PVC-U (Unplasticized Poly Vinyl Chloride) hollow-wall internal-screw sound absorbing tube and preparation method thereof

A technology of PVC-U and sound-absorbing pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc. It can solve the problems that the sound-absorbing effect cannot be achieved, and the pipe quality is not ideal, so as to improve the drainage capacity and stabilize the pressure. Fluctuation, the effect of reducing the drag coefficient of the water tongue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

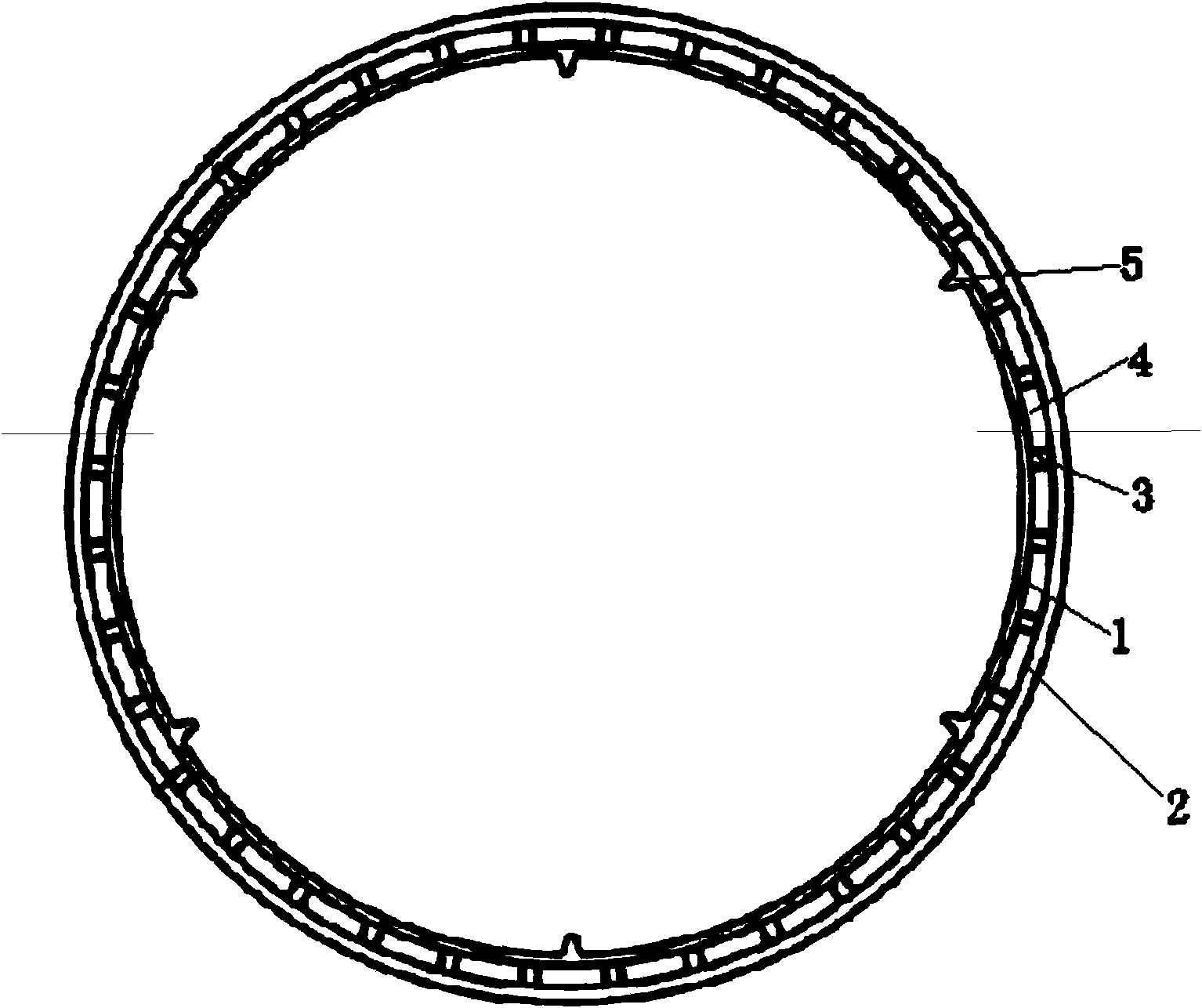

[0027] Example: see figure 1 , the present invention a kind of PVC-U hollow wall internal spiral noise-absorbing pipe material preparation method, it comprises the following steps:

[0028] 1) Prepare an extrusion die, the die cavity of the extrusion die is set as a cylinder with both ends open, and several grooves are evenly spaced toward the center of the die cavity on the inner surface of the cylinder. Several ribs are evenly spaced in the circumferential direction, and the inclination direction of the ribs is adjustable, so that the thickness of the inner and outer walls of the spiral sound-absorbing pipe in the hollow wall can be adjusted according to the design requirements, and the extrusion die is fixed on the extruder;

[0029] 2) Batching, mixing PVC resin, thermally stable lubricant, filler, processing aid and pigment in proportion;

[0030] 3) Mixing, put it into the high-speed mixer after batching, and under the agitation of the high-speed propeller blade, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com