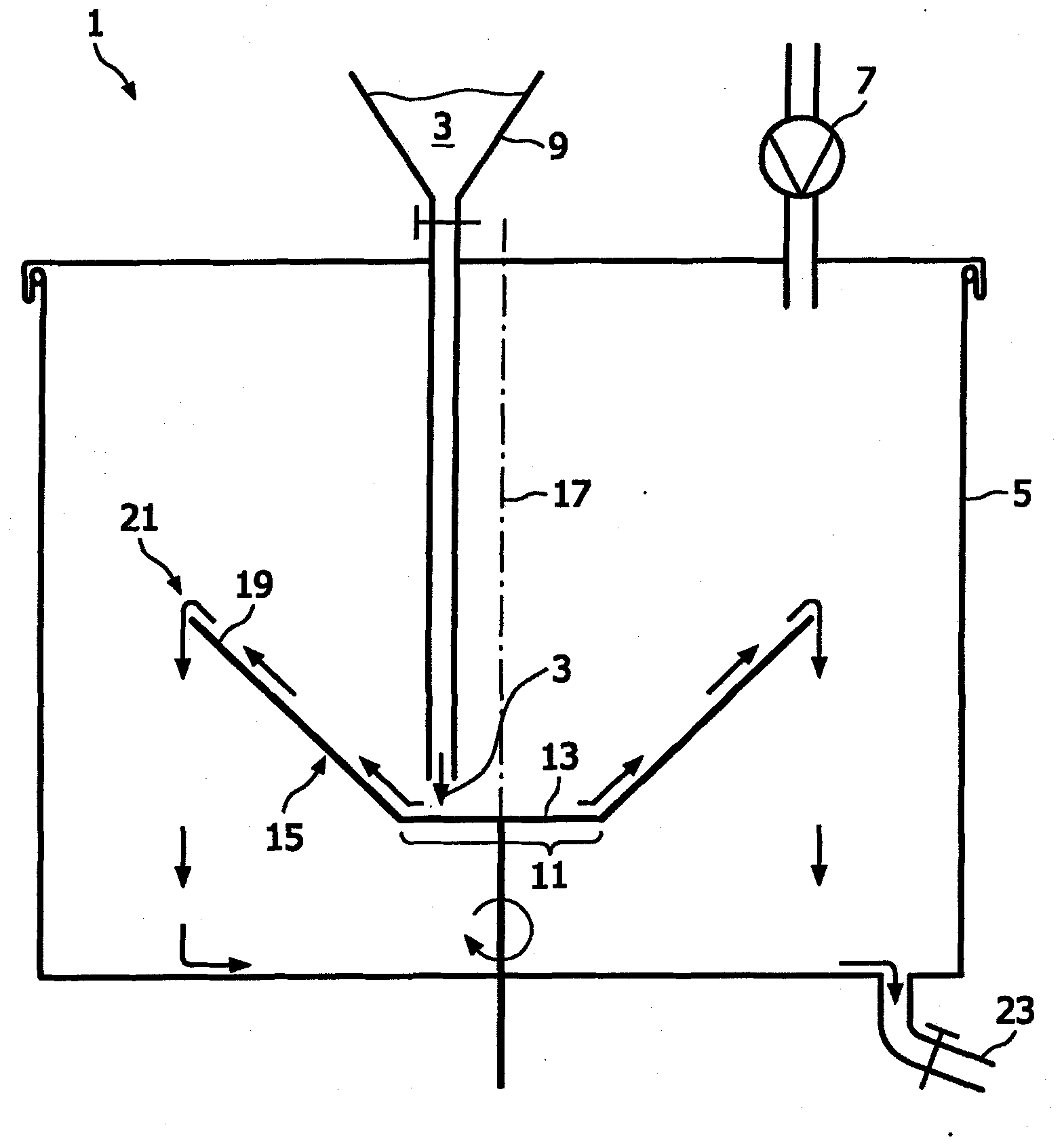

[0043] figure 1 In , a device 1 for degassing a liquid-gas mixture 3 is described. The device 1 comprises a chamber 5 , the interior of which can be brought to a reduced pressure of 5 hPa by means of a vacuum pump 7 . The liquid-gas mixture 3 can be introduced into the chamber 5 via a supply device 9 . The supply device 9 can be a simple valve or a metering pump. The supply means 9 are arranged such that the liquid-gas mixture 3 supplied to the chamber 5 drops onto the central area 11 of the inner surface 13 of the rotating body 15 .

[0044] The rotating body 15 is a frustoconical body which tapers downwards and is open at the top. When the rotating body 15 rotates rapidly about the axis of rotation 17 which coincides with its axis of symmetry, the liquid-gas mixture 3 is forced outwards by centrifugal force. The flow of the liquid-gas mixture 3 is schematically depicted in the figure by arrows. The liquid-gas mixture 3 flows and spreads along the entire inclined inner s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com