Floor slab buckle connection structure

A technology for connecting structures and floors, which is applied in the field of building decoration materials, can solve the problems of increased floor manufacturing costs, floor damage and scrapping, and additional floors, and achieves the effect of low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

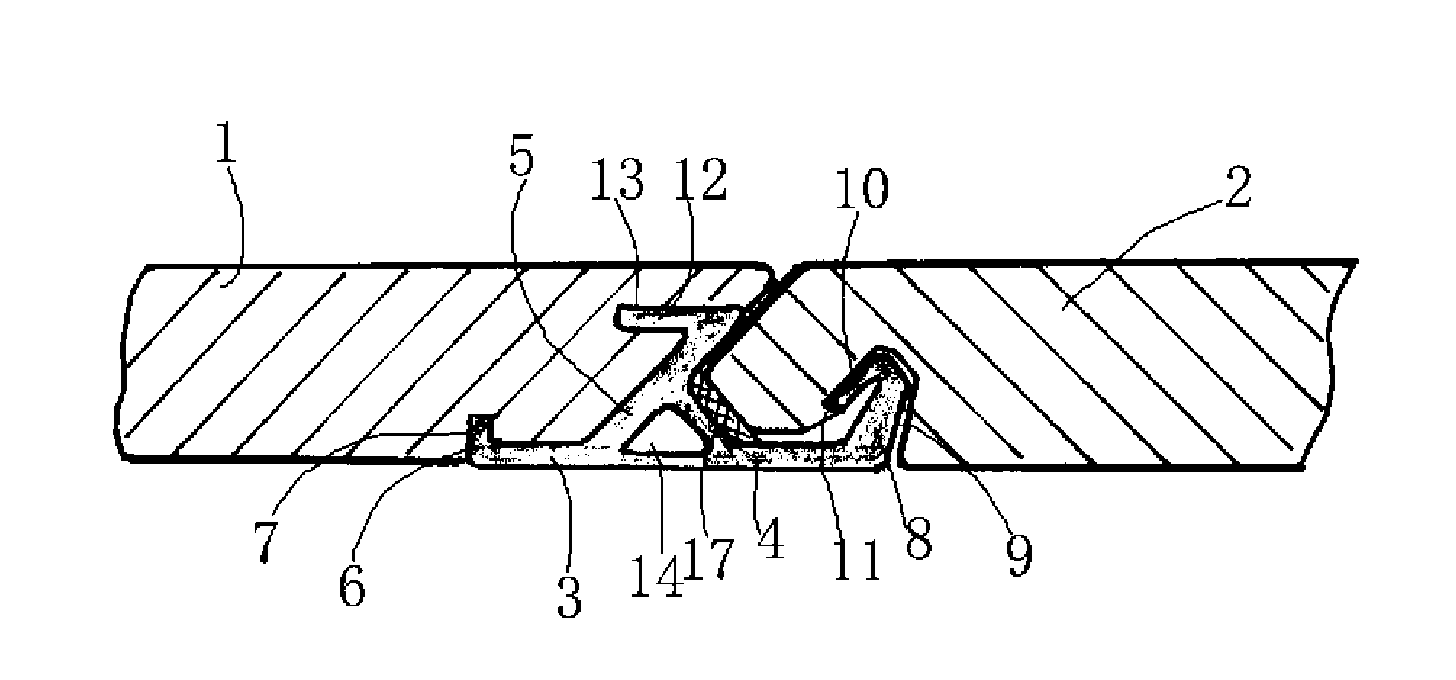

[0020] Embodiment 1: as figure 1 As shown, it includes the adjacent first floor 1 and the second floor 2, and the first floor 1 and the second floor 2 are connected to each other through the connecting piece 3 processed by the profile, and the connecting piece 3 includes a transverse part 4 and a transverse part 4 The upper convex part 5 integrally formed on the top, the bottom surface of the horizontal part 4 is flush with the bottom surface of the first floor and the bottom surface of the second floor, the connecting part 3 is bonded and fixed to the first floor 1, and the horizontal part 4 is connected to the first floor The corresponding end forms a lower first buckle portion 6 that is upturned, and a lower first buckle groove 7 corresponding to the lower first buckle portion 6 is formed on the bottom surface of the first floor, and the lower first buckle portion 6 Extending vertically upwards; the end of the horizontal part 4 corresponding to the second floor 2 forms a lo...

Embodiment 2

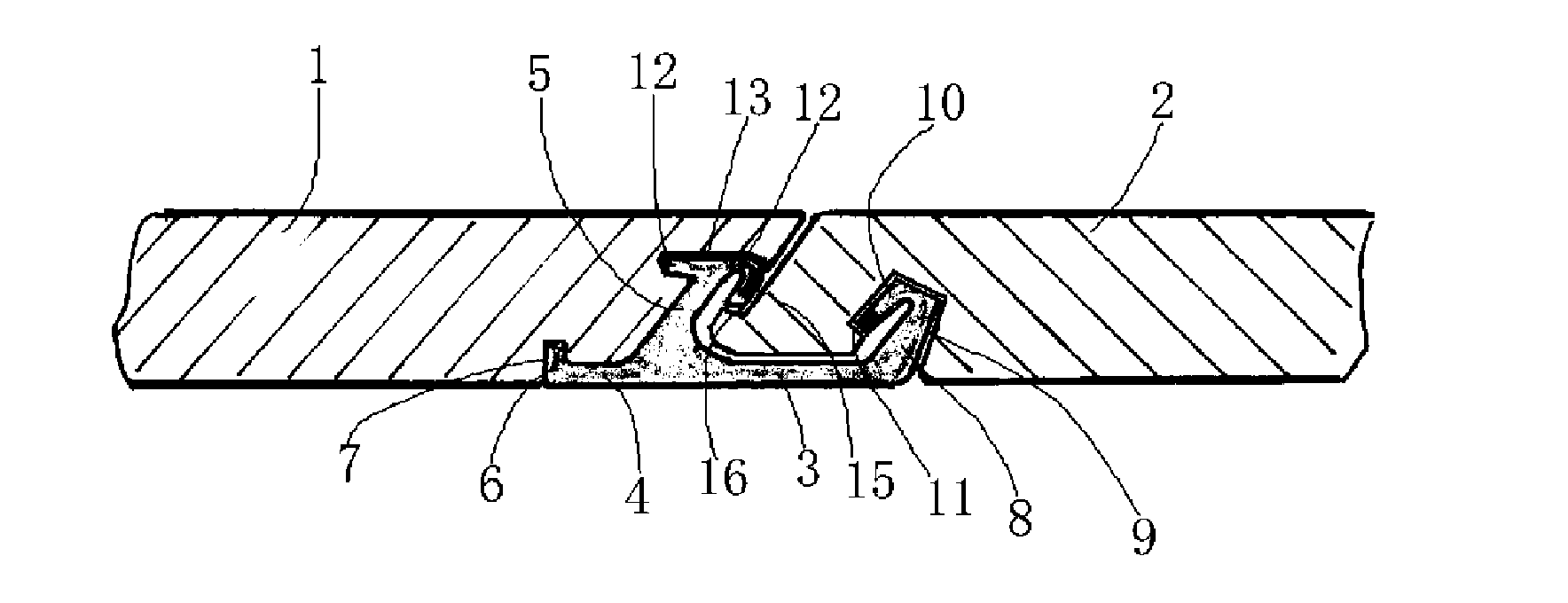

[0021] Embodiment 2: as figure 2As shown, it includes the adjacent first floor 1 and the second floor 2, and the first floor 1 and the second floor 2 are connected to each other through the connecting piece 3 processed by the profile, and the connecting piece 3 includes a transverse part 4 and a transverse part 4 The upper convex part 5 integrally formed on the top, the bottom surface of the horizontal part 4 is flush with the bottom surface of the first floor 1 and the bottom surface of the second floor 2, the connecting part 3 is bonded and fixed with the first floor 1, and the horizontal part 4 is connected to the second floor. One end corresponding to the floor forms a lower first buckle portion 6 that is upturned, and a lower first buckle groove 7 corresponding to the lower first buckle portion 6 is formed on the bottom surface of the first floor, and the lower first buckle The part 6 extends vertically upward; the end of the horizontal part 4 corresponding to the second...

Embodiment 3

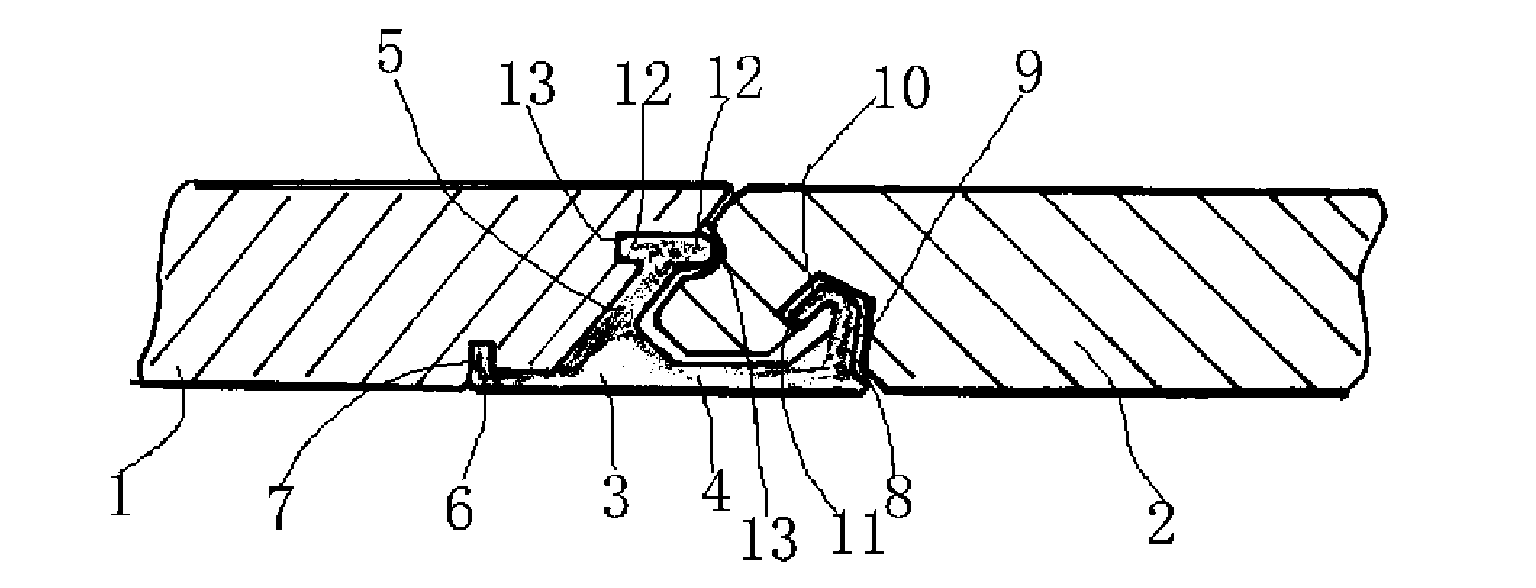

[0022] Embodiment 3: as image 3 As shown, it includes the adjacent first floor 1 and the second floor 2, and the first floor 1 and the second floor 2 are connected to each other through the connecting piece 3 processed by the profile, and the connecting piece 3 includes a transverse part 4 and a transverse part 4 The upper convex part 5 integrally formed on the top, the bottom surface of the horizontal part 4 is flush with the bottom surface of the first floor 1 and the bottom surface of the second floor 2, the connecting part 3 is bonded and fixed with the first floor 1, and the horizontal part 4 is connected to the second floor. One end corresponding to the floor forms a lower first buckle portion 6 that is upturned, and a lower first buckle groove 7 corresponding to the lower first buckle portion 6 is formed on the bottom surface of the first floor, and the lower first buckle The part 6 extends vertically upward; the end of the horizontal part 4 corresponding to the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com