Shower head

A technology of shower head and curved surface, which is applied in the field of shower head to achieve the effect of easy processing and manufacturing, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

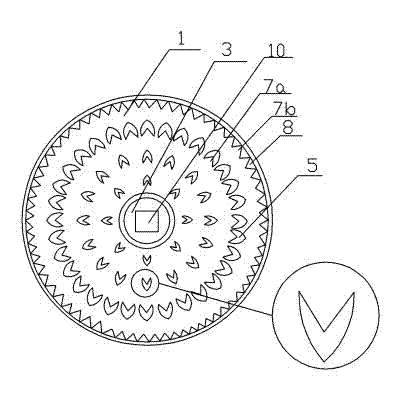

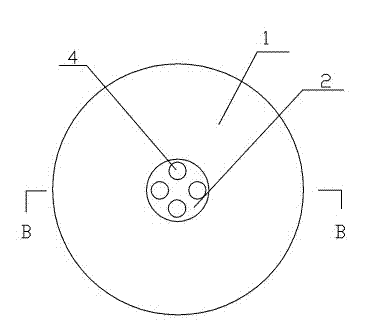

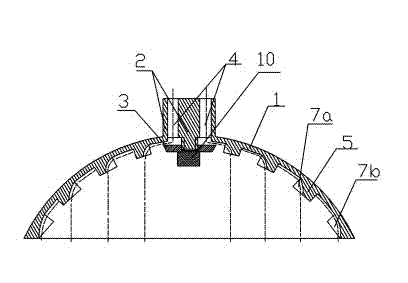

[0027] see figure 1 , figure 2 , image 3 , the shower head includes a water spray cover 1 on the surface of the ball table shell, a water inlet pipe joint 2 and 4 circular water inlets 4 distributed on the water inlet pipe joint, wherein the center of the inner surface of the water spray cover 1 is threaded with the water inlet pipe joint 2 Together, the inverted truncated cone water flow guides the dispersing mechanism 3, the diameter of the upper end face circle of the inverted truncated cone is greater than the diameter of the circle below the water inlet pipe joint 2 in the center of the curved surface water spray cover 1, and the water spray cover 1 around the water flow guide dispersing mechanism 3 The inner surface is provided with approximately V-shaped and approximately inverted V-shaped dripping protrusions 5 from the inside to the outside. The dripping protrusions 5 and the curved water spray cover are molded at one time. The inner surface of the drip guiding pro...

Embodiment 2

[0029] see Figure 6 , Figure 7 , Figure 8 , the shower head includes a truncated cone shell surface water spray cover 1, a water inlet pipe joint 2 and three circular fan-shaped water inlets 4 distributed on the water inlet pipe joint, wherein the center of the inner surface of the water spray cover 1 has threads with the water inlet pipe joint 2 The truncated cone water flow guiding dispersing mechanism 3 that is connected together with the angle of the truncated cone surface water spray cover is matched. The inner surface of the spray cover 1 around the guide dispersion mechanism 3 is provided with approximately V-shaped and approximately inverted V-shaped drip projections 5 from the inside to the outside, and the inner and outer surfaces of the drip guide projections are arc-shaped surfaces; the drip projections The approximately V-shaped or approximately inverted V-shaped opening on the 5 forms a sprinkler opening 7a, and the distribution of the dripping protrusion 5 ...

Embodiment 3

[0031] see Figure 4 , Figure 5 , the shower head includes a parabolic shell spray cover 1 with a cut-off opening downward, a water inlet pipe joint 2 and two water inlets 4 distributed on the water inlet joint, wherein the center of the inner surface of the water spray cover 1 has threads with the water inlet joint 2 The short cylinders connected together lead to the dispersing mechanism 3, the cross-sectional diameter of the short cylinder is greater than the diameter of the circle below the water inlet pipe joint 2 in the center of the curved surface spray cover 1, and the inner surface of the spray cover 1 around the water flow guiding dispersing mechanism 3 Radial curved water-retaining guide strips 6 are provided from the inside to the outside, and the water-retaining guide strips 6 and the water spray cover are molded at one time. Arc water retaining guide bar 6 inboards have serrated water spout 9, and arc water retaining guide bar 6 has six, has 14 serrated water sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com