Trussed sludge circulation clarifying pool

A technology of clarifier tanks and truss trucks, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, settling tanks, etc., can solve problems such as high water source pressure requirements, complex pool structure, and large water head. Achieve enhanced mud-water separation effect, simple pool structure, and high-quality treated water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

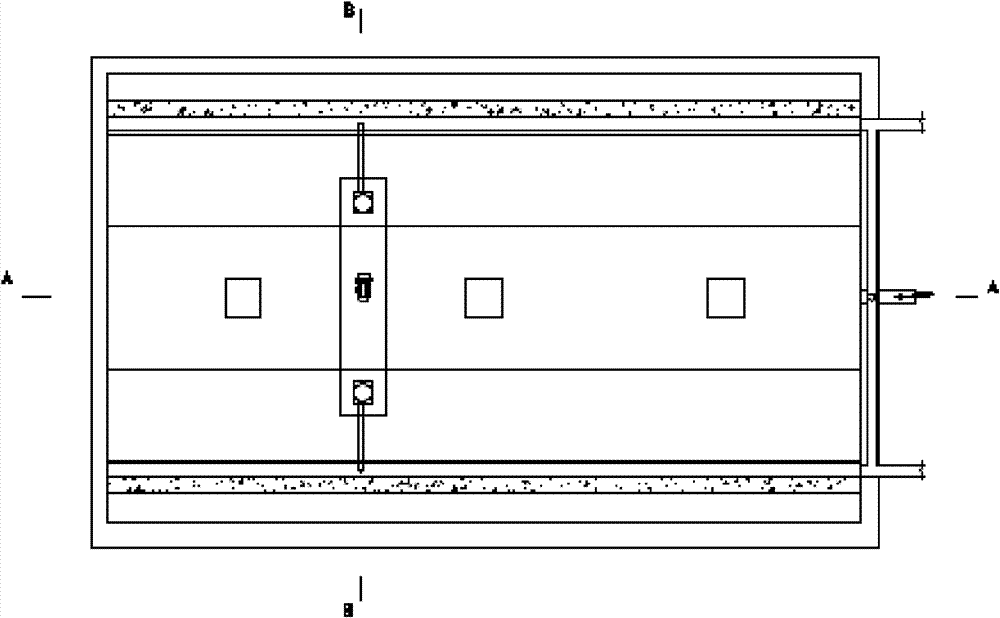

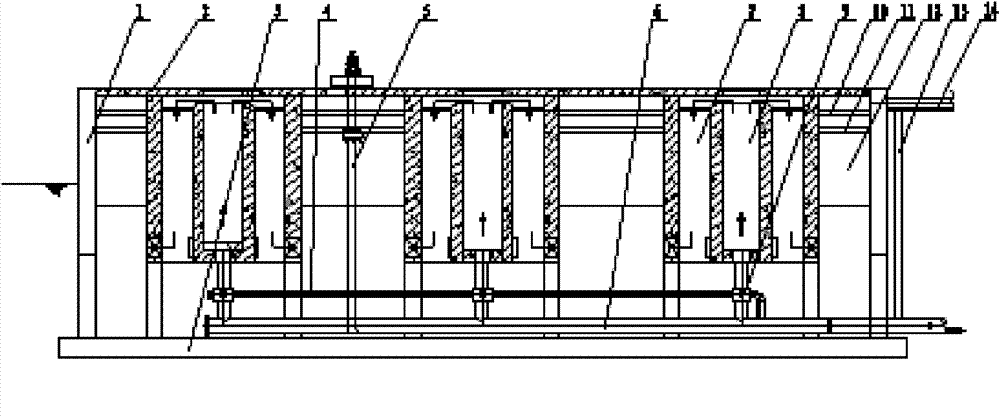

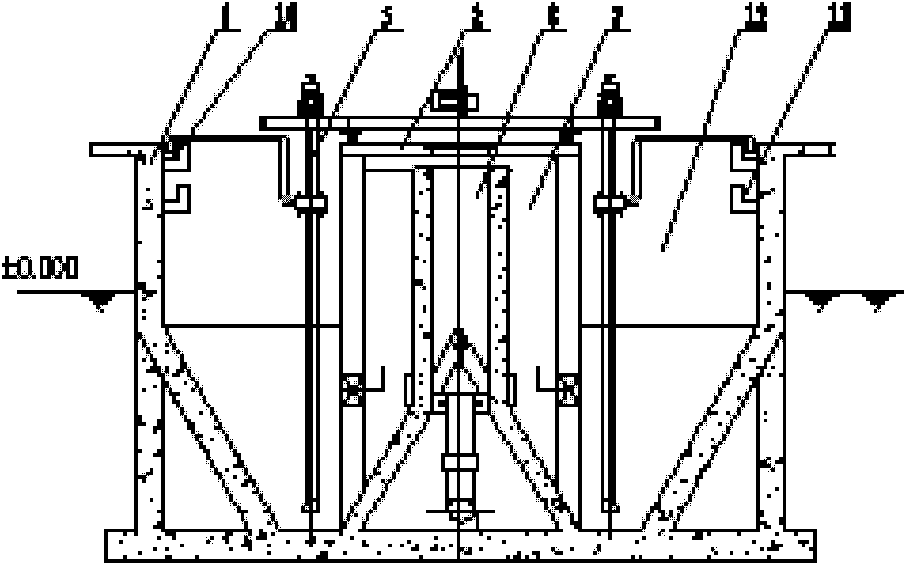

[0019] A truss-type sludge circulation clarifier, which is a cuboid or circular tank structure, including a tank wall 1, a tank bottom 3, a water inlet pipe 6, a multiphase mixer 9, a first coagulation reaction zone 8, a second Coagulation reaction zone 7, sedimentation zone 12, truss truck type sludge suction device 5, sludge return weir and channel 10, sludge return pipeline 13, outlet weir and channel 11, sludge discharge pipeline 14, etc., clarifier cover is equipped with cover plate 2 , a plurality of coagulation reaction zones are evenly distributed in the horizontal direction, and there are three coagulation reaction zones in this embodiment; Between the periphery of each coagulation reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com