Liquid chromatography high-pressure parallel cam pump

A liquid chromatography, cam pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve problems such as large pressure fluctuations, reducing the normal service life of the sealing ring, and the detection system brings stable flow and high detection accuracy. The effect of reducing pressure pulsation and protecting service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

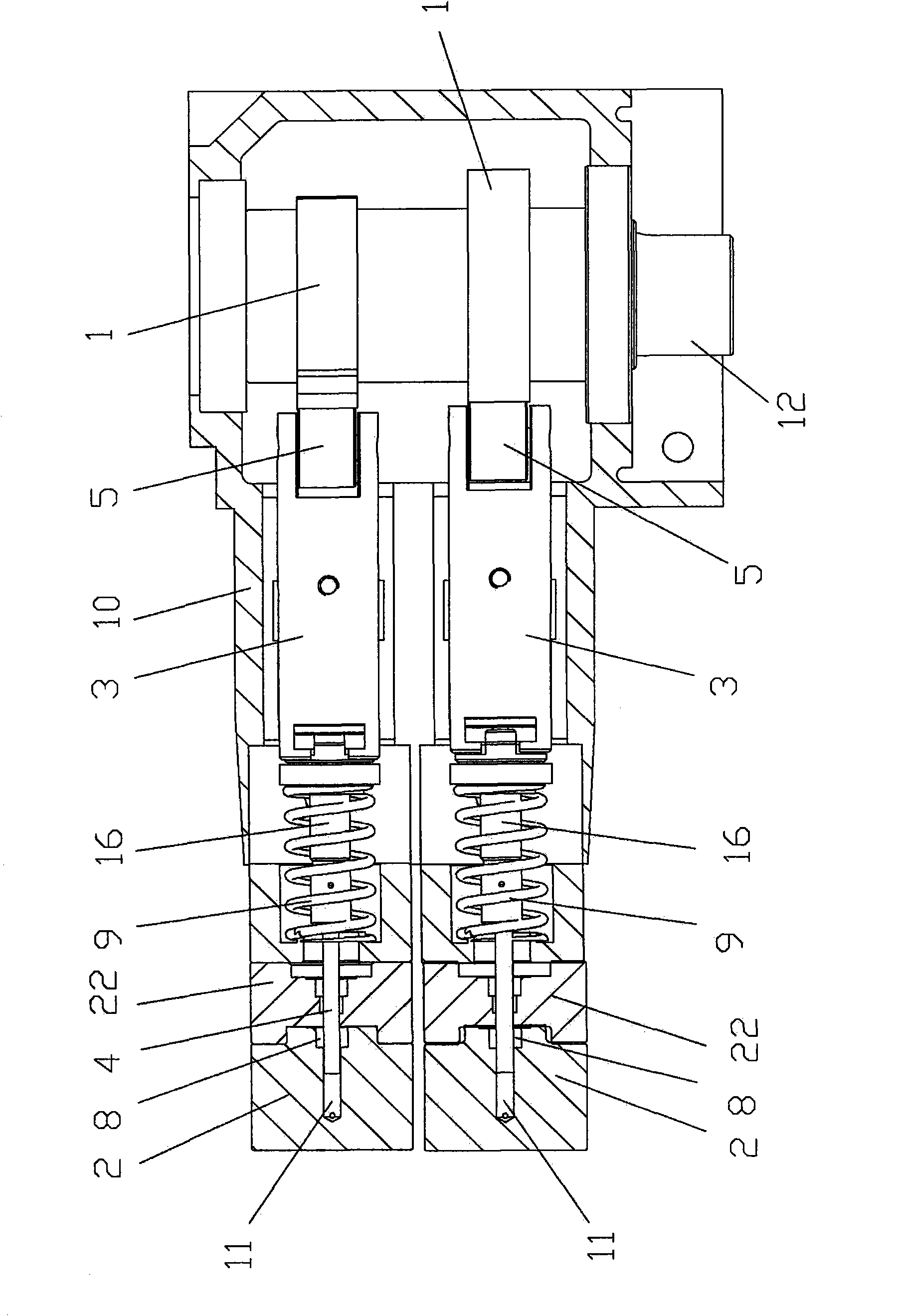

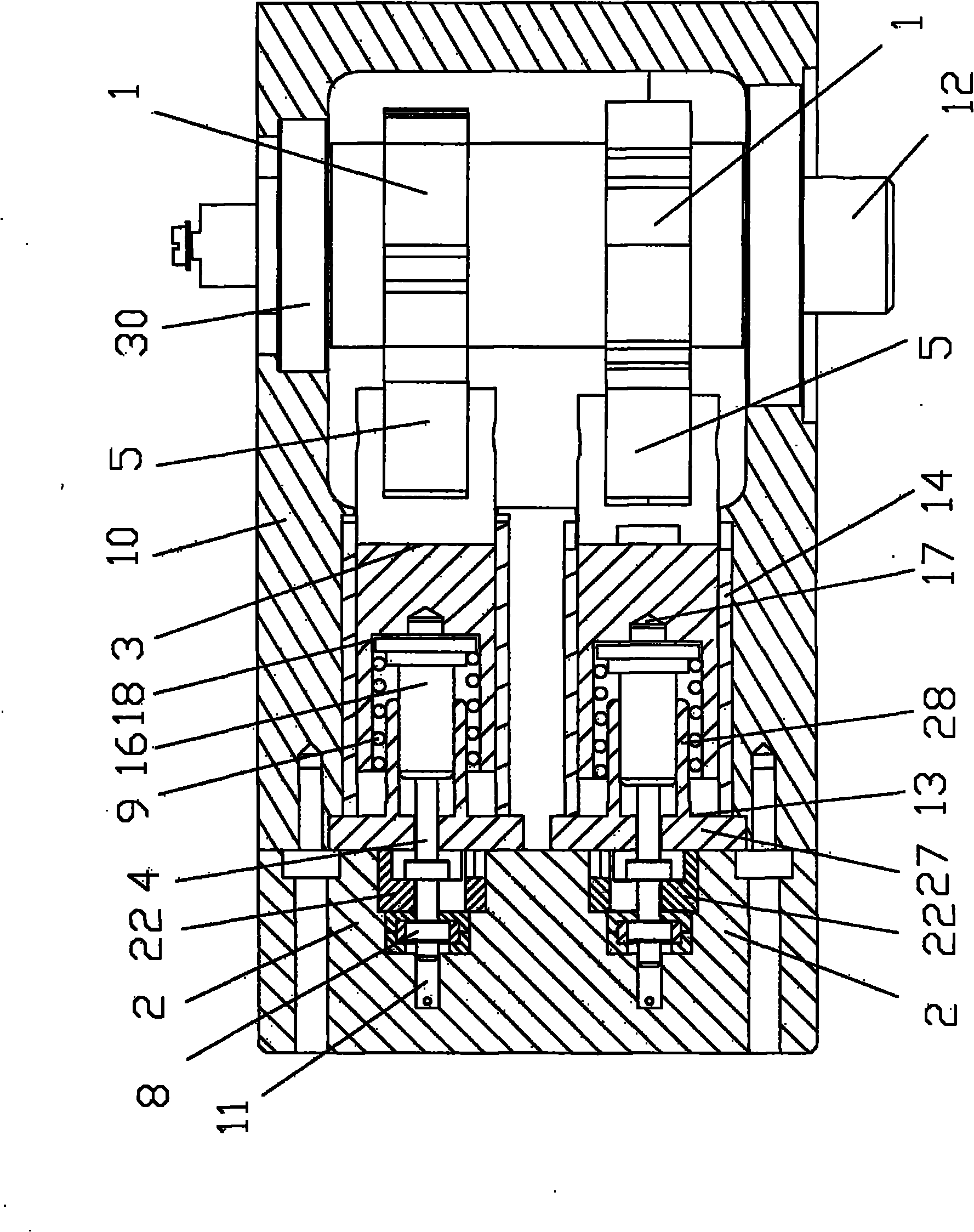

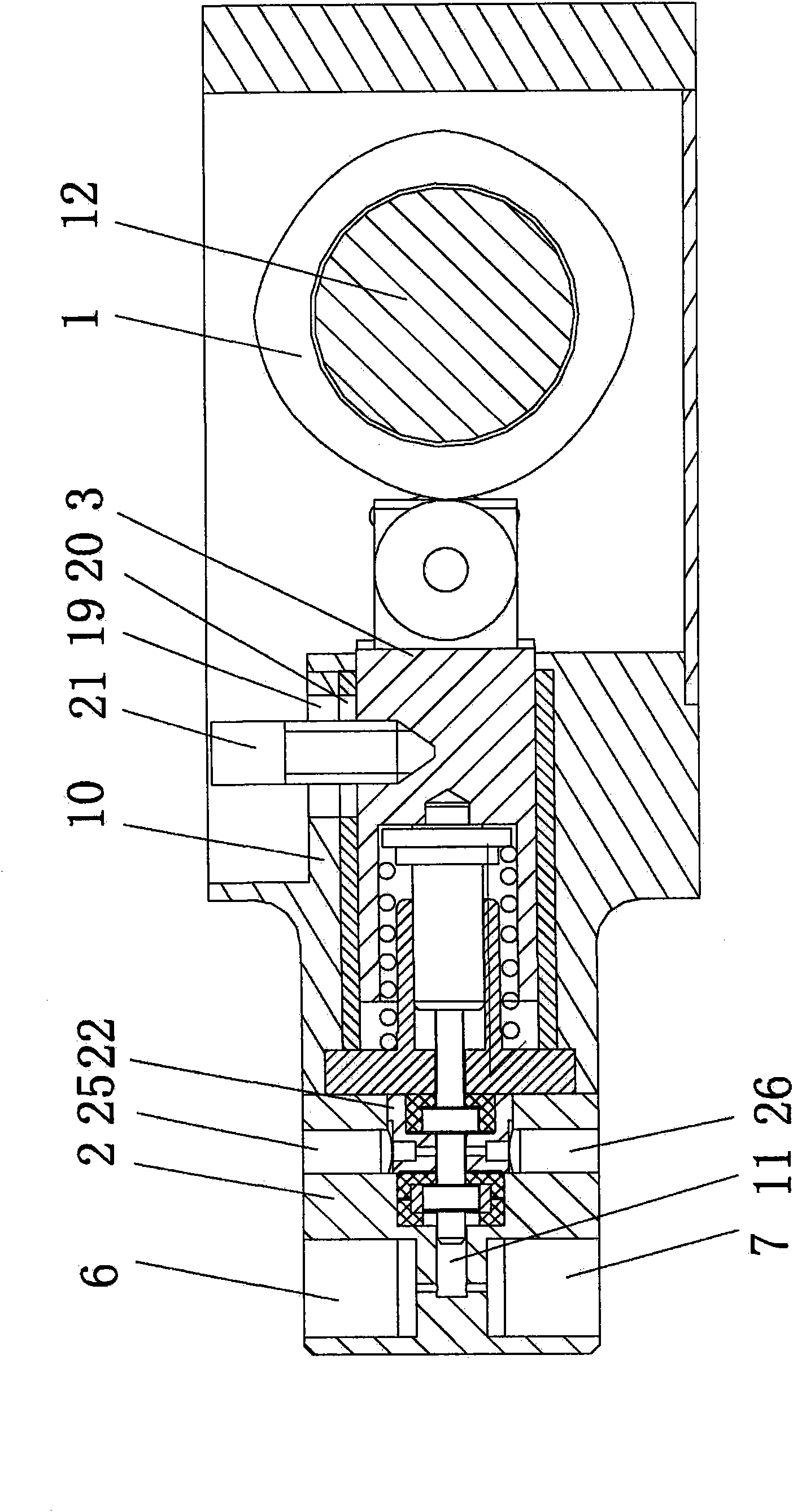

[0031] Such as figure 2 , image 3 , Figure 4 As shown, the liquid chromatography high-pressure parallel cam pump of the present invention includes: a motor, a pump main body 10, two cleaning blocks 22 with a liquid inlet and a liquid outlet, a camshaft 9 connected to the motor, and a camshaft 9 fixedly connected to the camshaft 9 Two cylindrical cams 1 with the same shape, two pump heads 2 fixedly connected with the pump main body 10, the camshaft 9 is connected with the pump main body 10 through a bearing 30, and each cylindrical cam 1 is connected to the pump body through a set of reciprocating liquid delivery mechanism. A pump head 2 is connected; each set of reciprocating liquid delivery mechanism includes a roller 5, a plunge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com