Patch type RFID (Radio Frequency Identification Device) tire electronic tag device and manufacturing and mounting method thereof

A technology of electronic tags and tires, which is applied in the field of rubber machinery and electronic information, can solve the problems of affecting the reading distance of RFID electronic tags, damage of RFID electronic tags, and irreparable repair and replacement, so as to improve the accuracy rate and the strength of feedback signals, The effect of high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

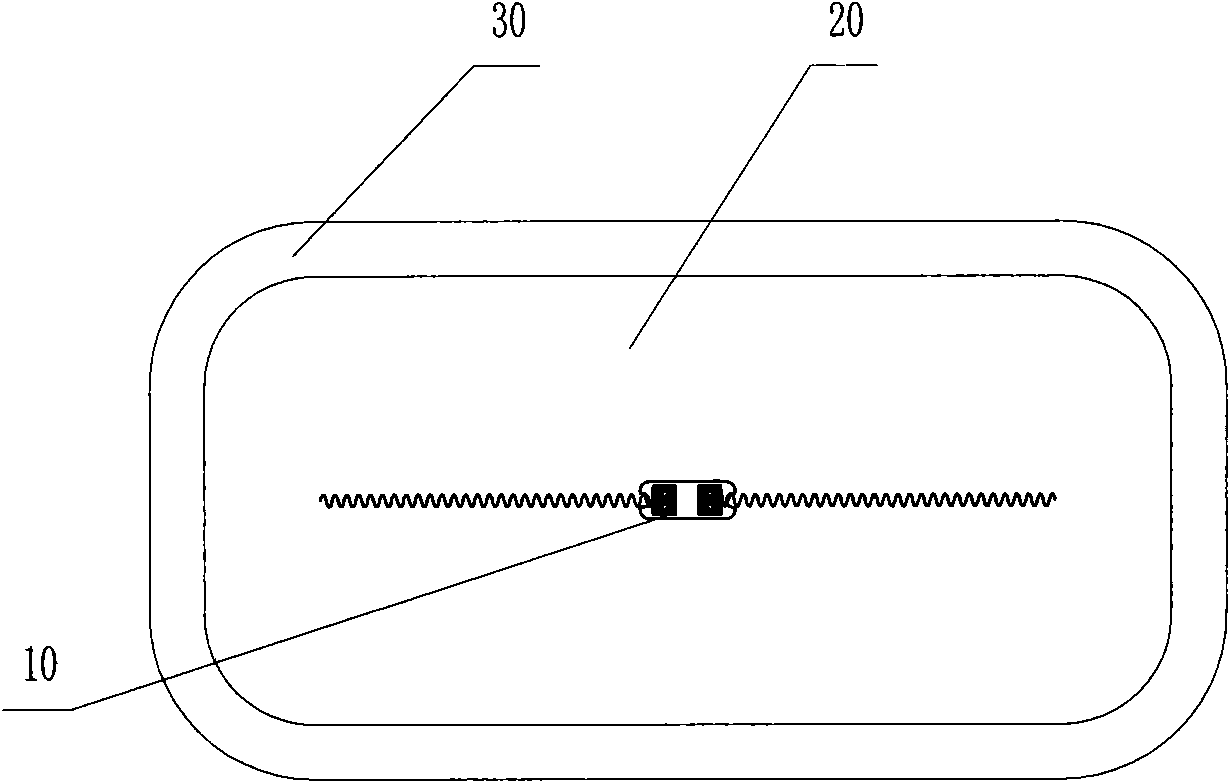

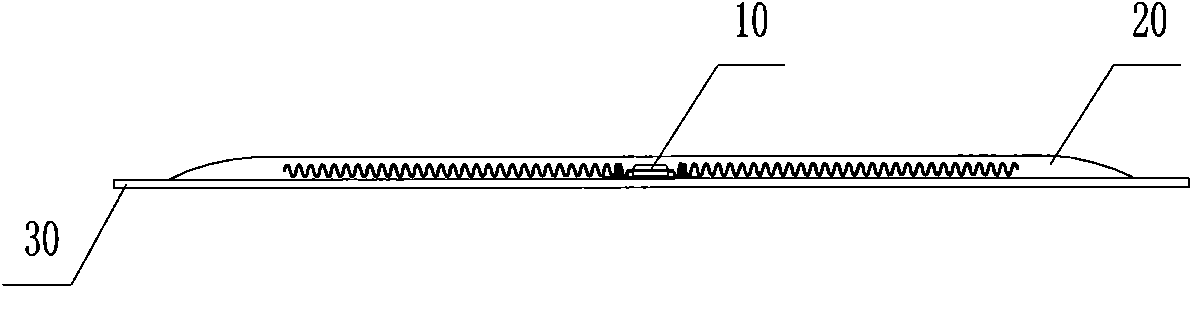

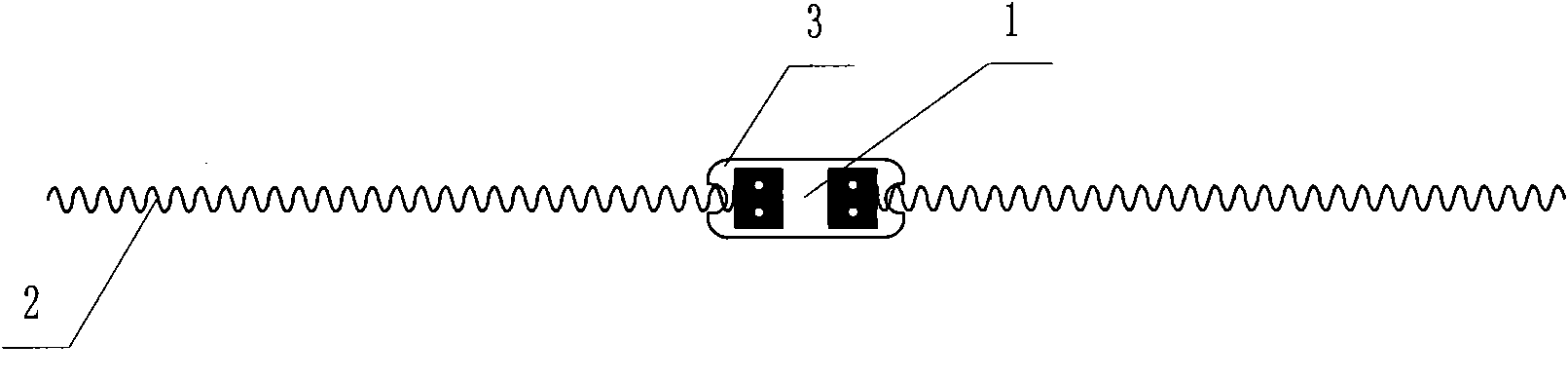

[0031] Example 1, such as Figure 1 to Figure 3 As shown, a patch type RFID tire electronic tag device mainly includes:

[0032] The RFID radio frequency electronic tag 10 is provided with a radio frequency module 1 on the substrate 3, and a group of spring antennas 2 are symmetrically connected to both sides of the radio frequency module 1. The total length of the RFID radio frequency electronic tag 10 is 50-62 mm.

[0033] The RFID radio frequency electronic tag 10 is packaged in a vulcanized film 20 by pressing and vulcanizing, and a gray film 30 is pasted on one side of the vulcanized film 20 .

[0034] Wherein, the area of the vulcanized rubber sheet 20 is smaller than that of the gray rubber sheet 30, and the thickness of the surrounding edges of the vulcanized rubber sheet 20 gradually decreases.

[0035] The patch type RFID tire electronic tag device is oval in shape as a whole, and its total thickness is about 3 mm.

[0036] Gray film 30 has a length of 100 ± 1 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com