Air suction/exhaust method and structure of V-shaped box type facial tissue folding machine

A folding machine and paper extraction technology, applied in the direction of folding thin materials, thin material processing, transportation and packaging, etc., can solve problems such as cost increase, waste, restrict production efficiency, etc., to reduce equipment manufacturing costs, reduce equipment operating costs, The effect of increasing the suction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] For further setting forth the present invention, the present invention is described in detail below in conjunction with accompanying drawing and preferred embodiment:

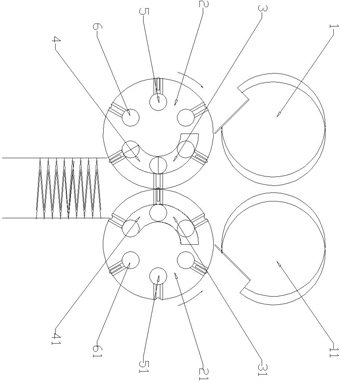

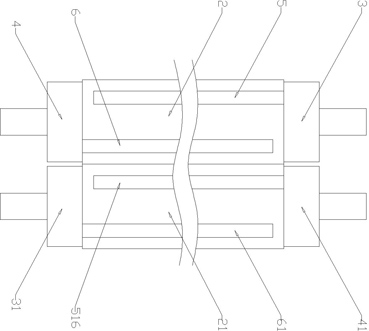

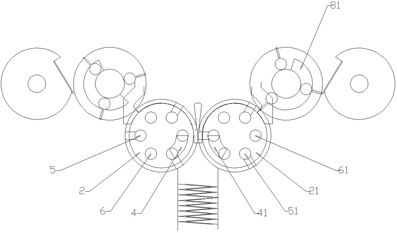

[0037] Such as Figure 4 - Figure 5 As shown, the suction and deflation structure of a V-shaped box pumping paper towel folding machine of the present invention includes two left folding rollers 2 and right folding rollers 21 arranged side by side on the horizontal plane to cooperate with rotation, and two folding rollers arranged side by side on the upper part of the folding rollers. Cutter shaft, its cutter shaft is arranged horizontally and cooperates with the upper left cutter shaft 1 and the upper right cutter shaft 11 of rotating paper cutting, the upper left cutter shaft 1 and the upper right cutter shaft 11 are located above the folding paper roller 2 (21) and are connected with the folding paper roller 2 (21) ) to cooperate with rotation; origami roller 2 (21) roll surface is respectively prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com