Integrative ship engine room monitoring system

A monitoring system and engine room technology, applied in transmission systems, electrical components, etc., can solve problems such as single diagnostic object, difficulty in establishing a ship key equipment prediction and health management system, and failure to realize the integration of condition monitoring control and fault diagnosis. The effect of high economy and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

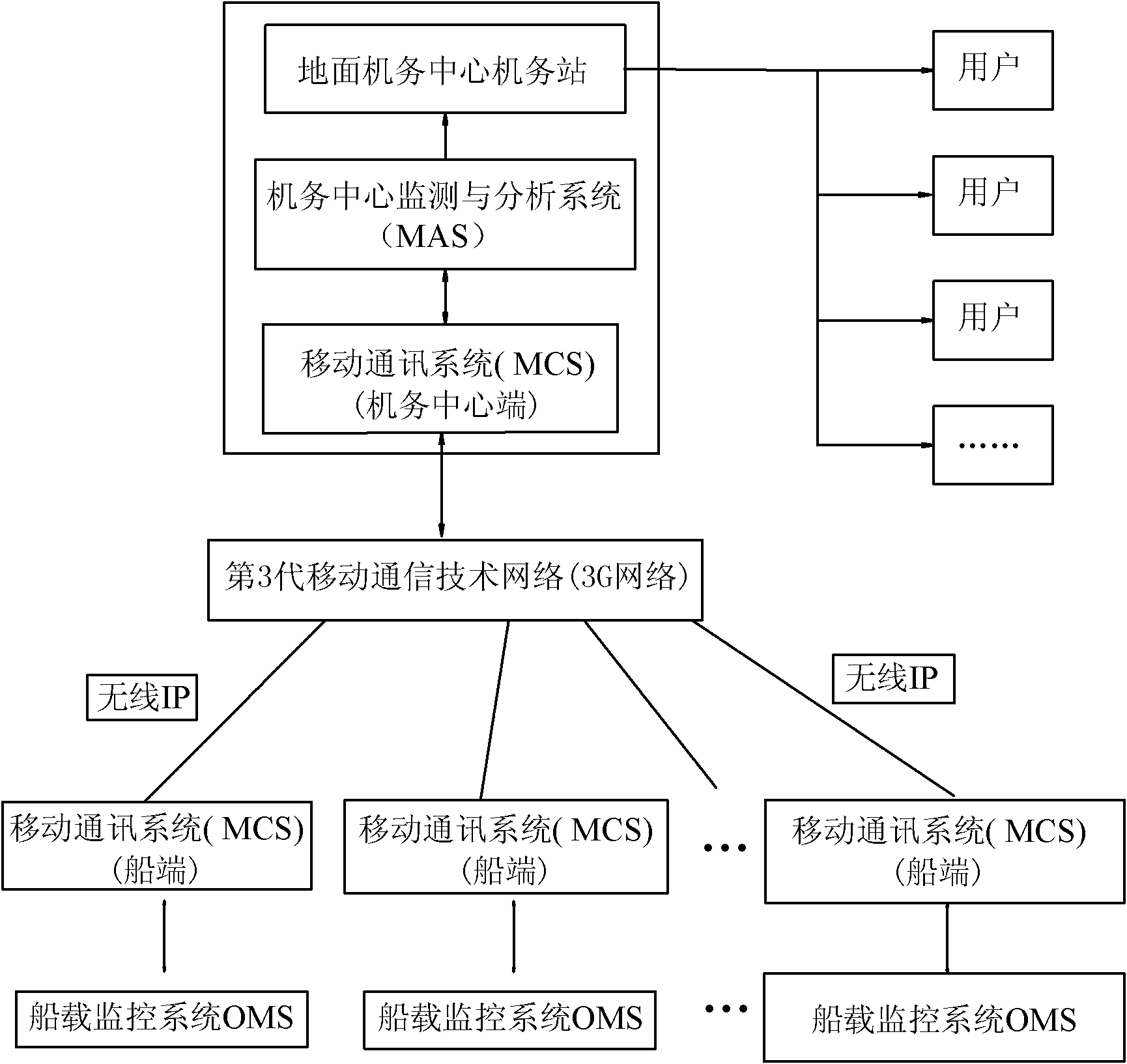

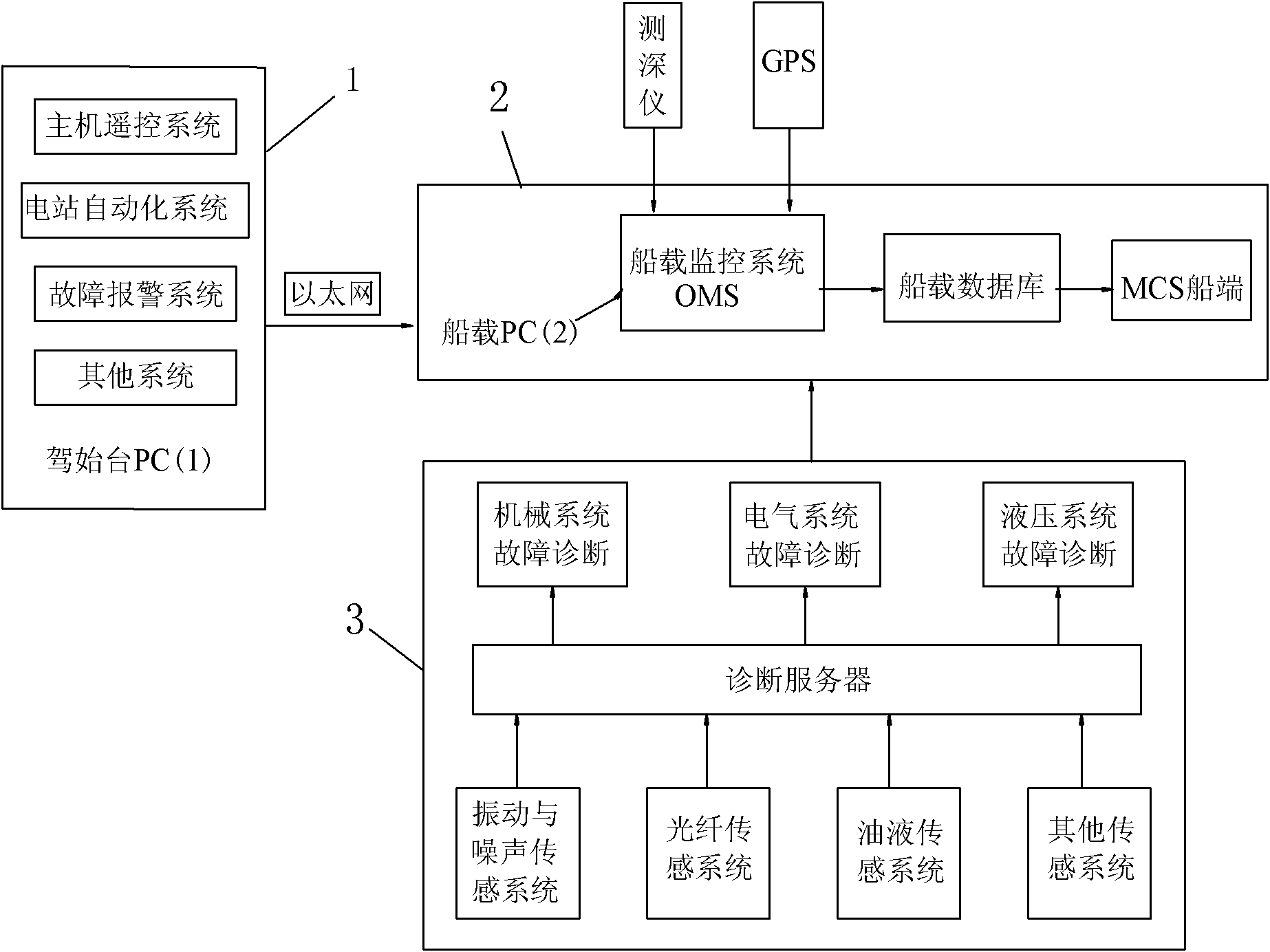

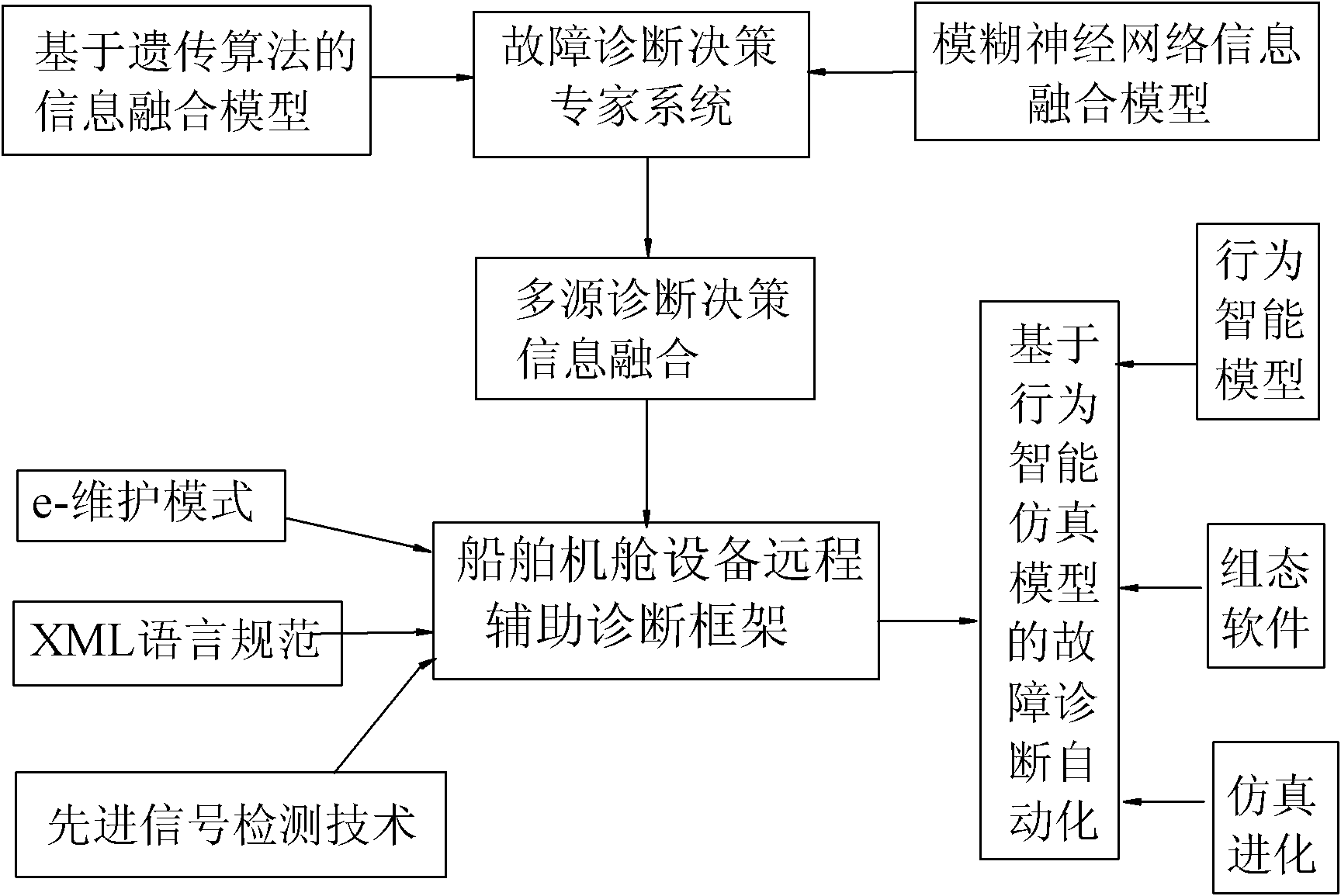

[0030] The invention designs a comprehensive and integrated ship engine room monitoring system. The system integrates the engine room automation system, multi-object-oriented fault intelligent diagnosis system, optimized maintenance decision-making system, and ship-to-shore wireless communication system, thereby building a PHM / CBM system for ship equipment. In addition to operation, it also has the capabilities of fault detection, fault isolation, enhanced diagnosis, performance detection, fault prediction, health management, component life tracking and other capabilities for various equipment, and it is cross-linked with the autonomous security system through the wireless communication system to achieve reduction Business goals such as downtime, optimized spare parts storage, balanced scope of work, and reduced cost of ownership.

[0031] In order to better understand the present invention, the present invention will be further described below in conjunction with the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com