Mechanical sealing ring of biomimetic fish scale groove

A mechanical seal and sealing ring technology, applied in the field of bionic fish scale groove sealing ring, can solve the problems of large opening force, friction and wear of the sealing ring, and short service life of the sealing device, so as to reduce abrasive wear, reduce the degree of friction and wear, prolong the The effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

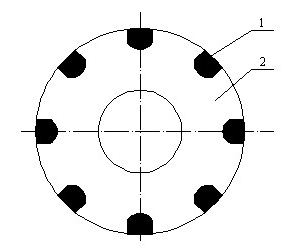

[0012] Embodiment 1: As shown in the figure, the high pressure side of the bionic fish scale groove mechanical seal ring is on the outer diameter side of the seal ring, and there are 8 fish scale grooves evenly distributed in the circumferential direction on the high pressure side, and the fish scale grooves are radial linear grooves and circumferential arc grooves The combination of the radial linear groove extends to the edge of the outer diameter of the ring, and the circumferential arc groove part is away from the outer diameter of the ring. The length of the groove is 0.5 times the width of the sealing ring, and the width It is 0.15 times the ratio of the outer diameter of the sealing ring to the number of grooves; each groove is an arc-shaped bottom groove with a shallow radial depth, and the outer diameter edge of the high-pressure side is the shallowest point of 0.001mm, and the groove length is 1 / 3 ( The deepest part is 0.5 mm from the edge of the outer diameter of th...

Embodiment 2

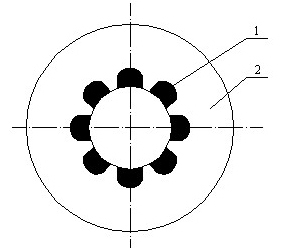

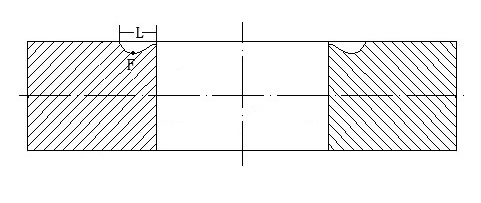

[0013] Embodiment two: if figure 2 , 3 As shown, the high pressure side of the bionic fish scale groove mechanical seal ring is on the inner diameter side of the seal ring, and a fish scale groove is evenly distributed in the circumferential direction on the high pressure side, and the fish scale groove is a combination of radial linear grooves and circumferential arc grooves. The part of the linear groove extends to the edge of the inner diameter of the ring, and the part of the circumferential arc groove is away from the inner diameter of the ring. The length of the groove is 0.75 times the width of the sealing ring, and the width It is 0.3 times the ratio of the outer diameter of the seal ring to the number of grooves; each groove is an arc-shaped bottom groove with a shallow radial depth, and the outer diameter edge of the high-pressure side is the shallowest part of 4 mm, and the groove length is 2 / 3 ( The deepest point (point F) at a distance of 5 mm from the edge of ...

Embodiment 3

[0014] Embodiment 3: As shown in the figure, the high pressure side of the bionic fish scale groove mechanical seal ring is on the outer diameter side of the seal ring, and there are 6 fish scale grooves evenly distributed in the circumferential direction on the high pressure side, and the fish scale grooves are radial linear grooves and circumferential Combination of arc-shaped grooves, the radial linear groove part extends to the edge of the outer diameter of the ring, and the circumferential arc-shaped groove part is away from the outer diameter of the ring. The length of the groove is 0.65 times the width of the sealing ring It is 0.25 times the ratio of the outer diameter of the seal ring to the number of grooves; each groove is an arc-shaped bottom groove with a shallow radial depth, and the outer diameter edge of the high-pressure side is the shallowest part of 0.01mm, and the groove length is 1 / 2 ( The deepest part is 3 mm from the edge of the outer diameter of the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com