Frequency conversion control method and system for circulating water pump motor of thermal power plant

A circulating water pump and frequency conversion control technology, which is applied in the direction of AC motor control, control system, pump control, etc., can solve the problems of not considering the power consumption of the motor, the decrease of the variable load rate of the unit, and disadvantages, so as to reduce the performance index of AGC and improve the regulation Speed, increase the effect of adjusting the power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

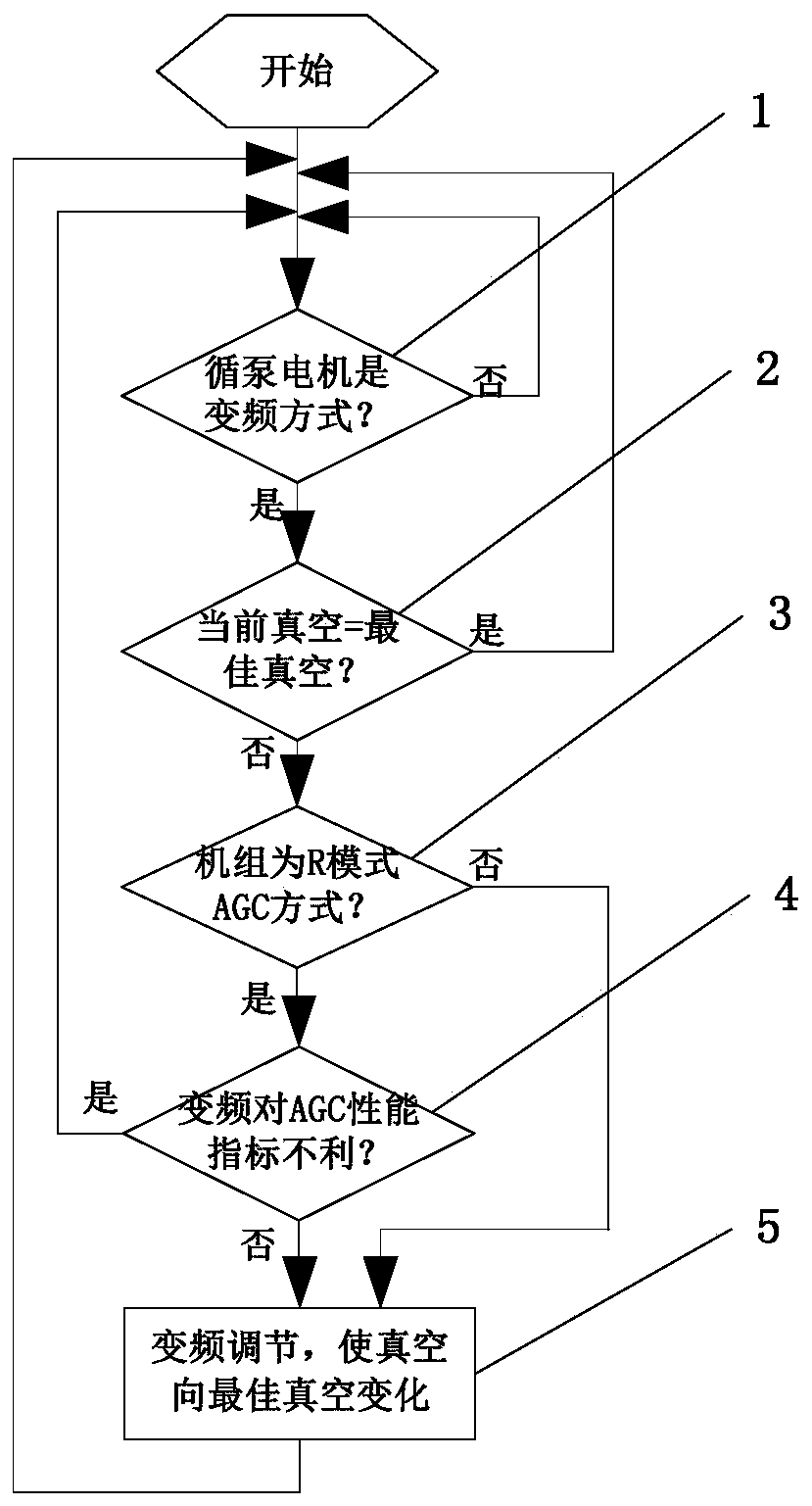

[0033] The purpose of this embodiment is to comprehensively consider the advantages and disadvantages of the existing technology, taking into account energy saving and consumption reduction and improving the AGC performance index of the unit. figure 1 shown, including the following steps:

[0034] Step 1, judge whether the motor of the circulating water pump is in the variable frequency operation mode, if so, execute step 2; otherwise, continue to execute this step.

[0035] This step is the premise of the frequency conversion control of the circulating water pump motor, that is, the following steps are necessary only when the circulating water pump motor is in the frequency conversion operation mode.

[0036] Step 2, judge whether the vacuum value of the condenser is the optimum vacuum value, if so, return to step 1; otherwise, execute step 3.

[0037]Regarding the optimal vacuum value of the condenser, there are many introductions in existing technologies and literatures, t...

Embodiment 2

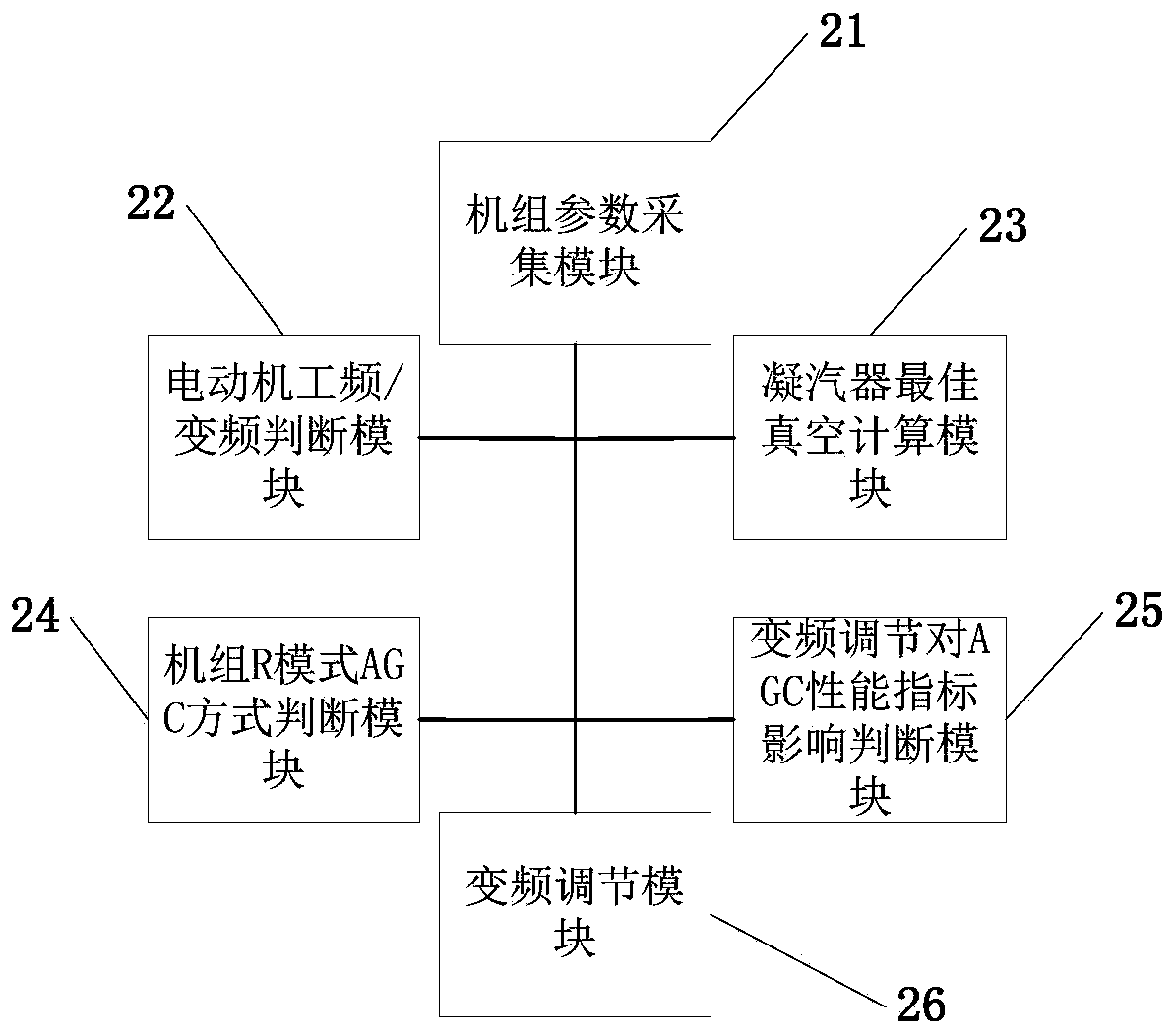

[0059] The purpose of this embodiment is to provide a thermal power plant circulating water pump motor frequency conversion control system, such as figure 2 As shown, the control system includes 6 modules, which are: 21. Unit parameter acquisition module; 22. Motor power frequency / frequency conversion judgment module; 23. Condenser optimal vacuum calculation module; 24. Unit R mode AGC mode Judgment module; 25. Judgment module of influence of frequency conversion adjustment on AGC performance index; 26. Frequency conversion adjustment module.

[0060] The unit parameter acquisition module is used to collect the operating parameters of the unit and the circulating water pump, such as condenser vacuum, atmospheric pressure, thermal power unit active power, circulating water pump motor power, etc., for use by other modules.

[0061] The electric motor power frequency / variable frequency judging module is used to judge whether the circulating water pump motor is in power frequency...

Embodiment 3

[0073] The purpose of this embodiment is to provide an electronic device.

[0074] In order to achieve the above object, this embodiment provides an electronic device, including a memory, a processor, and a computer program stored on the memory and operable on the processor. When the processor executes the program, the following steps are implemented, including :

[0075] Step 1, judge whether the motor of the circulating water pump is in the variable frequency operation mode, if so, execute step 2; otherwise, continue to execute this step.

[0076] Step 2, judge whether the vacuum value of the condenser is the optimum vacuum value, if so, return to step 1; otherwise, execute step 3.

[0077] Step 3, judge whether the unit is running in the AGC mode that unconditionally undertakes to adjust the power, or judge whether the unit is in the AGC mode and runs in the R mode: if yes, go to step 4, otherwise go to step 5.

[0078] Step 4, judging whether changing the power supply fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com