Piston supercharged material steam explosion method and device

A material and steam explosion technology, which is applied in the field of steam explosion devices, can solve the problems in the field of waste stabilization treatment that is difficult to apply, the steam explosion temperature and pressure cannot be controlled separately, and the application range of steam explosion technology can be reduced, so as to enrich the types of energy utilization , Overcoming incomplete unloading of materials, reducing energy consumption and economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A piston pressurized material steam explosion method, the steps are as follows:

[0026] Step 1: Feed the material into the tank from the feed port of the tank, and inject steam explosion gas into the tank after closing the feed port,

[0027] Step 2 When the material is heated to the steam explosion temperature, push the pressurized piston in the tank to compress the material, so that the tank can be boosted to the steam explosion pressure,

[0028] Step 3 Quickly release the pressure to make the material expand, burst and discharge,

[0029] In this embodiment, the discharge in step 3 is by pushing the booster piston, so that the pulverized material is discharged from the discharge port.

Embodiment 2

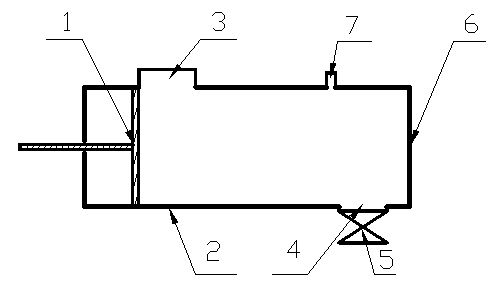

[0031] A device for implementing the above piston pressurized material steam explosion method, comprising a tank body 2, a steam inlet 7, a feed port 3 and a discharge port 4 on the tank body 2, and a steam inlet 7 and a discharge port 4 respectively A valve is provided, and a booster piston 1 is arranged in the tank body 2 , the feed port 3 is adjacent to the booster piston 1 at the starting position, and the valve at the discharge port 4 is a quick-open valve 5 .

Embodiment 3

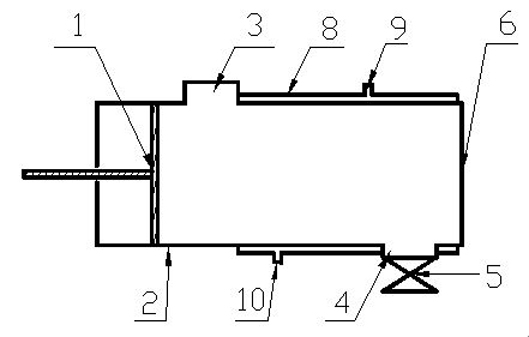

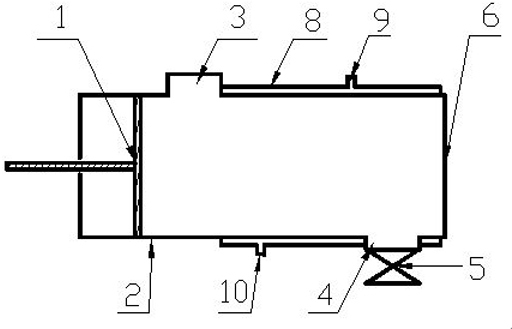

[0033] Another device for implementing the above-mentioned piston pressurized material steam explosion method, comprising a tank body 2, a booster piston 1 is arranged in the tank body 2, and a gap between the initial position of the booster piston 1 and the closed end 6 of the tank body A heating jacket 8, a feed port 3 and a discharge port 4 are arranged on the tank body, a heating medium inlet 9 and a heating medium outlet 10 are provided on the heating jacket 8, and a heating medium inlet 9, a heating medium outlet 10 and a discharge port 4 are respectively provided with valves, the feed port 3 is adjacent to the booster piston 1 at the initial position, and the valve at the discharge port 4 is a quick-open valve 5. In this embodiment, the material is heated indirectly .

[0034] Below with reference to accompanying drawing, the present invention is described in more detail:

[0035] refer to figure 1 , a piston pressurized steam explosion device, which includes a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com