Scalable cell culture bioreactor and cell culture process

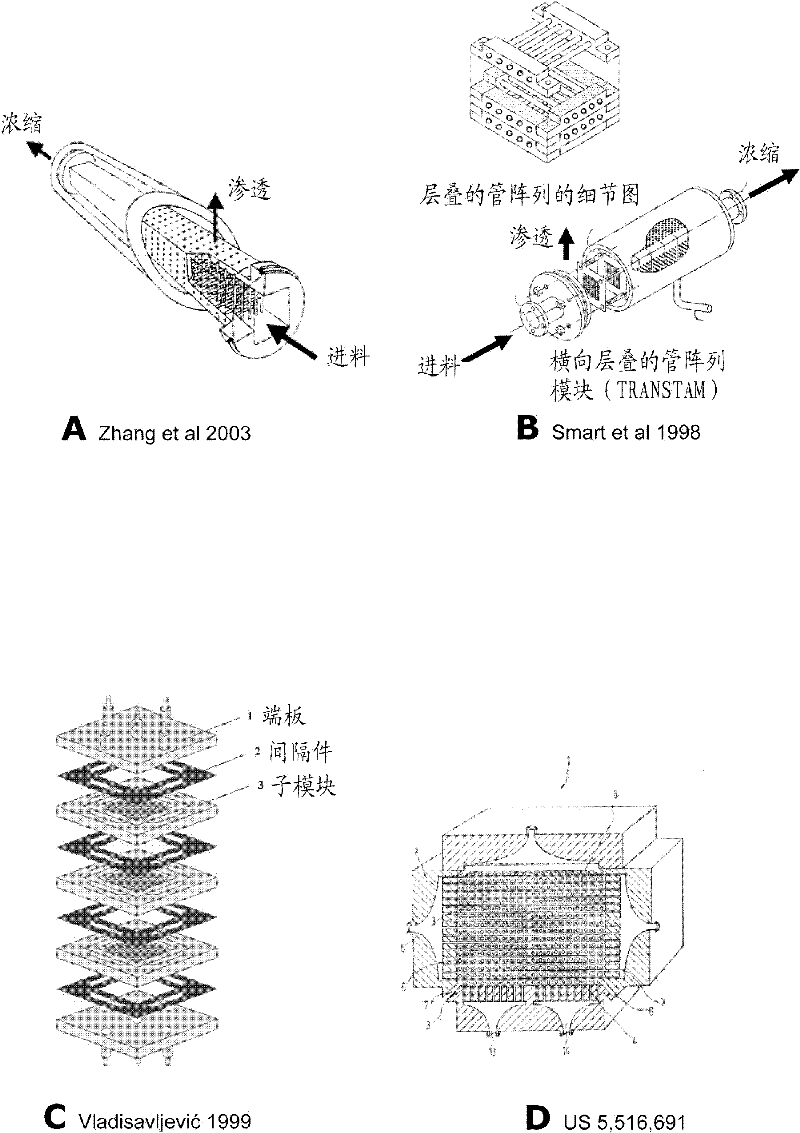

A bioreactor, scaling technology, applied in biochemical equipment and methods, methods of supporting/immobilizing microorganisms, methods of sterilization, etc., can solve problems such as limiting the scale of HFR design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

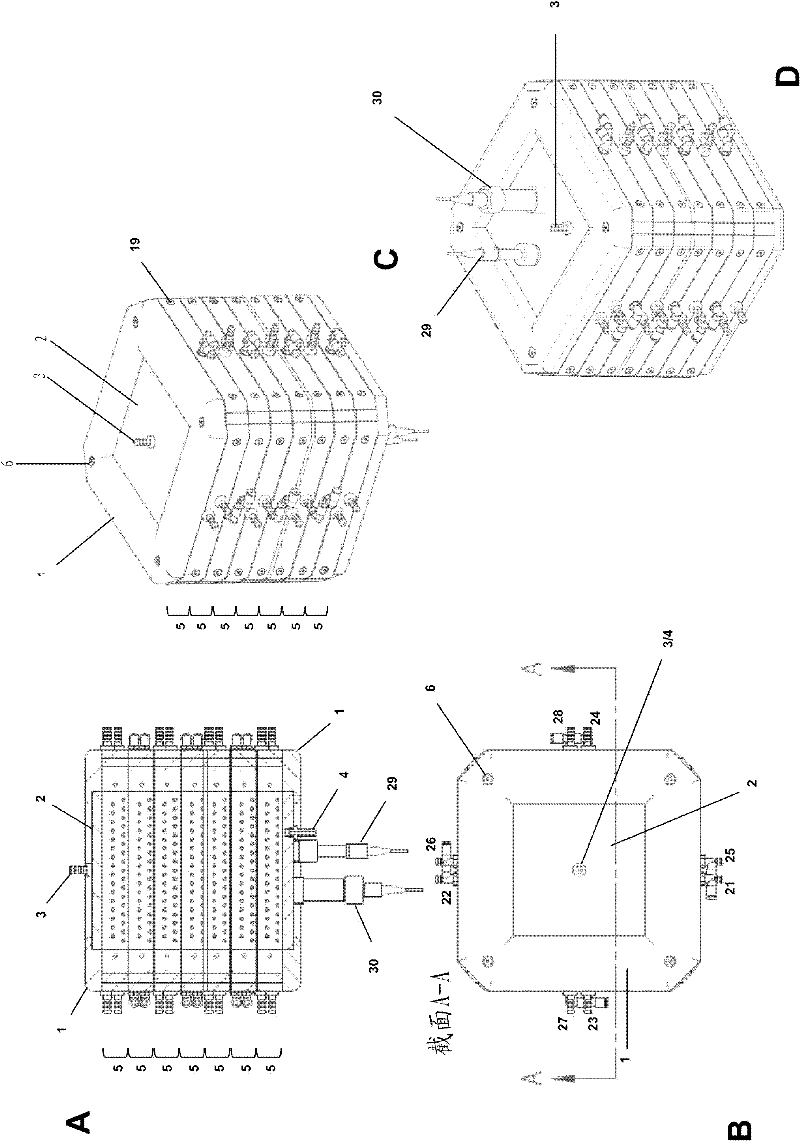

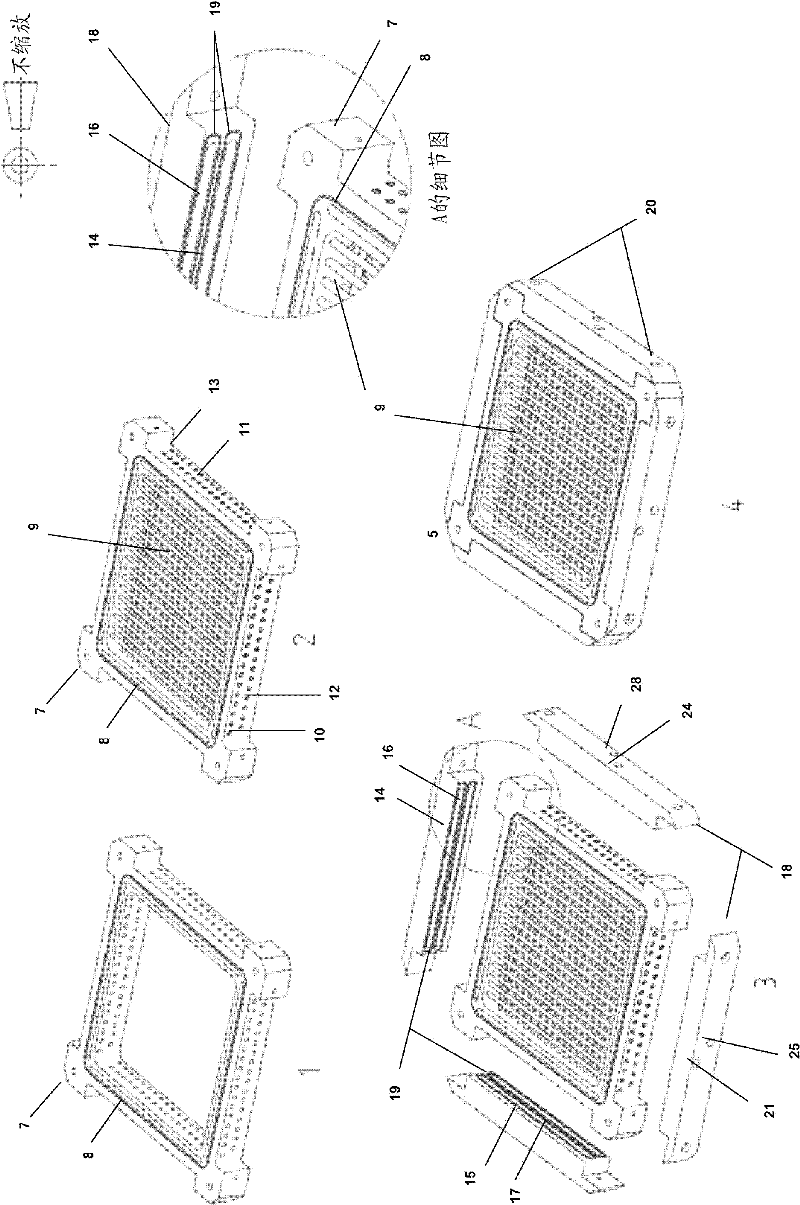

[0053] In this design, the principle of modular augmentation and processing flexibility is incorporated into the 2-D and 3-D designs of capillary network membranes. Scalable membrane bioreactor equipment ( figure 2 and 3 ) includes 2 top plates (1) and at least 1 box body (5) fixed between the 2 top plates, effectively defining the extracapillary space (ECS), and separating it from the inner capillary space (ICS) located in the hollow fiber membrane )differentiate. figure 2 The complete cell culture module is shown showing 2 top plates (1 ) holding eg 7 individual cassettes (5). The upper and / or lower top panels may include a central transparent viewing panel (2) which allows viewing of the interior of the module during operation. Each top plate may also include at least 1 ECS hole (3, 4), which functions as an inlet / outlet to the ECS; and at least 1 fitting or hole, which allows passage of, for example, a pH fitting (29) or a DO probe (30) Insert the probe or sensor int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com