HIPS (High Impact Polystyrene) composite board

A composite sheet and composite film layer technology, which is applied in the field of surface decorative sheets and sheets, can solve the problems of heavy glass material and complicated process, and achieve the effects of reducing quality, simplifying the production process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

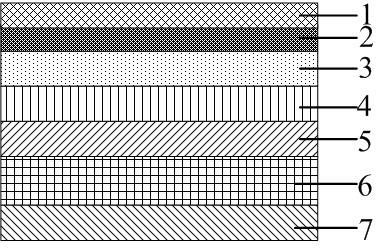

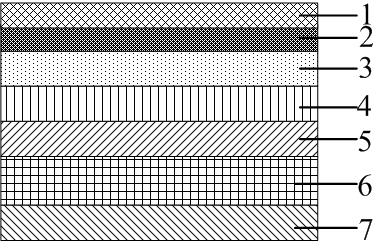

[0017] Such as figure 1 As shown, for the HIPS composite board, the front side of the PET transparent film layer 2 is sprayed with UV coating 1. The UV coating 1 has the characteristics of improved surface hardness, scratch resistance, good weather resistance, and good transparency. The thickness of the PET transparent film layer 2 The bottom surface of PET transparent film layer 2 is formed with screen printing layer 3 by screen printing, and the bottom surface of PET transparent film layer is processed by screen printing. Trademarks, personalized patterns, etc. can be printed according to customer requirements, which can fully The three-dimensional sense of the composite board can be fully reflected, and the diversified and individual needs of customers can be better met. The bottom surface of the screen printing layer 3 is coated with the first adhesive layer 4, and the first adhesive layer 4 is bonded to the PET / PVC composite film layer. 5. The bottom surface of the PET / PV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com