A medical guide wire, a method of making the same, an assembly of microcatheter and guiding catheter combined with the medical guide wire

A technology of guide wires and wires, applied in the direction of catheters, guide wires, etc., can solve problems such as no technical opinions, no head plugs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the description of the embodiments shown below, the same reference numerals are used for the same types of features.

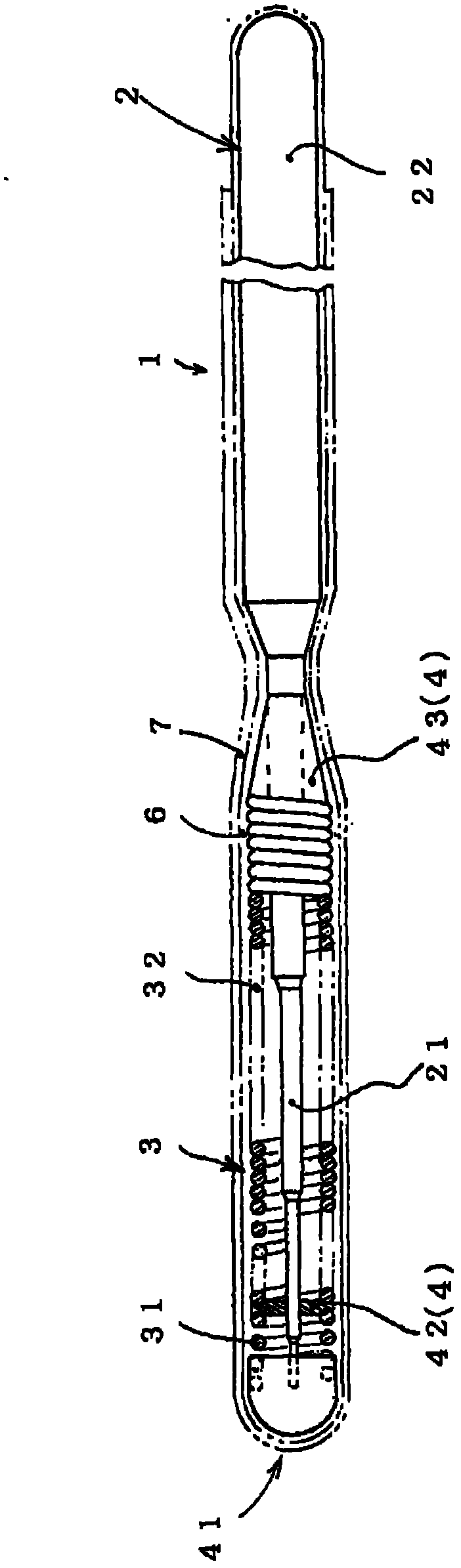

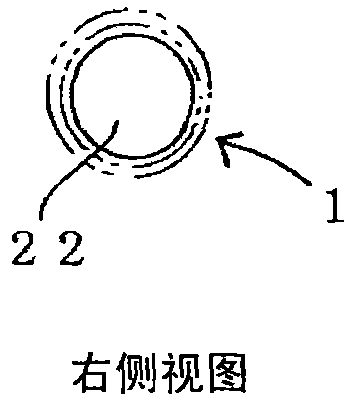

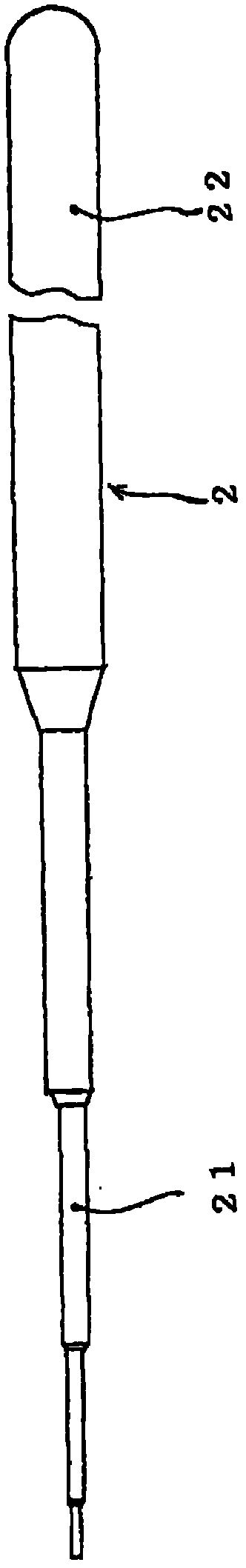

[0053] refer to Figures 1 to 14 , which shows a medical guide wire 1 (abbreviated as "guide wire 1" in the afternoon) according to the first embodiment of the present invention.

[0054] The guide wire 1 has a core wire 2 formed from an elastic elongate element. The core wire 2 has a distal portion 21, such as Figures 1 to 4 As shown, the helical spring body 3 is arranged coaxially around the core wire 2 .

[0055] The helical spring body 3 has a distal portion as a shielding radiation coil 31 made of silver, platinum, tungsten or the like.

[0056] At the front welding section 41 , the middle welding section 42 and the tail welding section 43 , each of which is designated by the distal portion 21 of the core wire 2 , the core wire 2 and the helical spring body 3 are partly fixed by the welding element 4 .

[0057] Such as Figure 5 , 6 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com