Quick batch-sampling and separating device

A separation device and fast technology, applied in the direction of sampling device, etc., can solve the problems of unreported, simple structure, single function, etc., and achieve the effect of improving structural stability, easy control, and small rotational inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

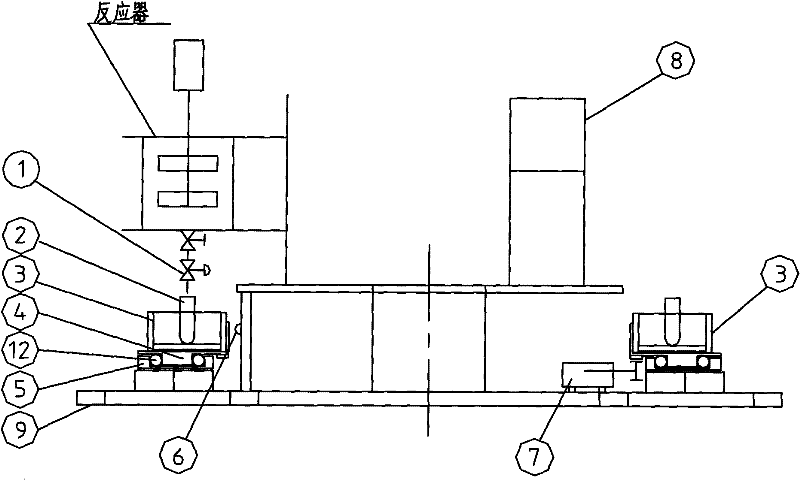

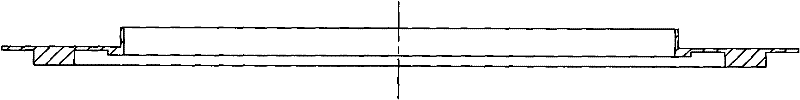

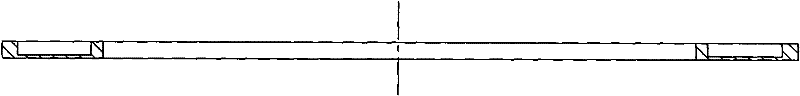

[0042] Such as Figure 1 to Figure 5 As shown, the simple rapid batch sampling device consists of a sampling valve 1, a test tube 2, a test tube rack 3, a sampling turntable 4, a turntable bracket 5, a positioning sensor 6, a driving mechanism 7, a control device 8 and a platform support 9. Wherein the sampling valve 1 is installed on the sampling tube at the bottom of the reactor, and its sampling port is opposite to the test tube 2 installed in the test tube rack 3, and the test tube rack 3 is fixed on the sampling turntable 4. The sampling turntable 4 is a circular guide rail structure, and the sampling turntable 4 relies on ball bearings Rotate on the turntable bracket 5, the turntable bracket 5 is fixed on the platform support 9 lower platforms. The positioning sensor 6 detects the installation position of the test tube rack 3 on the sampling turntable 4, and adjusts the initial state of the rapid batch sampling device through the control device 8. The driving mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com