Device for measuring extremely-low gas flow based on static expansion vacuum standard

A technology of gas flow and measuring devices, which is applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detection by measuring pressure difference, etc. It can solve problems such as limiting pressure accurate measurement, improve measurement accuracy and avoid measurement uncertainty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

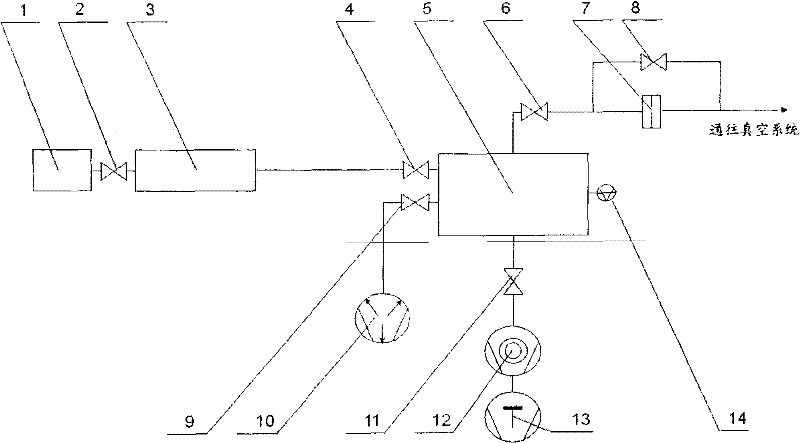

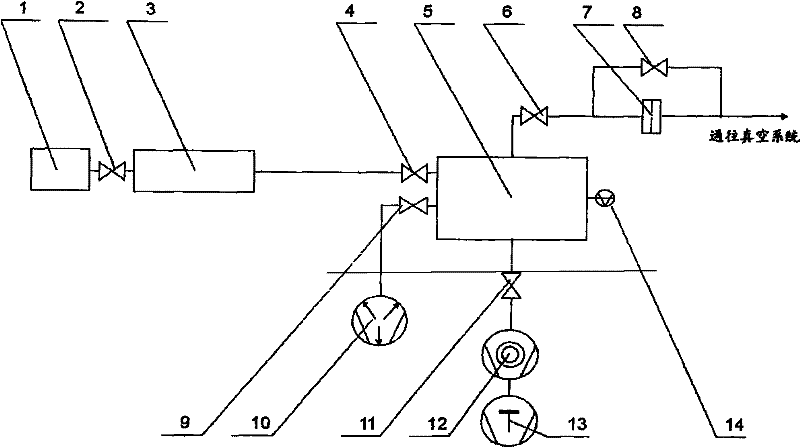

[0026] Such as figure 1 As shown, it is the extremely small gas flow measuring device based on the vacuum standard of the static expansion method of the present invention, which consists of a pre-stage pressure measurement system 1, a valve one 2, a gas pressure attenuation system 3, a valve two 4, a calibration chamber 5, and a valve three 6 , small hole 7, valve four 8, valve five 9, getter pump 10, valve six 11, molecular pump 12, backing pump 13 and ionization gauge 14.

[0027] The pre-stage pressure measurement system 1 is connected to the gas pressure attenuation system 3 through the valve one 2, the gas pressure attenuation system 3 is connected to the calibration chamber 5 through the valve two 4, the small hole 7 is connected in parallel with the valve four 8, and one end passes through the valve three 6 and the calibration chamber 5, one end is connected to the vacuum system, the getter pump 10 is connected to the calibration chamber 5 through the valve five 9, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com