Short thermal profile oven useful for screen printing

A technology of convective heat and radiant heat, used in electrical components, conveyor objects, transportation and packaging, etc., which can solve the problems of low absorption rate, long processing time, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

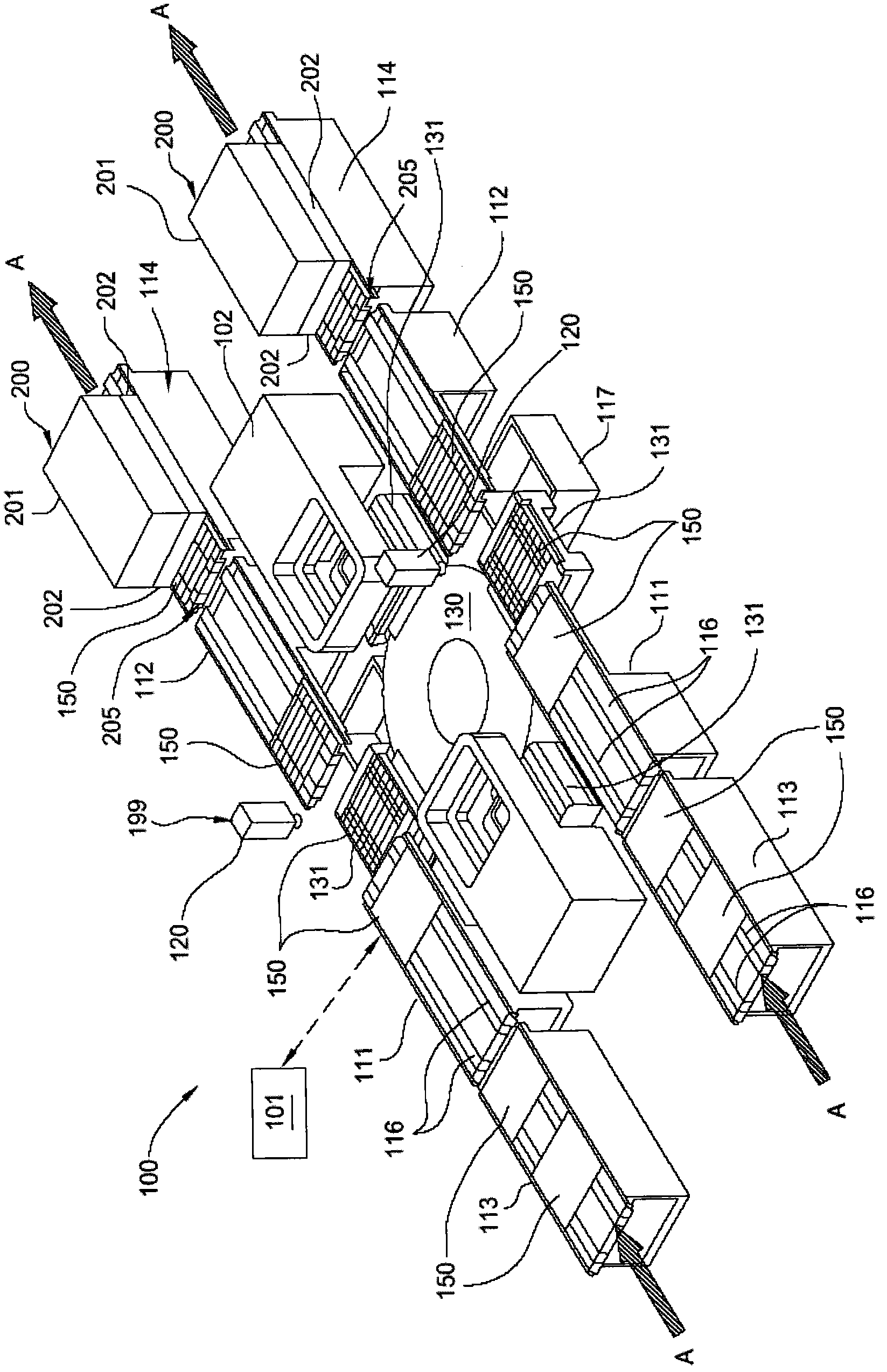

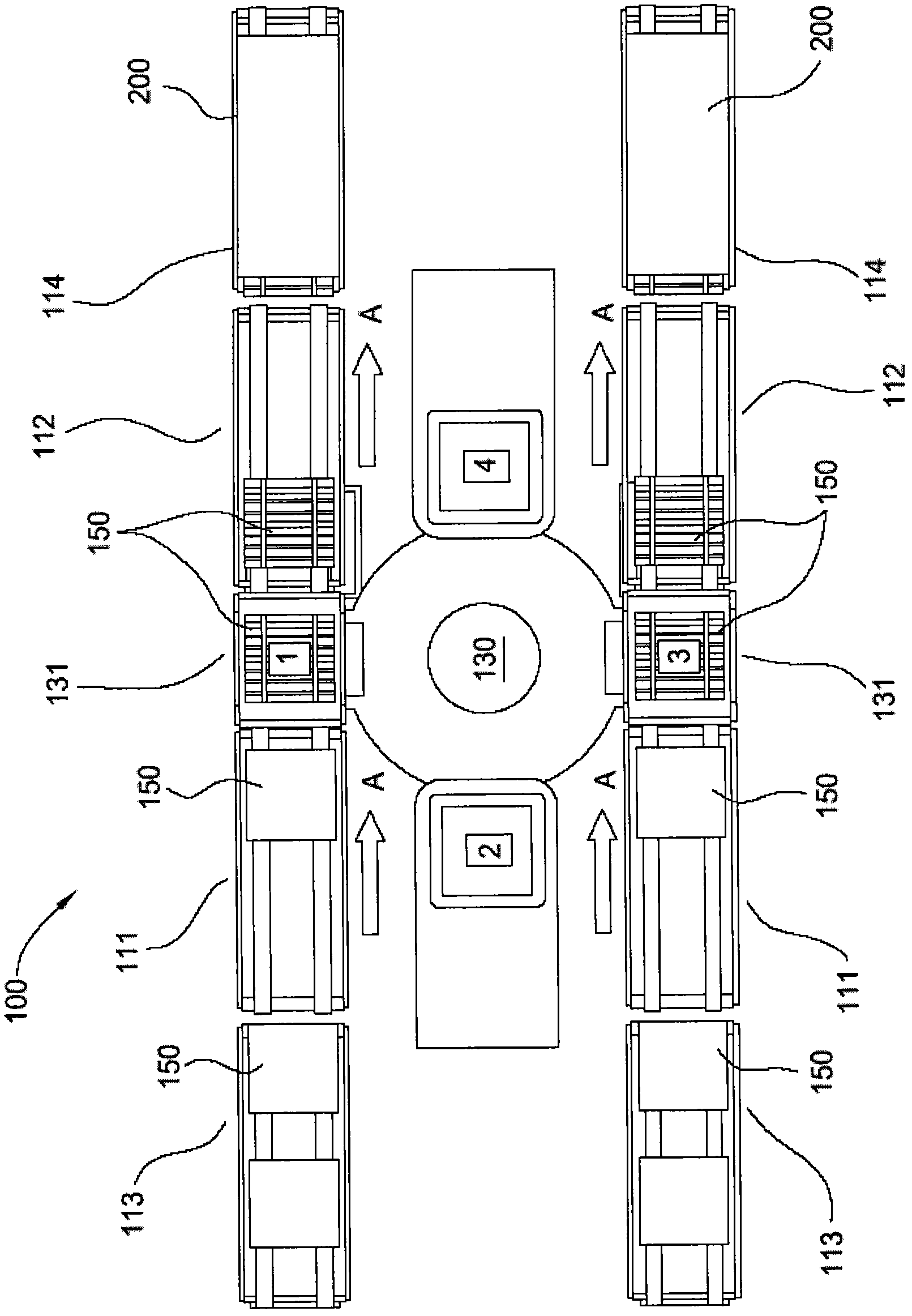

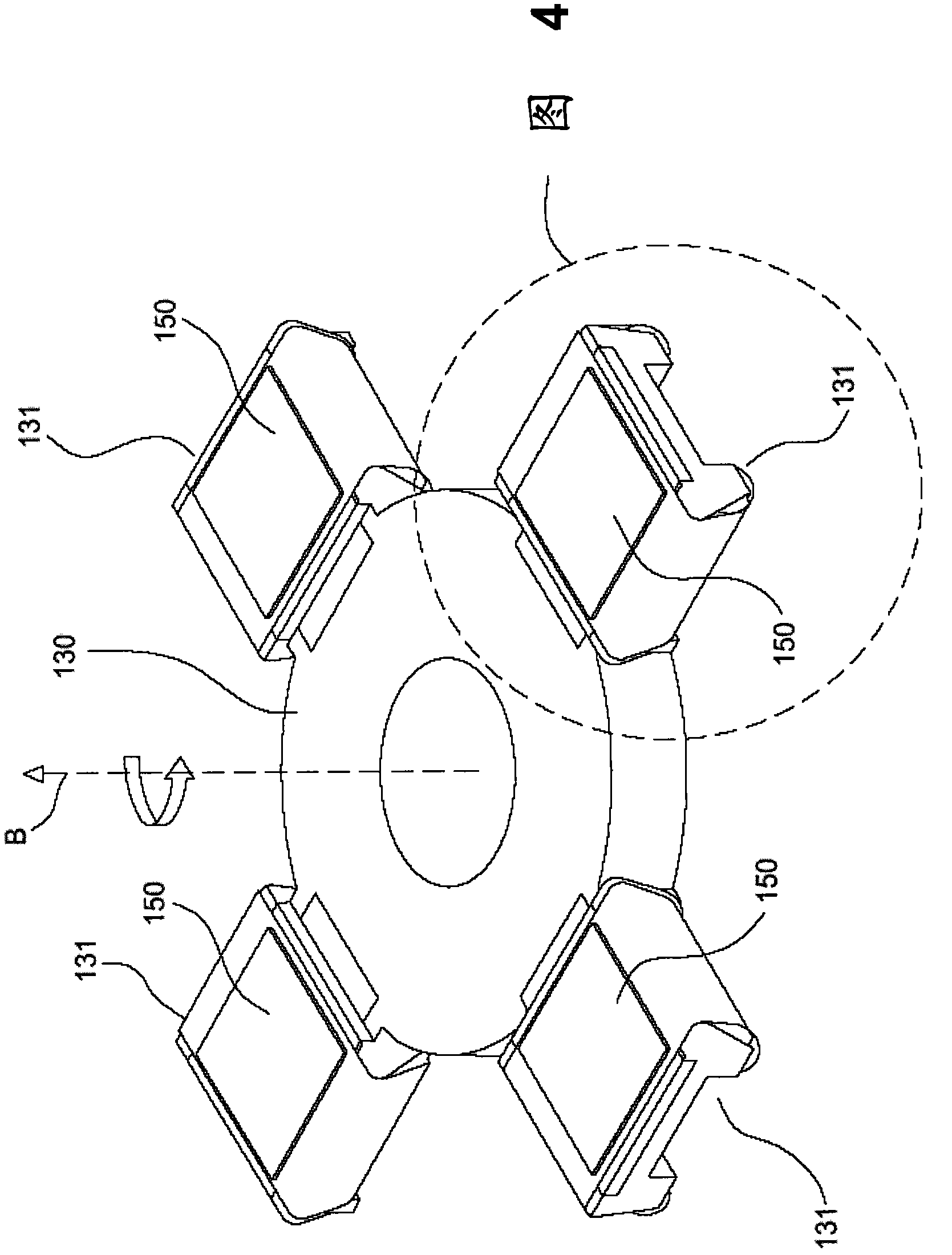

[0024] The present invention proposes an apparatus and method for effectively drying deposited material on a substrate surface. The apparatus and methods described herein are useful for removing solventborne materials of deposited materials on a substrate surface. In some cases, the material can be deposited by a screen printing process. In one embodiment, the screen printing chamber is adapted to deposit a patterned material on a crystalline silicon substrate, followed by drying the deposited material in a drying chamber. In one embodiment, both the screen printing chamber and the drying chamber are located on a rotary line tool or Softline from Baccini S.p.A. TM Within the tool, the Baccini S.p.A. is owned by Applied Materials, Inc. of Santa Clara, California, USA.

[0025] screen printing system

[0026] Figure 1 to Figure 2 A multiple screen printing chamber processing system, or system 100, is shown that may be used with various embodiments of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com