Waste gas protection system for thermal treatment furnace and control method

A protection system, heat treatment furnace technology, applied in the maintenance of heating chamber, furnace, furnace components, etc., can solve the problems of high nitrogen consumption, high manufacturing and use costs, large power consumption, etc., to achieve stable atmosphere and reduce air entry Effects in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

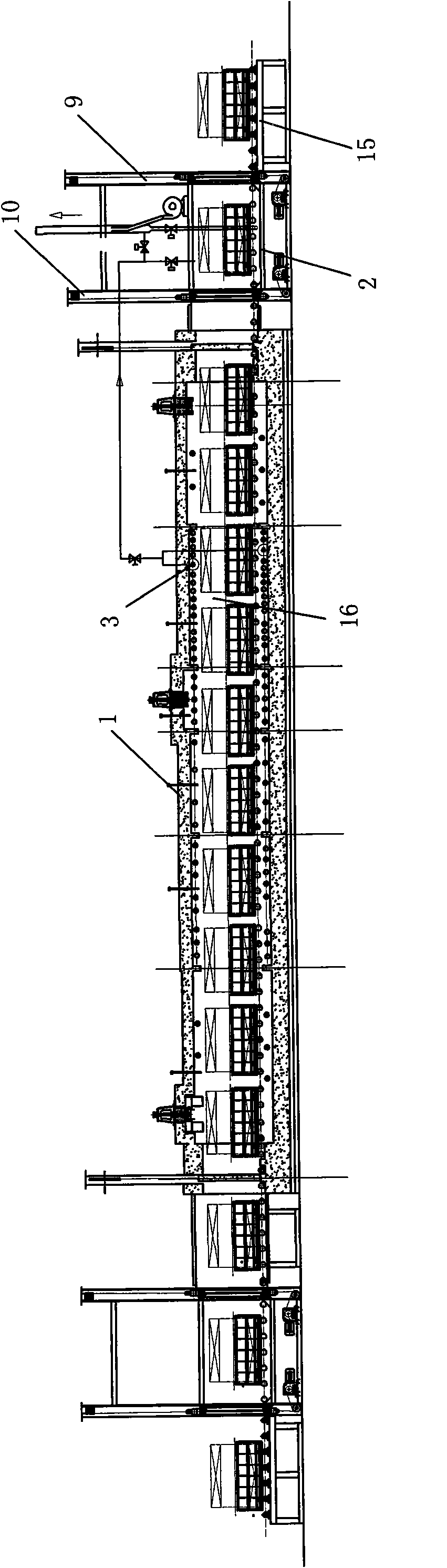

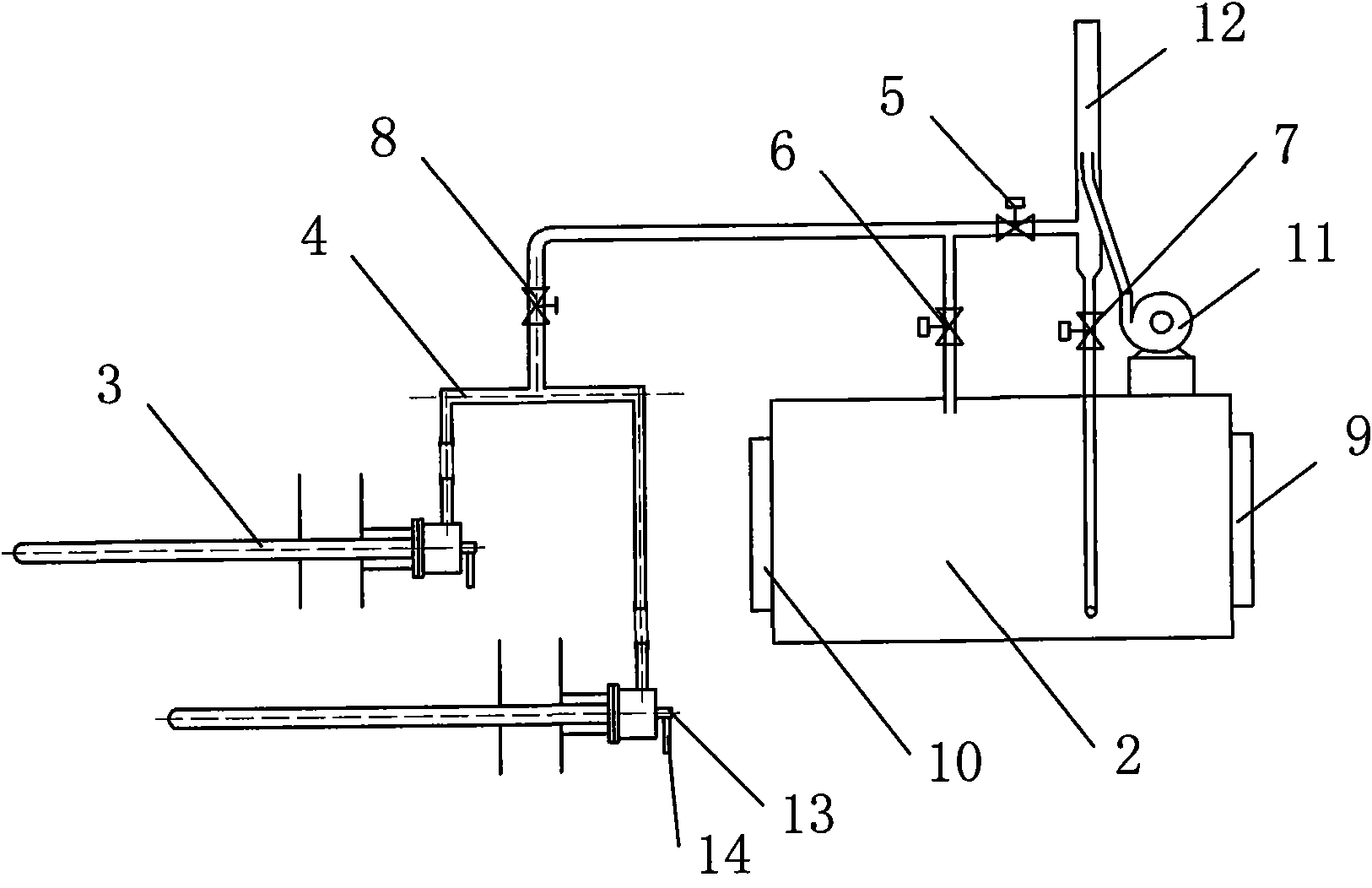

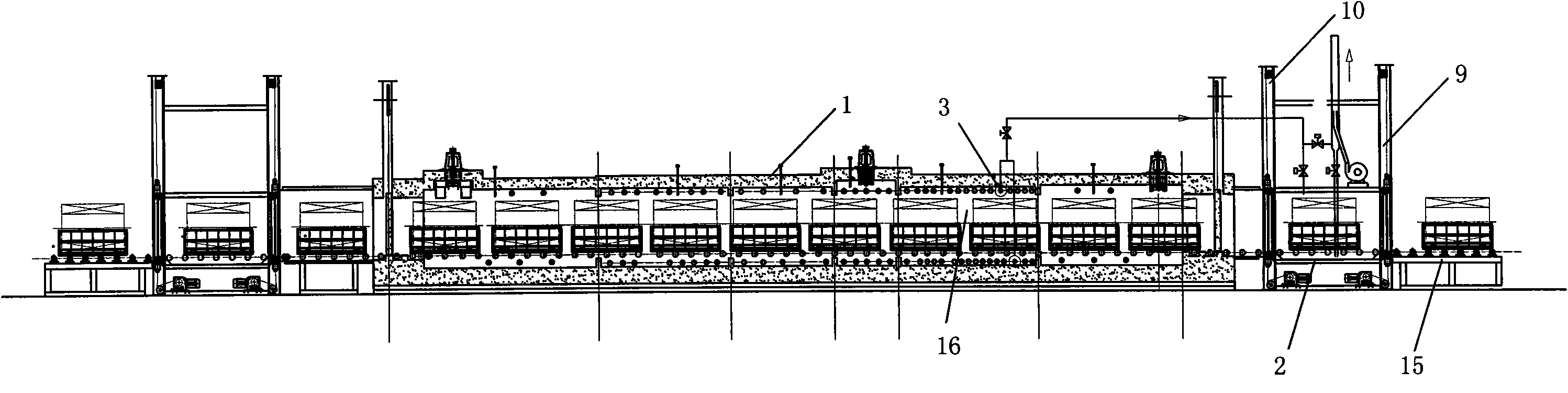

[0017] Such as figure 1 and figure 2 As shown, this exhaust gas protection system for a heat treatment furnace includes a furnace body 1 and a feed platform 15, an air replacement chamber 2 is arranged between the inlet of the furnace body 1 and the feed platform 15, and the air replacement chamber 2 and the inlet A No. 1 door 9 is provided between the material table 15, and a No. 2 door 10 is provided between the air replacement chamber 2 and the entrance of the body of furnace 1; the gas radiant pipe 3 in the heating chamber 16 part of the body of furnace 1 passes through the exhaust pipe 4 and The input ends of the fourth valve 8 are connected. The gas radiant pipe 3 includes a gas inlet 13 and an air inlet 14. This embodiment is divided into two groups, one group is arranged above the inner wall of the furnace body 1, and the other group is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com