Coiled material coating of velvet flash crystal face decorative plate special for aluminum plate coiled material and preparation method thereof

A technology of coil coating and coil material, applied in the direction of polyester coating, coating, etc., can solve the problems of poor hand feeling, high pollution, high production cost, etc., and achieve the effect of reducing production cost and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

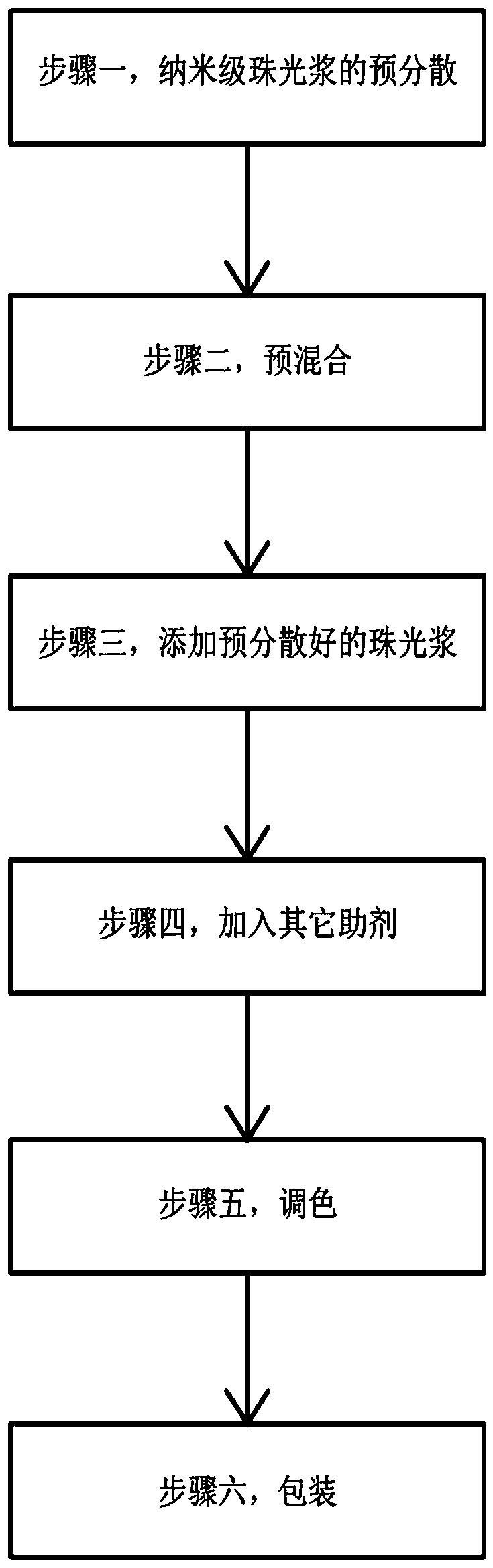

Method used

Image

Examples

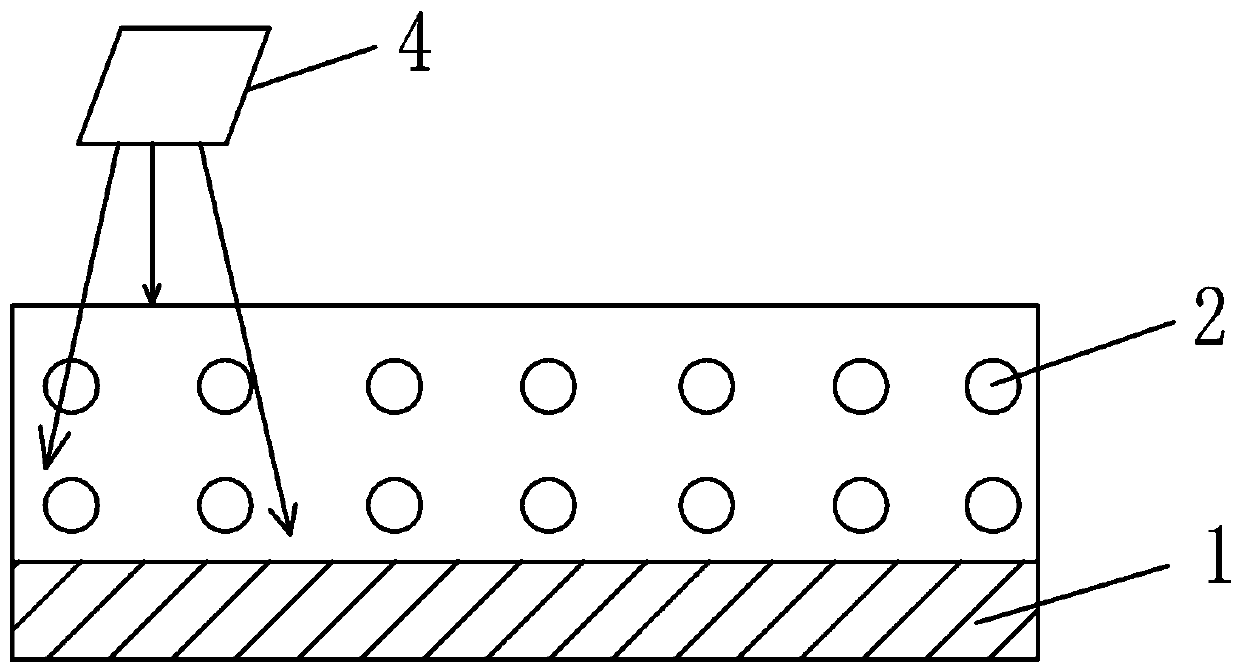

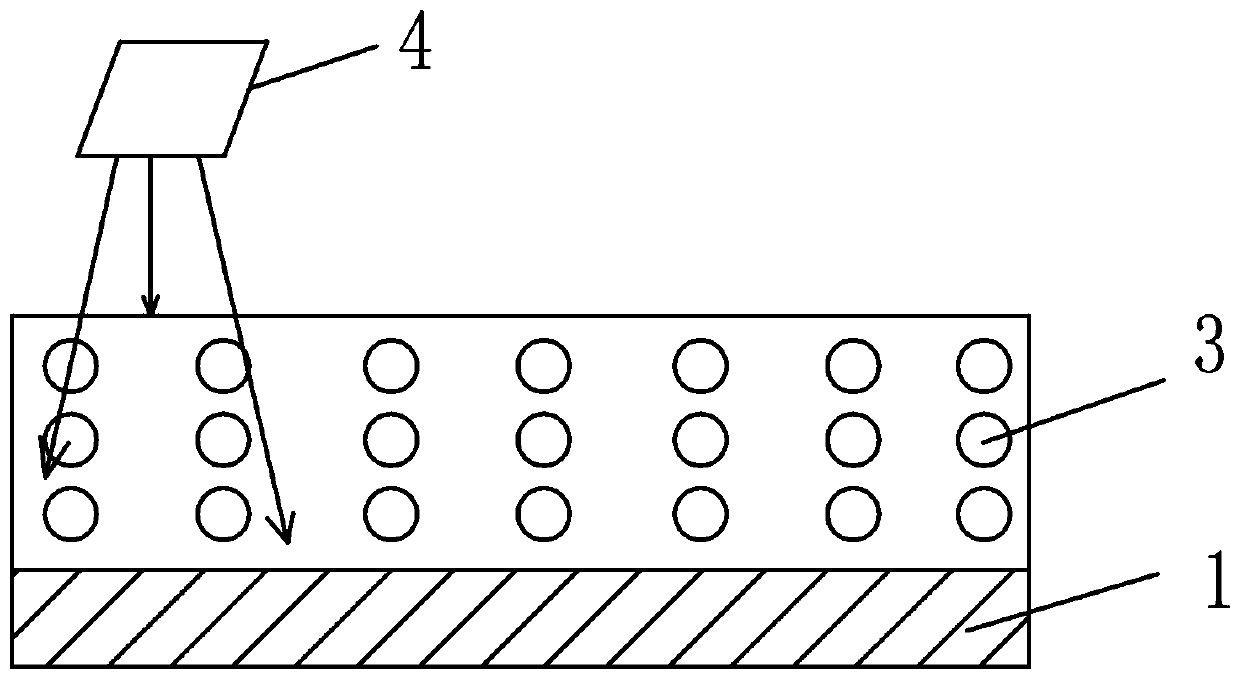

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiment:

[0039] A coil coating for velvet sparkling surface veneer specially used for aluminum coils, characterized in that it includes the following components and their weight percentages: environmentally friendly solvent: 5-10%; dispersant: 0.5-1%; catalyst: 0.5% -1%; Amino 5-10%; Defoaming agent: 0.3-0.5%; Adhesive agent: 0.5%-1.0%; Leveling agent: 0.3-3%; : 0.5-1%; nano-scale pearlescent paste: 10-20%; polyester resin 50-70%; silane oligomer powder: 3%-6%.

[0040] As a more specific solution, the environmentally friendly solvent includes three or four of n-butanol, DBE, butyl ester and ethylene glycol monobutyl ether. The dispersant includes one or both of polyurethane copolymer and amide compound. The catalyst contains one or both of dodecylbenzenesulfonic acid and isonew acid. The defoamer is a fluorine-containing foam-breaking polymer solution, and the adhesive is a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com