System and method for constant water level sequential batch type sewage treatment system with continuous variable volume

A technology for sewage treatment and sewage treatment tanks, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of reducing structural cost, simple process structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

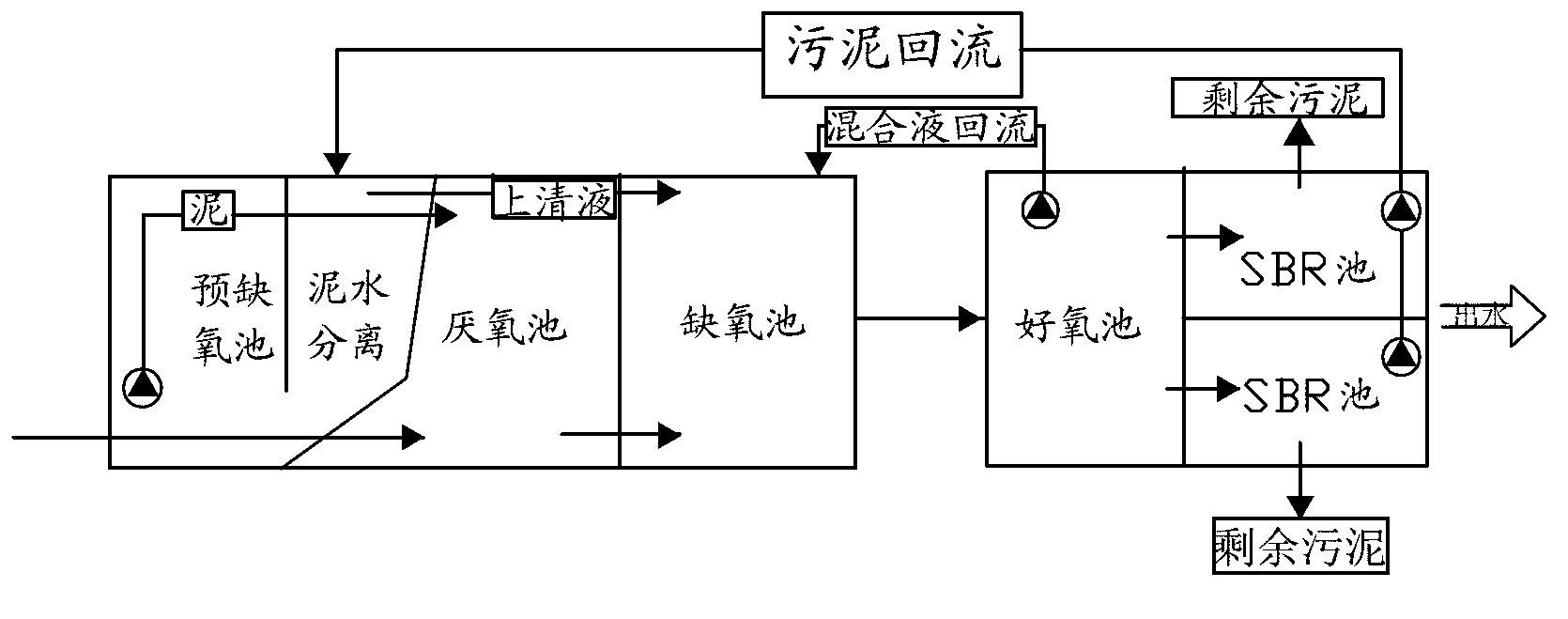

[0053] Such as Figure 4 The continuous variable volume constant water level sequence batch sewage treatment system shown includes: a sewage treatment pool 1 formed by a structural wall, the sewage treatment pool 1 is provided with an adjustable volume partition 2, and the adjustable volume The bottom and both sides of the partition are connected to the lower part and the side wall of the sewage treatment tank 1, and the upper side floats on the liquid surface, separating the sewage treatment tank into a constant water level variable volume adjustment zone A, a constant water level variable volume reaction zone B and Constant water level variable volume water quality stable area C; the constant water level variable volume adjustment area A is provided with a continuous water inlet 14 and a distribution pump 3, the water inlet of the distribution pump is set in the adjustment area, and the water outlet is set at a constant In the water level variable volume reaction zone; the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com