Exhaust gas aftertreatment device

A technology of exhaust gas post-treatment and heating device, which is applied in the direction of electronic control of exhaust gas treatment device, diagnosis device of exhaust gas treatment device, exhaust gas treatment, etc., and can solve problems such as power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

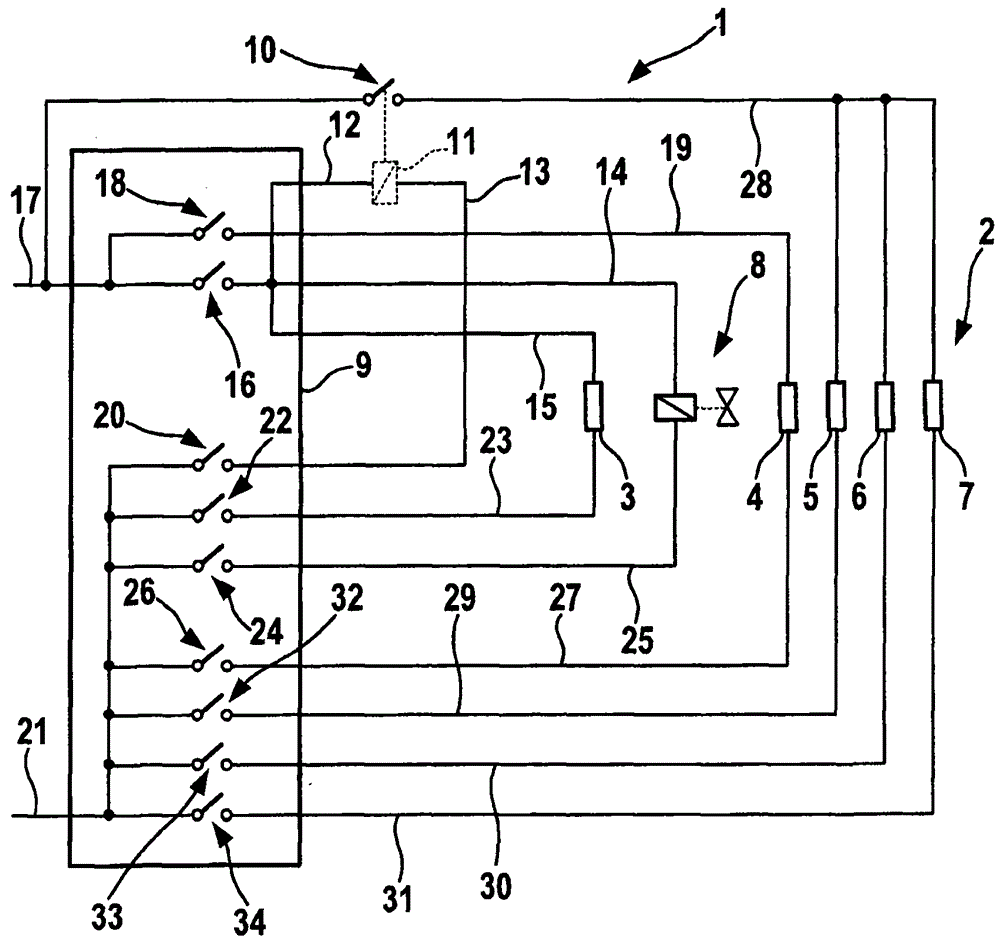

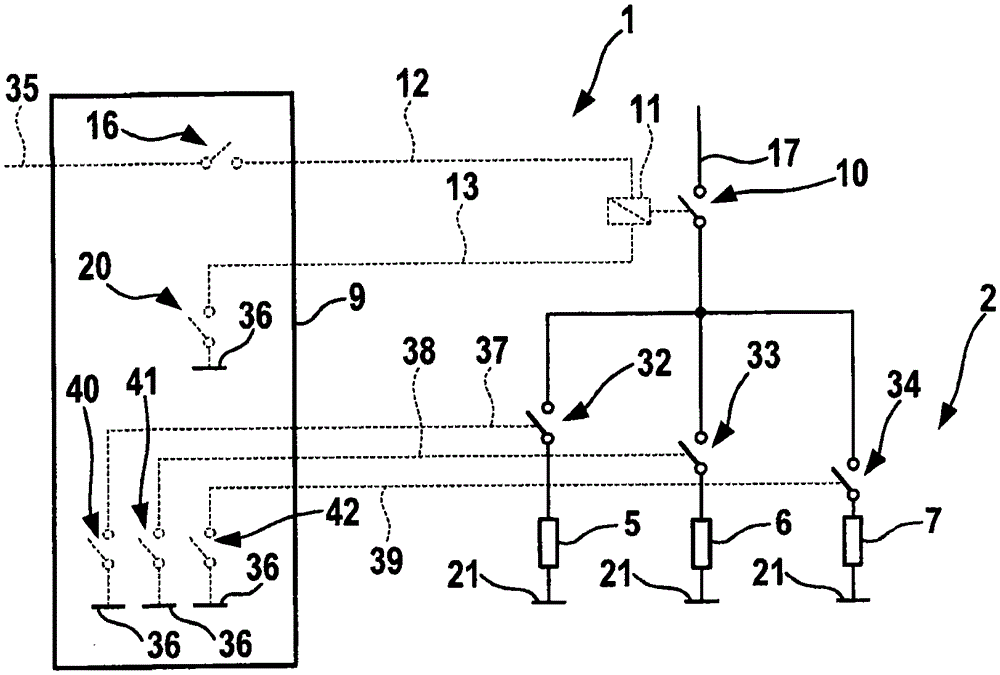

[0016] figure 1 A part of an exhaust gas aftertreatment system 1 of a motor vehicle is shown. The exhaust gas aftertreatment device 1 includes, for example, a heating device 2 with five heating elements 3 , 4 , 5 , 6 , 7 and a switching valve 8 . The heating elements 3 , 4 , 5 , 6 and 7 are designed, for example, as heating wires, heating wires or the like, and a switch valve 8 can be used to release or disconnect a not shown for discharging the heating elements 3 to 7 . Coolant circuit for heat. The heating device 2 is associated with an SCR system, wherein it serves to heat at least one line via which a working medium (for example water-urea solution) is fed to a catalytic converter (not shown). The commonly used water-urea solution freezes at approximately −10° C., so at low ambient temperatures the lines must be heated by means of the heating device 2 in order to melt or maintain the fluid state of the water-urea solution. The heat of at least one of the heating element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com