Method for synthesizing high-dispersibility high-specific surface area large-pore volume SiO2 hollow spheres

A technology with a high specific surface area and a synthetic method, applied in the field of microporous/mesoporous molecular sieve materials, can solve the problems of serious agglomeration, easy environmental pollution, and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

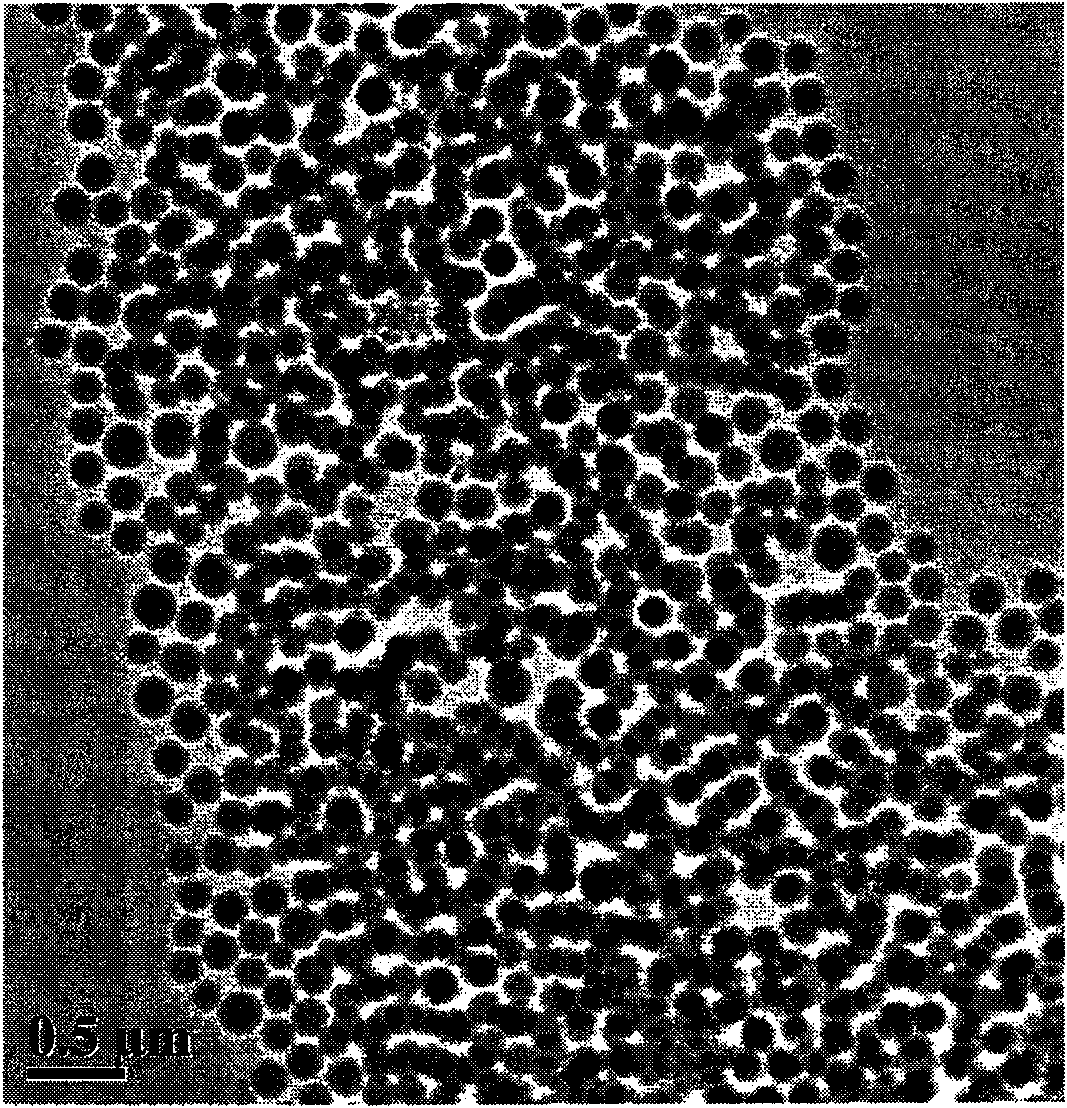

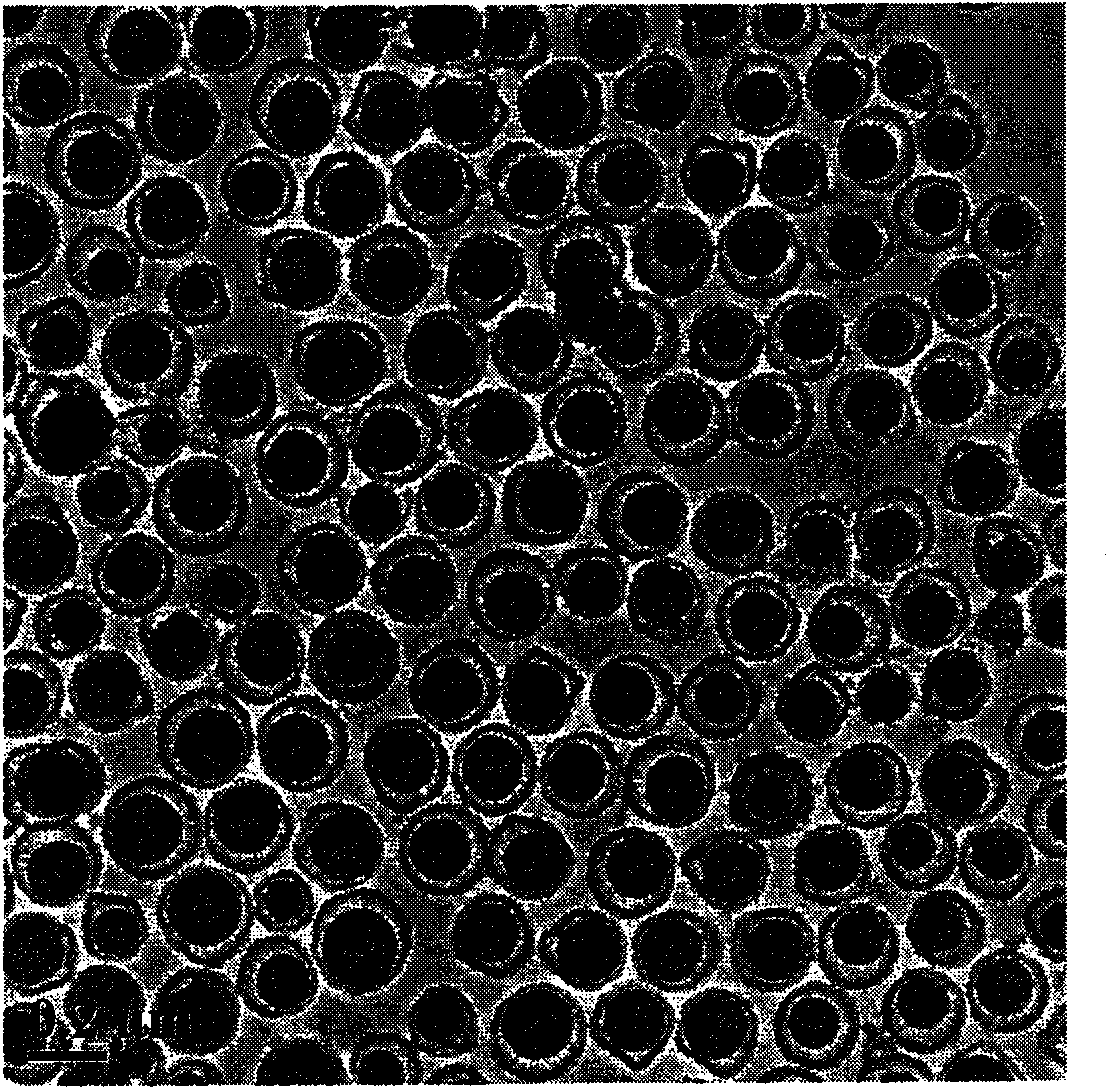

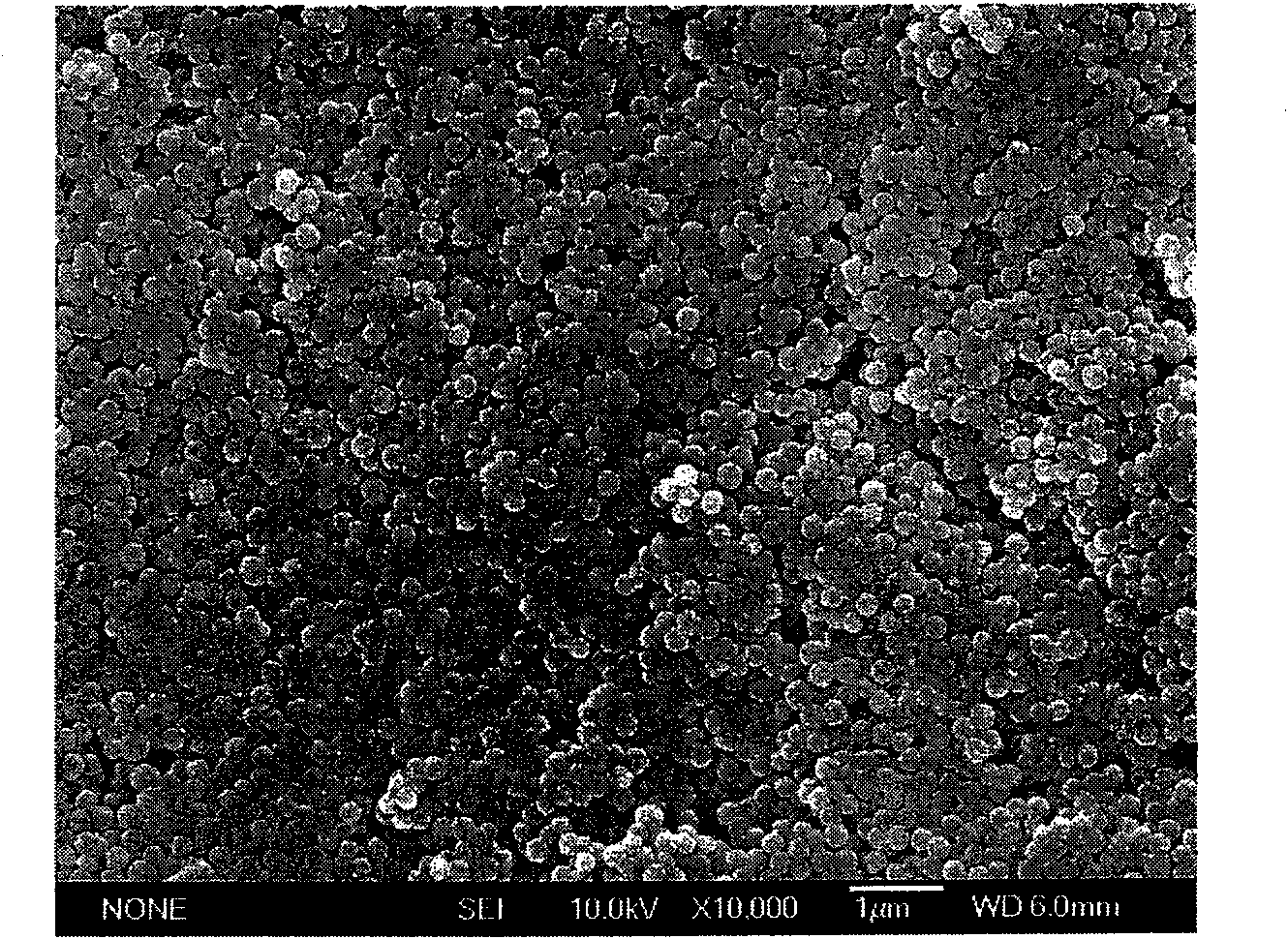

[0017] Mix 71.4mL of absolute ethanol, 10mL of deionized water and 3.14mL of ammonia water, stir at 30°C for 30min; quickly add 6mL of ethyl orthosilicate, and magnetically stir for 1h; After the alkyltrimethoxysilane is uniformly mixed, the above solution is quickly added, and magnetically stirred for 1 h, and the product is centrifuged to obtain highly dispersed solid core / mesoporous shell SiO 2 nanospheres. The centrifuged product was dispersed in 0.12mol / L ammonia solution and heated at 150°C for 24h. After centrifugation, the product was washed three times with deionized water, dried at 100°C for 6h, and then calcined at 550°C for 6h to remove the surfactant.

Embodiment 2

[0027]According to the synthesis process of Example 1, the solid core / mesoporous shell SiO is first obtained 2 nanospheres. After centrifugation, the product was dispersed in 0.12mol / L ammonia solution and heated at 180°C for 24h. Subsequent processing was as in Example 1.

Embodiment 3

[0031] According to the synthesis process of Example 1, the solid core / mesoporous shell SiO is first obtained 2 nanospheres. After centrifugation, the product was dispersed in 0.05mol / L ammonia solution and heated at 150°C for 72h. Subsequent processing was as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com