High thermal conductivity insulation structure of stator bar of excess epoxy mould pressing insulation system

A technology of insulator and stator, applied in the shape/style/structure of winding insulation, winding insulation materials, etc., can solve the problems of poor electrical performance of insulating materials, low thermal conductivity, unfavorable heat dissipation of wire rods, and inability to apply, etc., to achieve improvement Effects of heat transfer speed, improved thermal conductivity, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

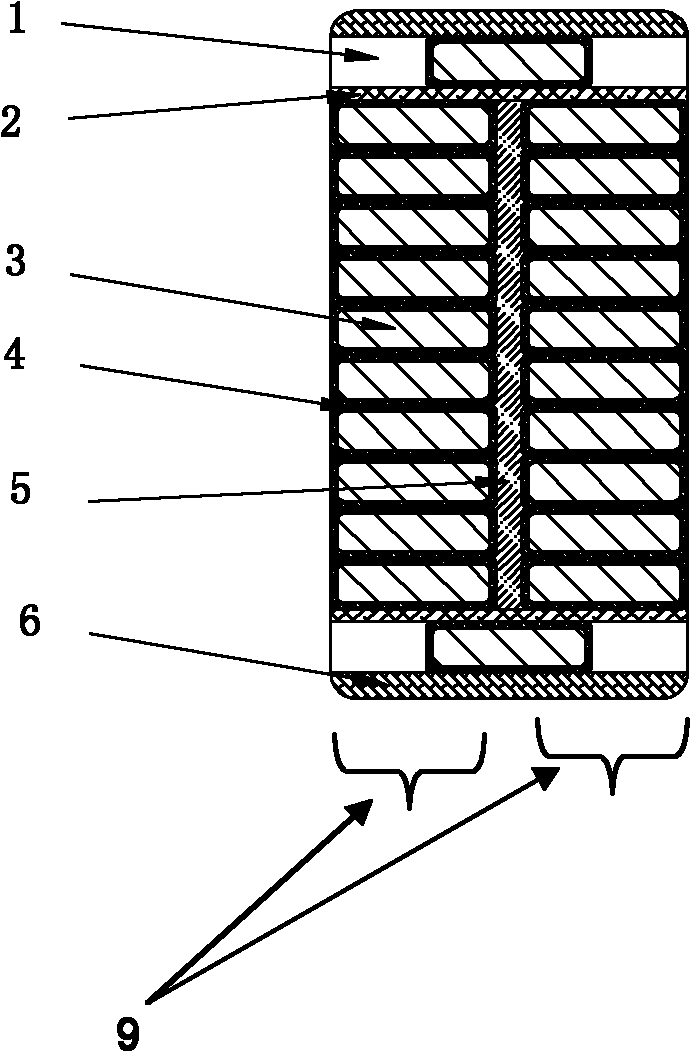

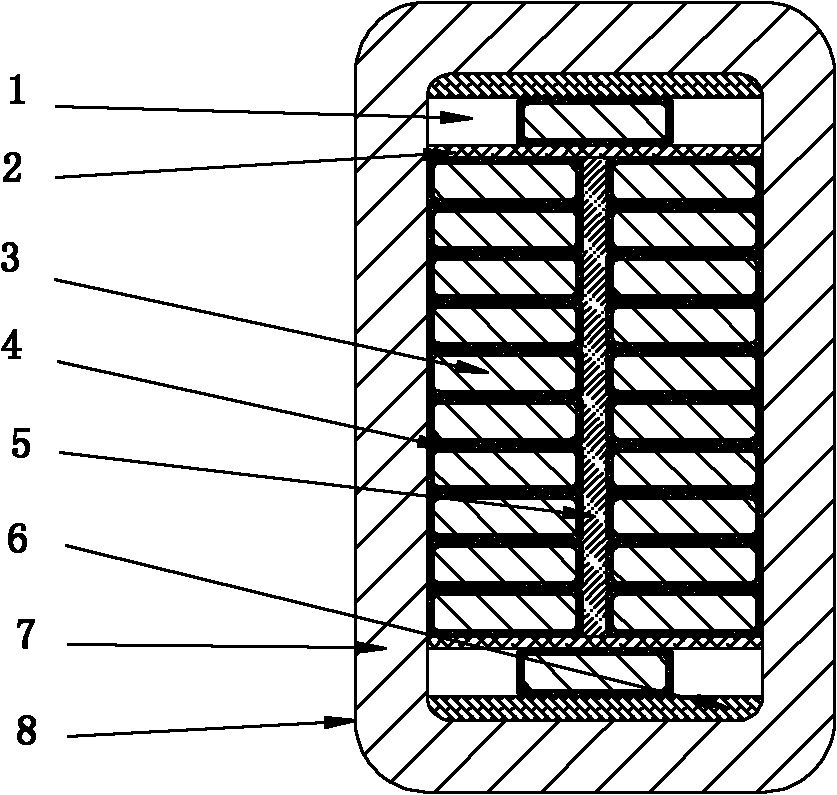

[0013] A multi-glue molded insulation system stator bar with high thermal conductivity insulation structure, the pit 1 of the transposition insulation layer is the insulating material filled between the transposition insulation layer 2 and the narrow surface insulation pad strip 6 of the wire, and the transposition insulation layer 2 is The insulation at the straight line transposition bend of the wire bar prevents the insulation of the electromagnetic wire from being damaged and short-circuited here. The surface insulation layer 4 of the electromagnetic wire and the insulation 5 between the wire rows are located between two rows of wires or multiple rows of wires 9 to avoid electromagnetic wires between rows. Short circuit, wire narrow surface insulating pad strip 6 on the narrow surface of the wire rod, the wire rod main insulation layer 7 is a multi-layer insulation layer surrounding the wire rod, and the anti-corona layer 8 is on the outer layer of the main insulation layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com