Fuel system diagnostics by analyzing cylinder pressure signal

A cylinder pressure and pressure technology, which is applied in the field of compression ignition engines, can solve problems such as variability affecting cylinder heat release and work output, and engine non-optimal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

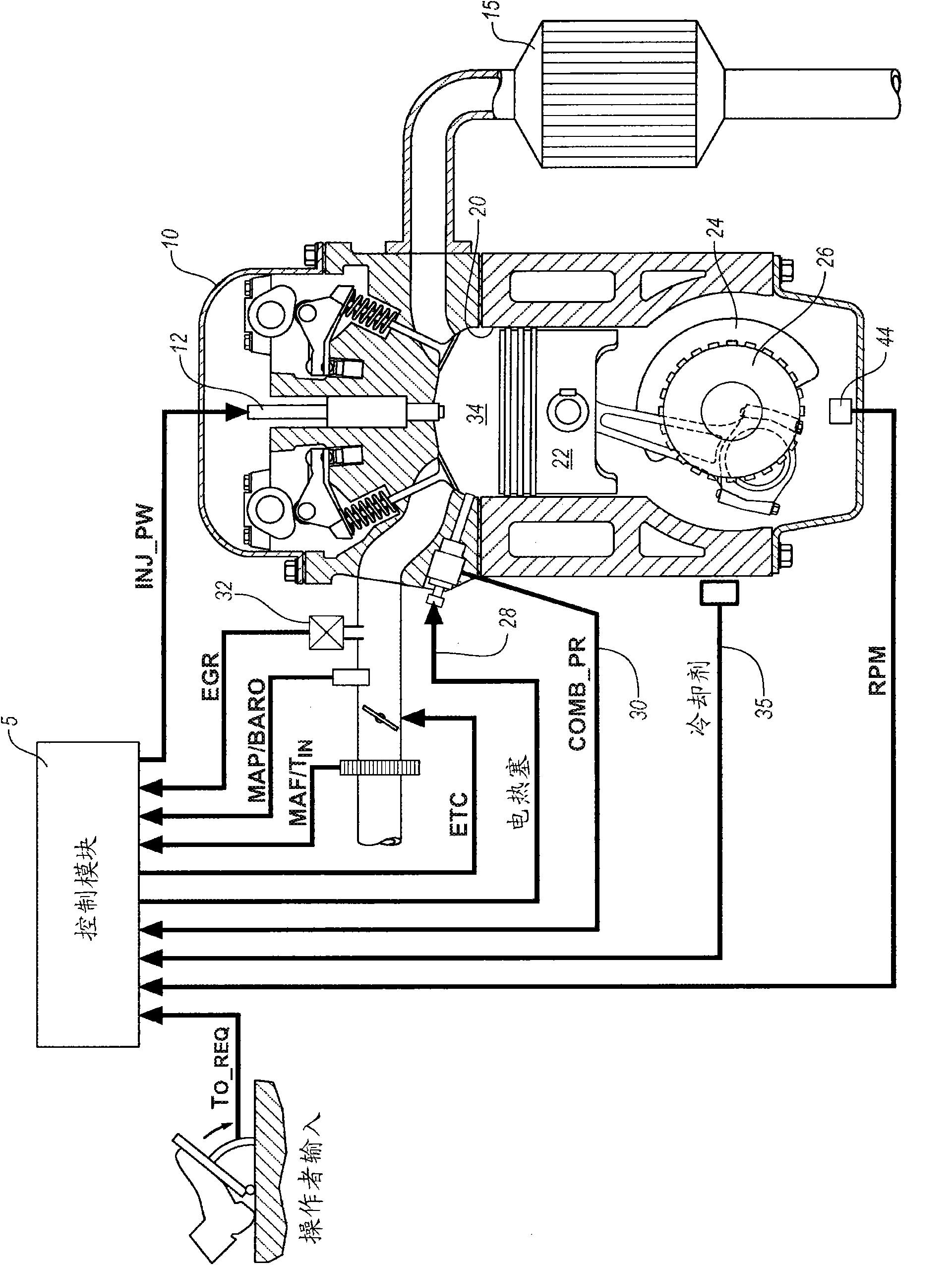

[0016] With reference to the accompanying drawings, wherein the drawings are for the purpose of illustrating specific embodiments only, and are not intended to be limiting to specific embodiments, figure 1 For schematic purposes, an internal combustion engine 10 , a control module 5 and an exhaust aftertreatment system 15 constructed in accordance with an embodiment of the present disclosure are shown. An exemplary engine includes a multi-cylinder direct injection compression ignition internal combustion engine having a reciprocating piston 22 connected to a crankshaft 24 and movable within cylinders 20 defining a variable volume combustion chamber 34 . Crankshaft 24 is operatively connected to the vehicle transmission and driveline to deliver tractive torque to the transmission and driveline in response to an operator torque request (TO_REQ), the engine preferably using a four-stroke operation wherein each engine combustion cycle includes 720 degrees As the crankshaft 24 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com