Circular tube connector

A technology of connectors and round pipes, which is applied in the direction of sleeve/socket connections, pipes/pipe joints/fittings, couplings, etc., which can solve the problem of increasing the outer diameter of pipe joints, increasing the expansion process of pipe joints, and inappropriate structures and other problems, to achieve the effect of doubling the degree of sealing, reducing processing costs and improving appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

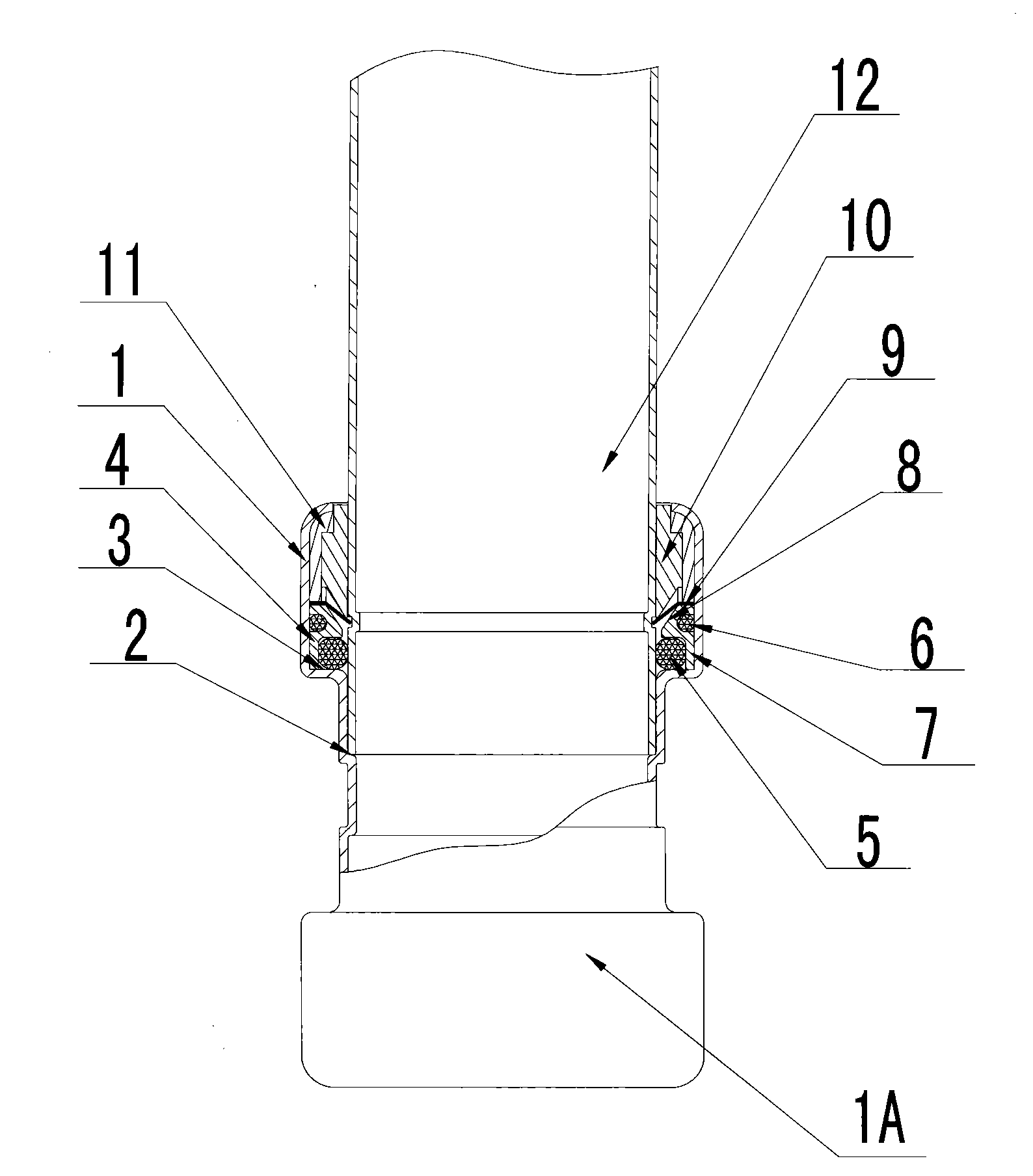

[0031] Embodiment 1 is the embodiment in which an inner sealing ring and an outer sealing ring are arranged on the inner wall and the outer wall of the circlip supporting body respectively: please refer to figure 1 , Figure 10 , including straight-through round pipe connector body 1A, interface 1, first step 2, second step 3, circlip support body 4, inner sealing ring 5, outer sealing ring 6, round tube pin 7, inner cone 8, and circlip 9, snap spring supports 10, pressure sleeve 11, round pipe 12.

[0032] Such as figure 1 As shown: a straight-through round pipe connector body 1A is placed vertically, and the interface 1 for the insertion of the round pipe 12 is provided upwards, and the first step that limits the insertion depth of the round pipe 12 is provided in the interface 1 from bottom to top in the axial direction 2. Place the circlip supporting body 4, the inner seal ring 5, the outer sealing ring 6, the circlip 9, the circlip support 10, the second step 3 of the p...

Embodiment 2

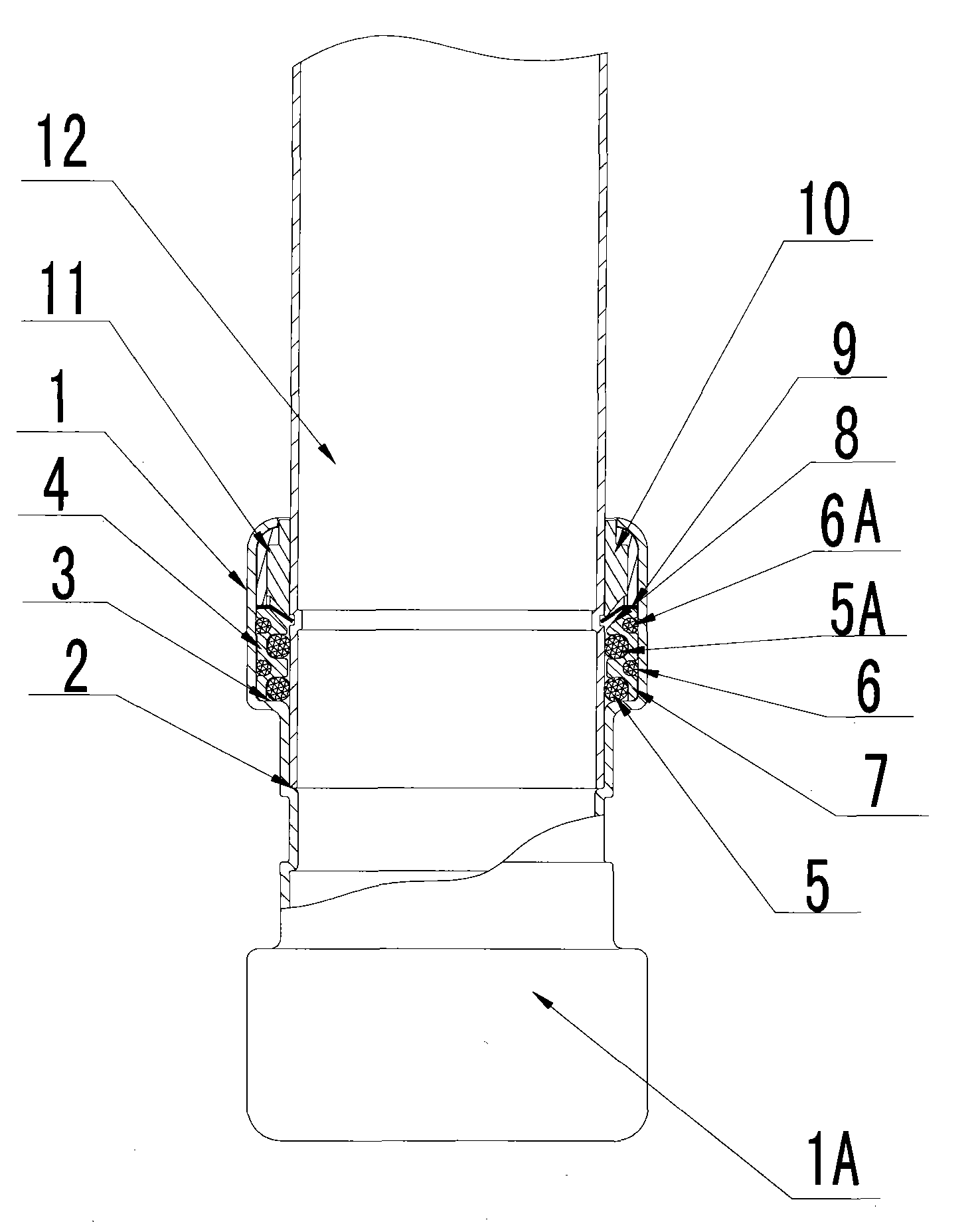

[0033] Embodiment 2 is an implementation mode in which more than one inner sealing ring and outer sealing ring are arranged on the inner wall and outer wall of the circlip supporting body: please refer to figure 2 , Figure 10 , including interface 1, first step 2, second step 3, circlip support body 4, inner sealing ring 5, inner sealing ring 5A, outer sealing ring 6, outer sealing ring 6A, round pin 7, inner cone 8, Circlip 9, circlip support 10, pressure sleeve 11, round pipe 12.

[0034] Such as figure 2 As shown, the second embodiment is similar to the first embodiment, except that the axial dimension of the circlip supporting body 4 is appropriately increased, and at the same time, a groove is respectively added on the inner wall and the outer wall, and the corresponding inner sealing ring 5A and outer sealing ring 6A are arranged respectively. , the rest of the structures and functions are the same as those in Embodiment 1.

Embodiment 3

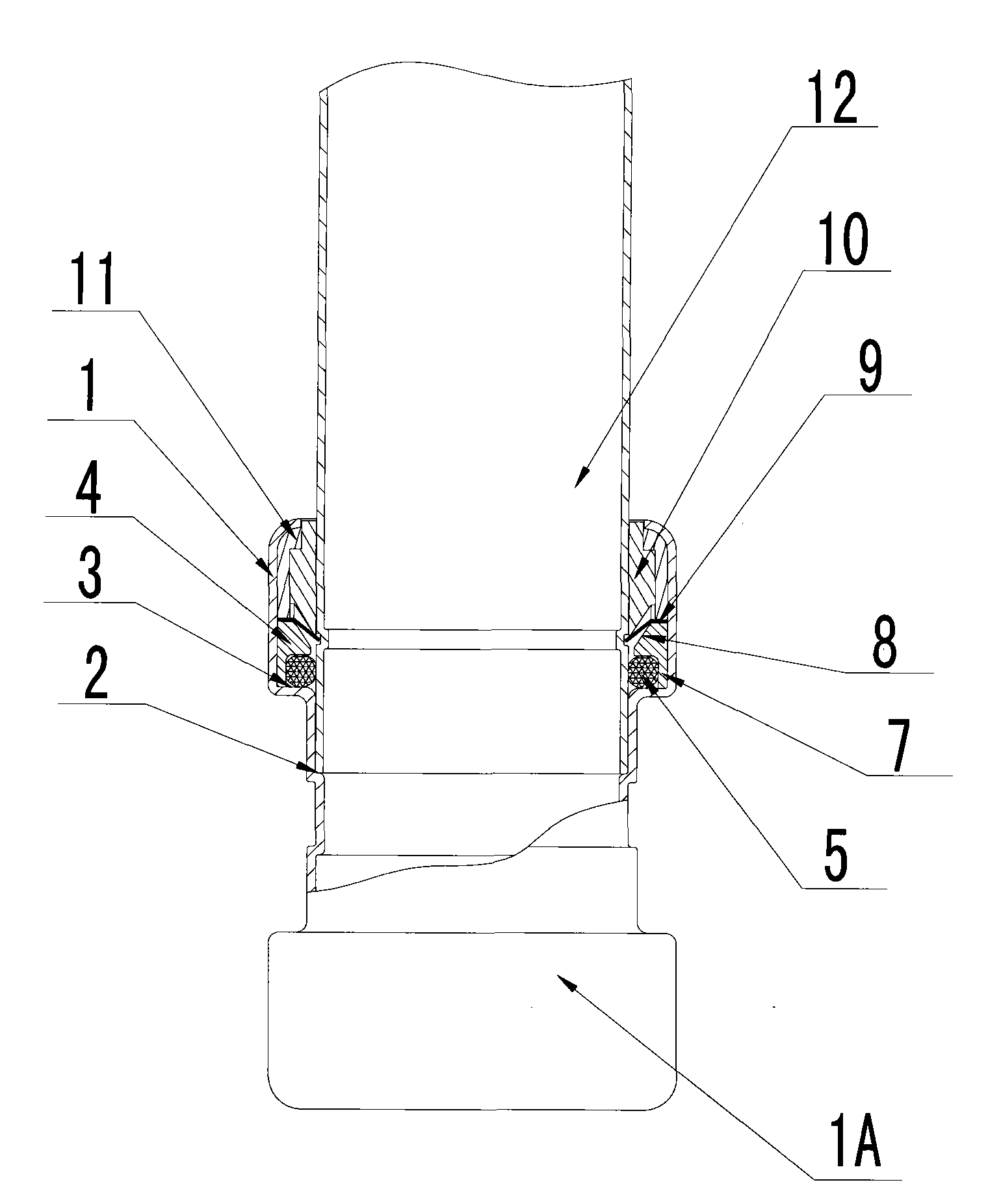

[0035] Embodiment 3 is the embodiment in which the inner sealing ring is only placed on the inner wall of the circlip supporting body: please refer to image 3 , Figure 10 , including interface 1, first step 2, second step 3, circlip support body 4, inner sealing ring 5, round tube pin 7, inner cone 8, circlip 9, circlip support 10, pressure sleeve 11, round tube 12.

[0036] Such as image 3 As shown, the difference between the third embodiment and the first embodiment is that the outer wall of the circlip supporting body 4 is not provided with a groove and no outer sealing ring is installed, and the outer wall of the circlip supporting body 4 and the interface 1 are sealed in a tight fit. , the rest of the structures and functions are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com