Square-wave generator and system and method for calibratig resistance voltage divider

A square wave generator and calibration system technology, which is applied in the direction of instruments, measuring electrical variables, measuring devices, etc., can solve the problem of not meeting the requirements of the water resistance voltage divider, the calibration system of the water resistance voltage divider is not standardized, and the connection pair calibration Issues such as large impact on the results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated.

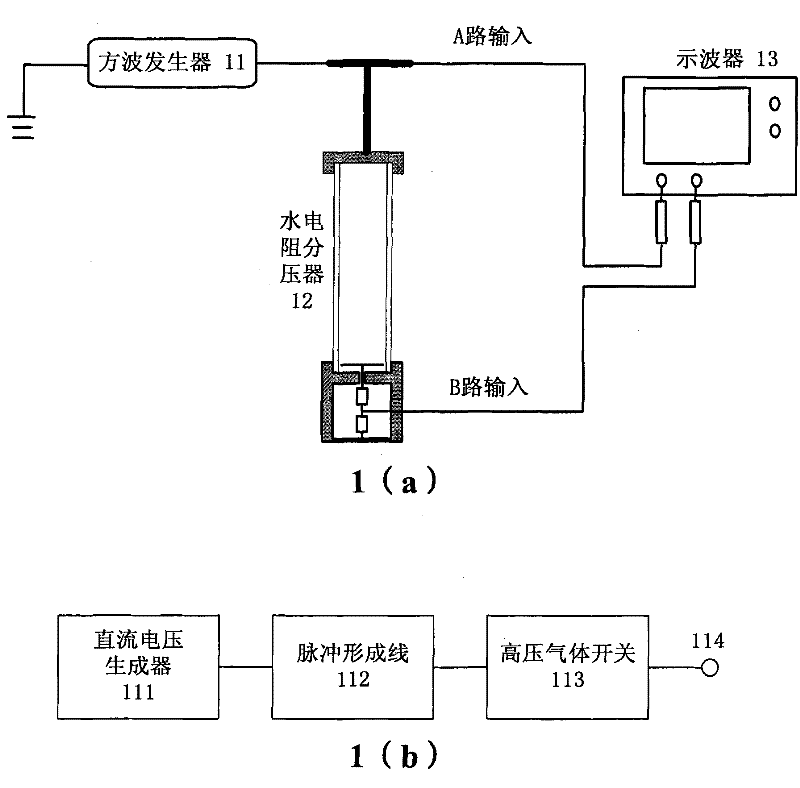

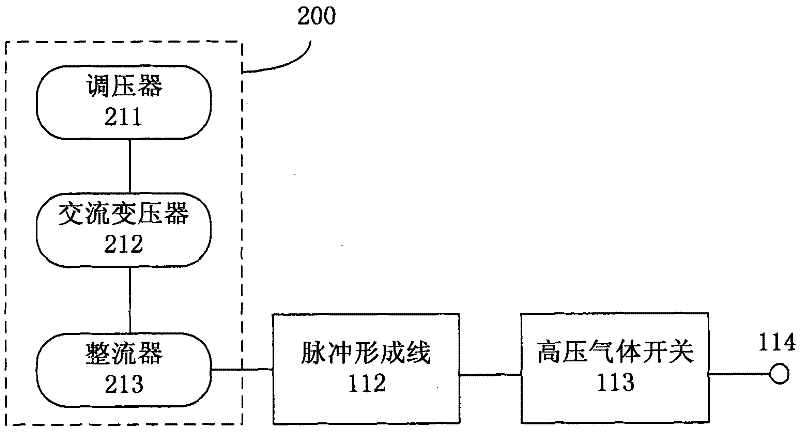

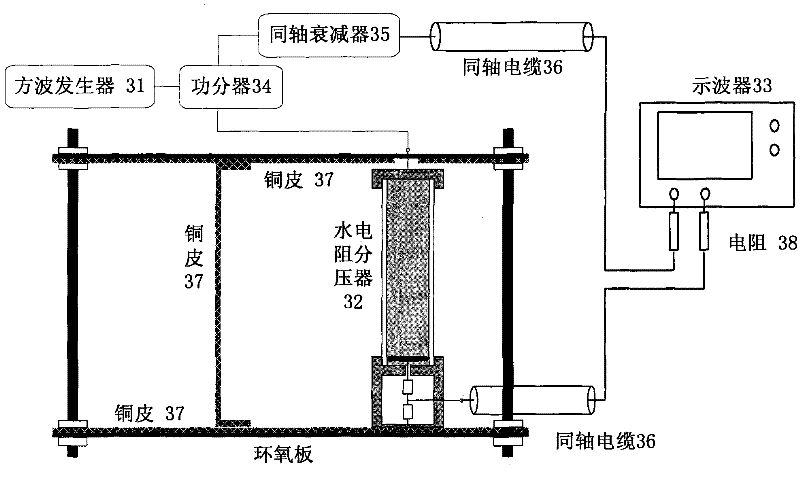

[0022] figure 1 A schematic diagram showing an embodiment of the water resistance divider calibration system of the present invention. in figure 1 (a) shows the schematic diagram of this embodiment calibration system, figure 1 (b) shows a block diagram of the square wave generator of this embodiment. exist figure 1 In (a), the calibration system includes a square wave generator 11 , a water resistor divider 12 and an oscilloscope 13 . Square wave generator 11 produces square wave signal; Square wave signal is divided into two-way signal, is transmitted to water resistance voltage divider 12 and oscilloscope 13 respectively; The water resistor divider 12 is calibrated. exist figure 1 In (b), the square wave generator 11 includes a DC voltage generator 111 , a pulse forming line 112 , a high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com