Installing and regulating method and device of parabolic antenna sample plate

A parabolic antenna, installation and adjustment technology, applied to antennas, measuring devices, instruments, etc., can solve the problems of poor generality of gaskets, high labor intensity, low work efficiency, etc., and achieve the effects of easy implementation, reduced labor intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

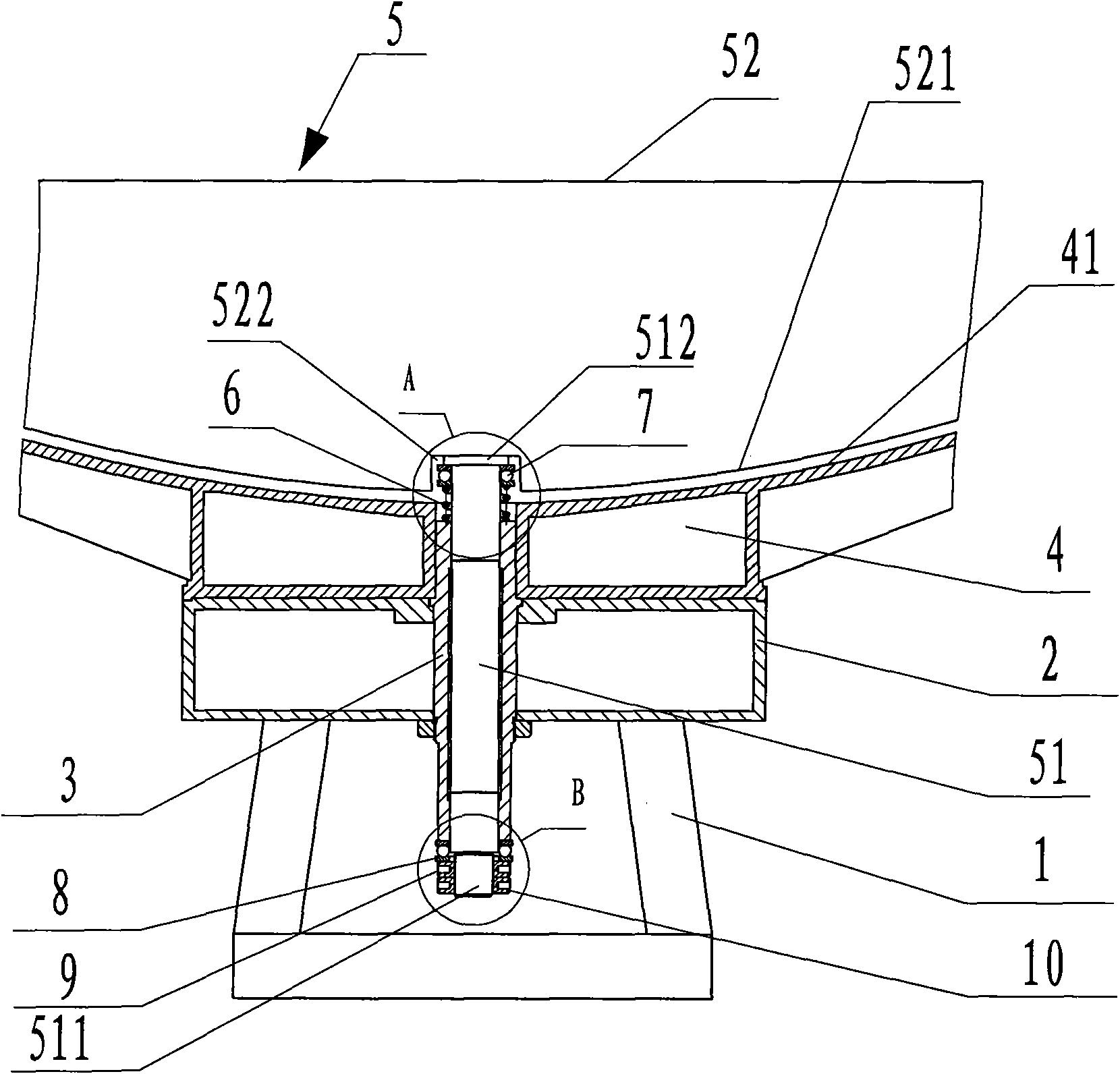

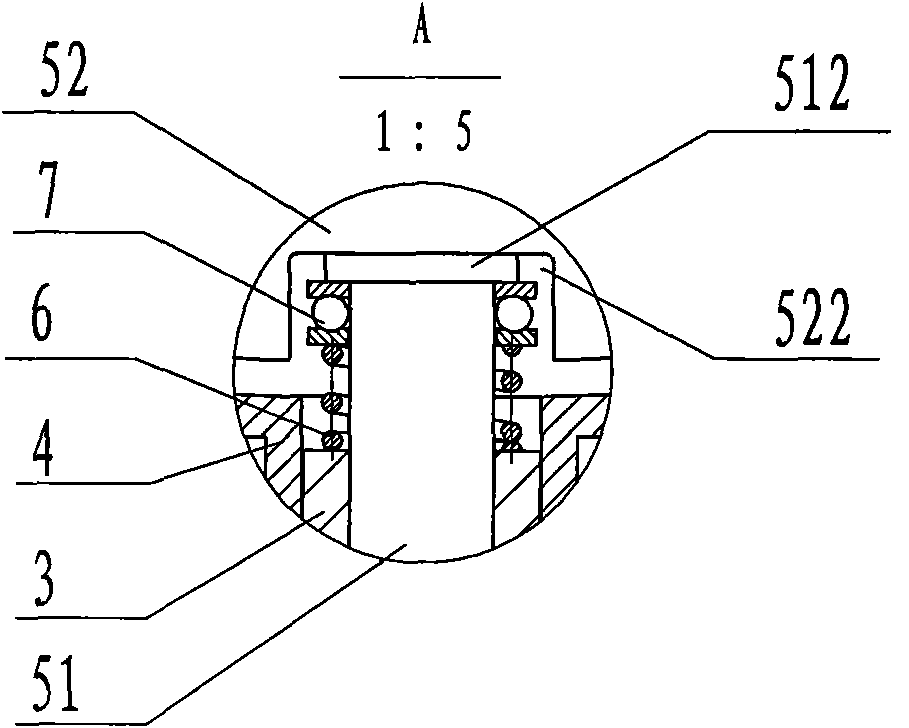

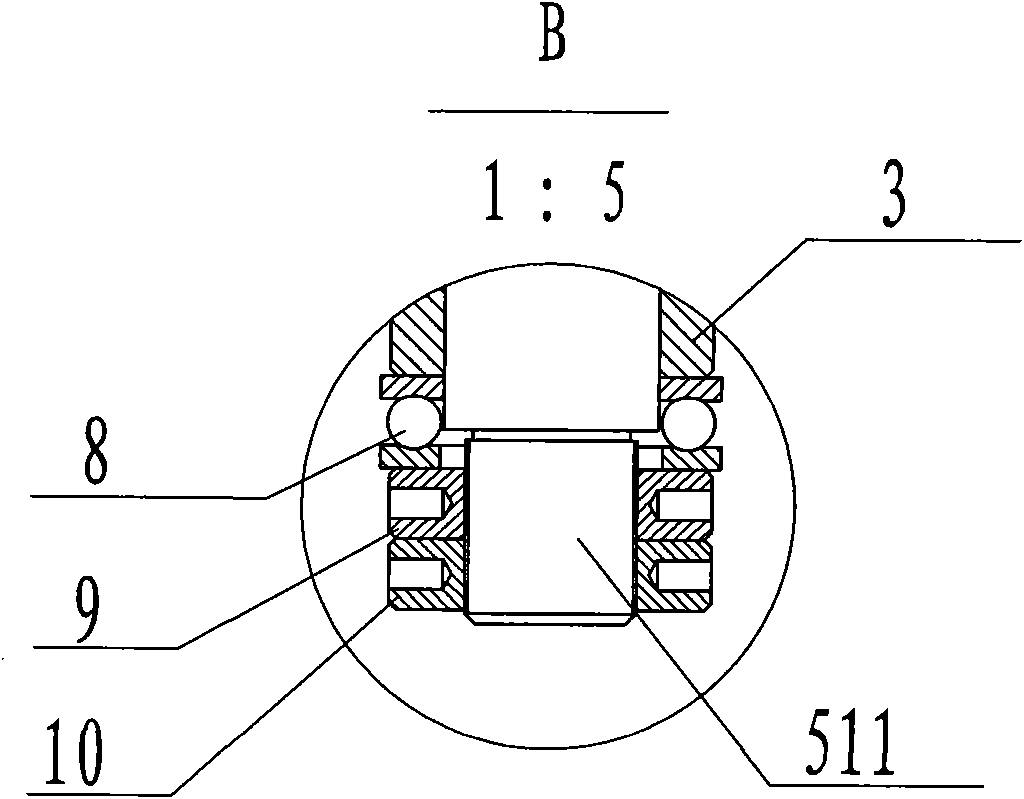

[0030] see figure 1 , figure 2 , image 3, the installation and adjustment device of the parabolic antenna model, which is characterized in that the support 1 is provided with a workbench 2, the antenna base 4 is placed on the workbench 2, and the end of the hollow shaft 3 located in the center of the workbench 2 protrudes from the workbench 2, the antenna base 4 provided with the antenna reflection surface 41 is placed on the workbench 2, and the hollow shaft 3 is inserted in the cylindrical cavity at the center of the antenna base 4; the cylindrical cavity and the antenna reflection surface 41 coaxial, the axis of the hollow shaft 3 coincides with the axis of the cylindrical cavity, that is, the axis of the hollow shaft 3 coincides with the axis of the antenna reflection surface 41; the parabolic template 5 includes a template axis 51 and a template provided with a detection surface 521 The body 52 and the sample shaft 51 are inserted into the hollow shaft 3. The spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com