Micron-nano thermal detecting and sensing component

A sensing component, micro-nano technology, applied in the field of instrument development, can solve problems such as structural incompatibility, and achieve the effect of improving the effective component and enhancing the detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

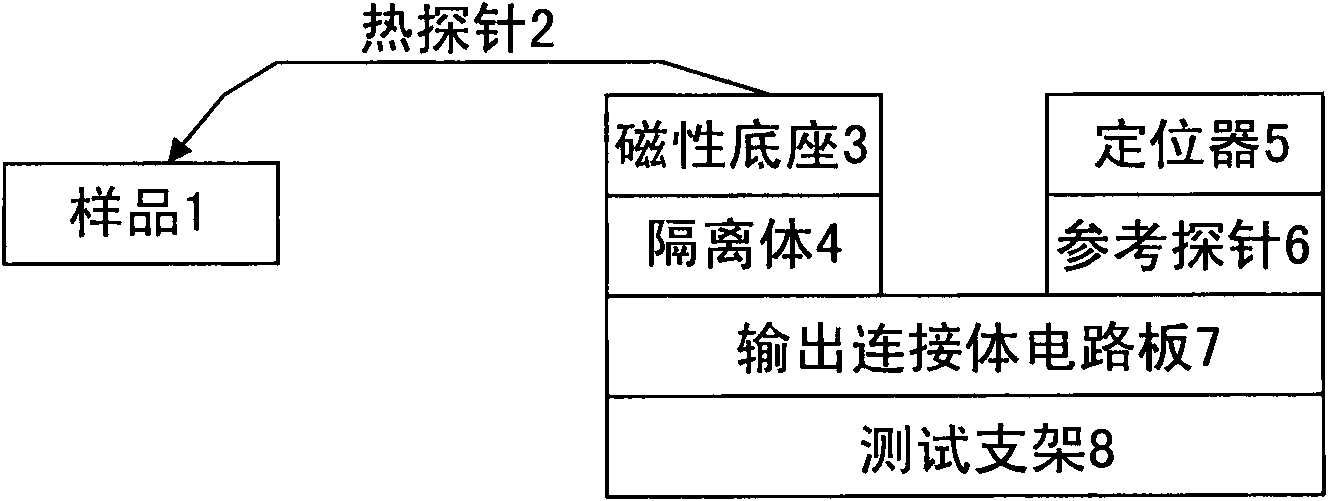

Method used

Image

Examples

Embodiment 1

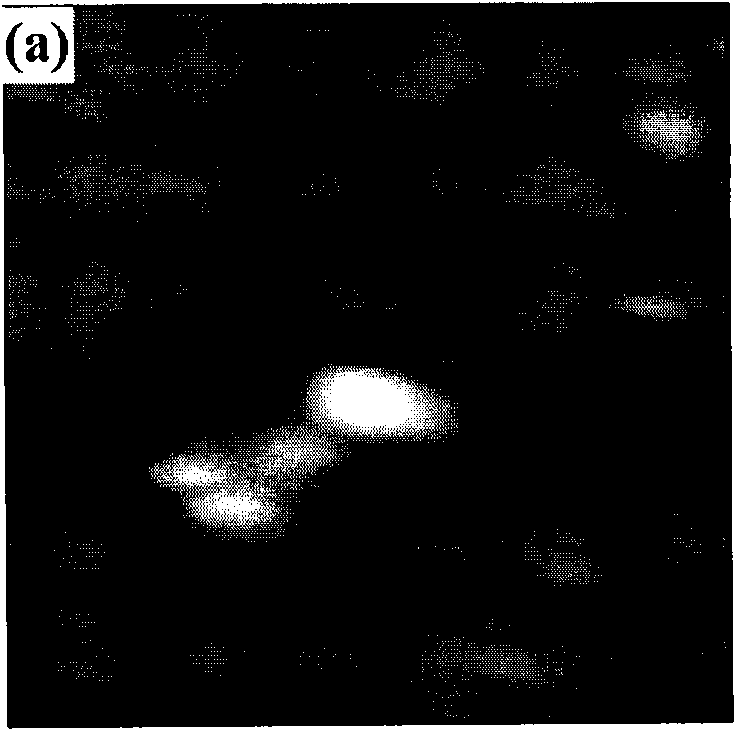

[0029] Embodiment 1: Applying the present invention to carry out thermal detection imaging on low temperature co-fired ceramics (Low Temperature Co-fired Ceramics, LTCC). LTCC is a new electronic packaging material used to achieve high integration and high performance. The devices made are widely used in the fields of high-frequency wireless communication, aerospace industry, and computers. Due to the miniaturization and high integration of devices, the thermophysical properties of their microstructures are closely related to the reliability and service life of devices. So far, there have been no reports on the detection of microscopic thermophysical properties of such materials. Figure 2 shows the test results. Among them, the picture (a) is the topographic AFM image of the sample, which is the original function of the atomic force microscope. The picture (b) is the SThM thermal image reflecting the microscopic thermal physical properties of the sample in situ by the built-u...

Embodiment 2

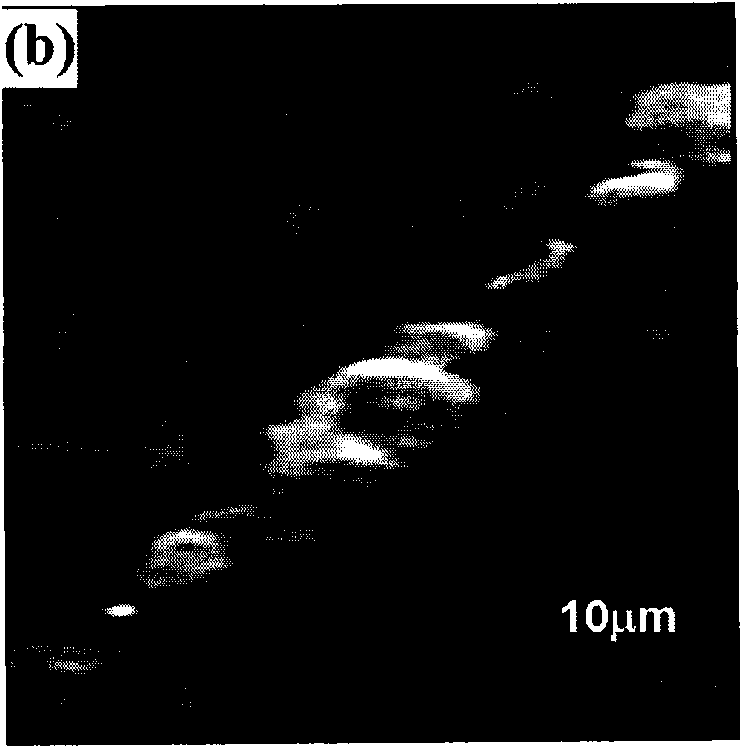

[0031] Embodiment 2: application of the present invention to ferromagnetic memory alloy Ni 53 mn 24 Ga 23 The material was thermally detected and imaged. Figure 3 shows the test results of the topographic and thermal images of the ferromagnetic alloy in the scanning range of 80 μm × 80 μm. Figure 3(a) is a topographical image, showing scratches and defects on the surface, without other information. The thermal image of Figure 3(b) shows a curved microstructure with alternating bright and dark contrasts (as indicated by the arrow). The thermal image of this structure can roughly confirm that the width of these stripes is 3-4 μm. According to the contrast mechanism of scanning thermal imaging, if the influence of the topographic image is excluded, the thermal image mainly reflects the thermal conductivity distribution of the micro-region of the sample. Figure 2 reflects the inhomogeneity of thermal conductivity in ferromagnetic alloy micro-regions, which has not been reporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com