Shell and manufacturing method thereof

A manufacturing method and shell technology, which can be applied to electrical equipment shells/cabinets/drawers, decorative arts, electrical components, etc., can solve the problems of single paint layer appearance and affect product appearance, and achieve the purpose of increasing added value, beautiful appearance, and appearance colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

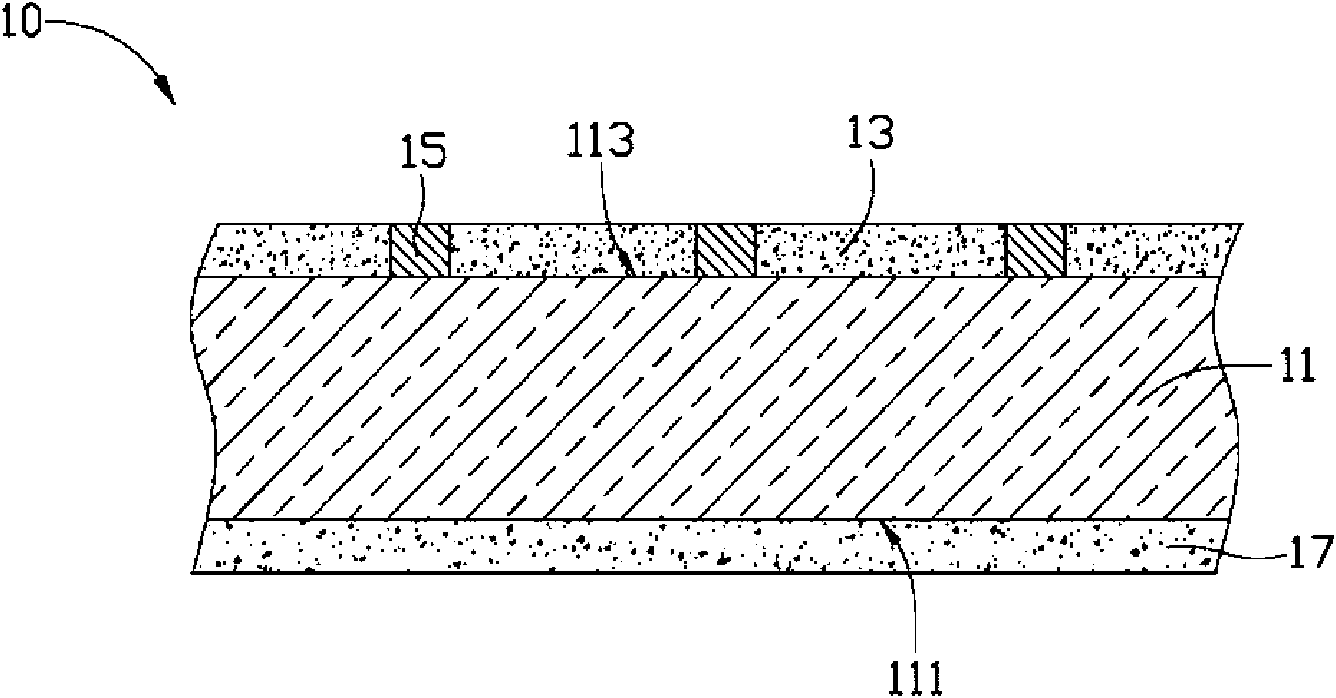

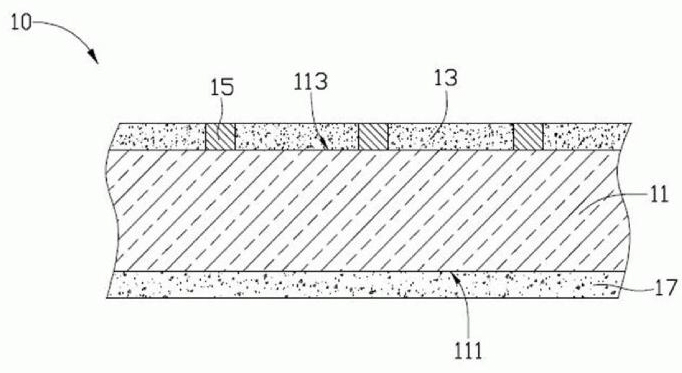

[0012] see figure 1 As shown, the housing 10 of a preferred embodiment of the present invention includes a transparent substrate 11, a baking varnish layer 13 and a metal film layer 15 formed on one surface of the transparent substrate 11, and a protection layer formed on the other surface of the transparent substrate 11. Layer 17.

[0013] The transparent base 11 can be a plastic layer, which is made by injection molding. Plastics for injection molding the transparent substrate 11 can be selected from transparent polypropylene (PP), polyamide (PA), polycarbonate (PC), polyethylene terephthalate (PET) and polymethyl methacrylate (PMMA) in any one. The transparent substrate 11 can also be a glass layer. The transparent substrate 11 includes an outer surface 111 and an inner surface 113 opposite to the outer surface 111 .

[0014] The baking varnish layer 13 is formed on a partial area of the inner surface 113 of the transparent substrate 11 by spraying paint. The baking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com