Phosphoric acid-sulphurous acid clarification process segmented preliming method

A technology of sulfurous acid and phosphoric acid, which is used in the purification of alkaline earth compounds, sucrose production, sugar production, etc., can solve the problems of re-decomposition and low clarification efficiency, and achieve the effect of reducing fouling, saving energy and improving clarification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

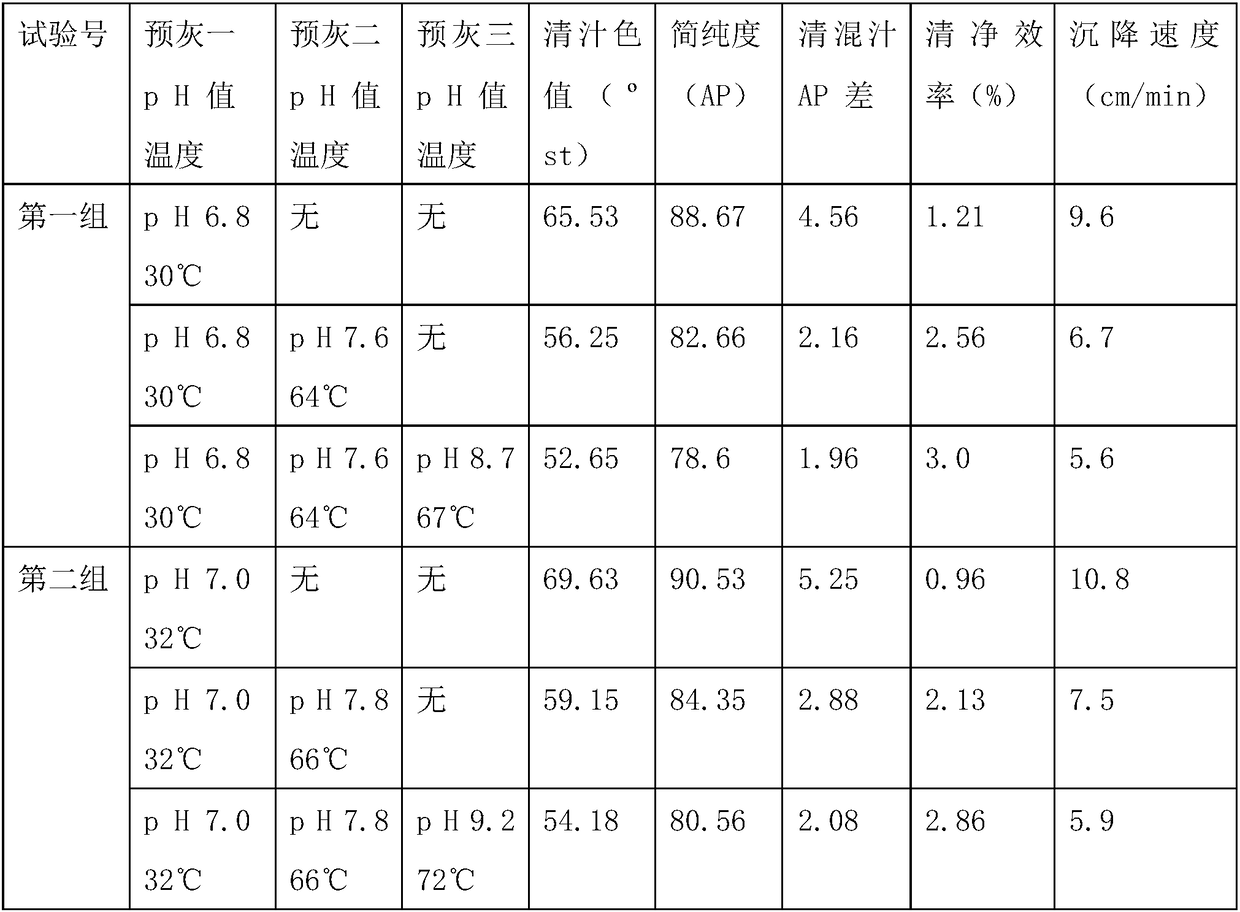

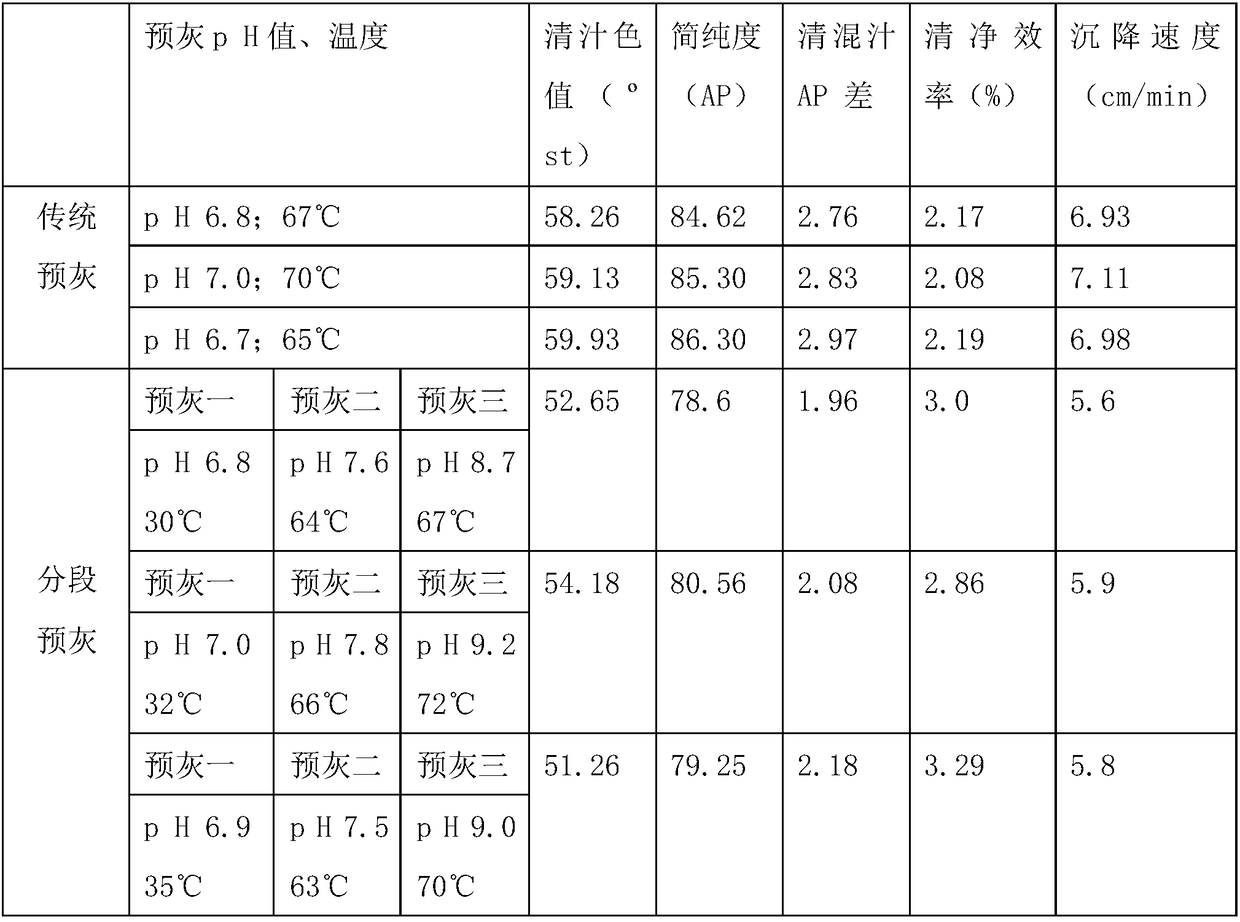

Examples

Embodiment 1

[0023] Add phosphoric acid solution to the mixed juice obtained from the pressing workshop, control the total phosphoric acid value of the mixed juice at 350mg / kg, adjust the pH value of the treated juice to 6.5 with the digested lime milk, and transfer the treated mixed juice to a constant temperature In the reaction tank, mechanically stir and react for 10 minutes at room temperature at 20°C. After the reaction, use a high-efficiency multi-stage separation sugar juice settler to separate the primary separation juice, mud juice and scum, and return the primary separation juice to the original mixed juice box; Heating to 60°C for the first time, adjusting the pH value to 7.2 with the sterilized milk of lime, reacting with mechanical stirring for 10 minutes, and part of the precipitate precipitated; heating again to 65°C for the third ash addition, using the sterilized milk of lime Add ash for the third time, adjust the pH value to 8.5, and react with mechanical stirring for 10 ...

Embodiment 2

[0025] Add phosphoric acid solution to the mixed juice obtained from the pressing workshop, control the total phosphoric acid value of the mixed juice at 450mg / kg, adjust the pH value of the treated juice to 7.2 with milk of lime, and transfer the treated mixed juice to a constant temperature In the reaction tank, mechanically stir and react for 15 minutes at room temperature at 35°C. After the reaction, use a high-efficiency multi-stage separation sugar juice settler to separate the primary separation juice, mud juice and scum, and return the primary separation juice to the original mixed juice tank; Heating to 68°C for the first time to add ash for the second time, adjust the pH value to 8.0 with the sterilized milk of lime, and react with mechanical stirring for 15 minutes, and part of the precipitate precipitates; heat again to 75°C, use the sterilized milk of lime Carry out the third ash addition, adjust the pH value to 9.5, and react with mechanical stirring for 15 minute...

Embodiment 3

[0027] Add phosphoric acid solution to the mixed juice obtained from the pressing workshop, control the total phosphoric acid value of the mixed juice at 400mg / kg, adjust the pH value of the treated juice to 6.7 with milk of lime, and transfer the treated mixed juice to a constant temperature In the reaction tank, mechanically stir and react for 15 minutes at room temperature at 25°C. After the reaction, use a high-efficiency multi-stage separation sugar juice settler to separate the primary separation juice, mud juice and scum, and return the primary separation juice to the original mixed juice tank; Heating to 62°C for the first time to add ash for the second time, adjust the pH value to 7.4 with the sterilized milk of lime, react with mechanical stirring for 15 minutes, and part of the precipitate precipitates; heat again to 67°C, use the sterilized milk of lime Add ash for the third time, adjust the pH value to 8.7, and react with mechanical stirring for 15 minutes. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com