Light guide plate, and method for producing the same

A manufacturing method and technology of light guide plate, applied in the direction of light guide, optics, light source, etc., can solve the problems of inflexible elastic film forming pattern, ink or resin damage or peeling, etc., and achieve the effect of high reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

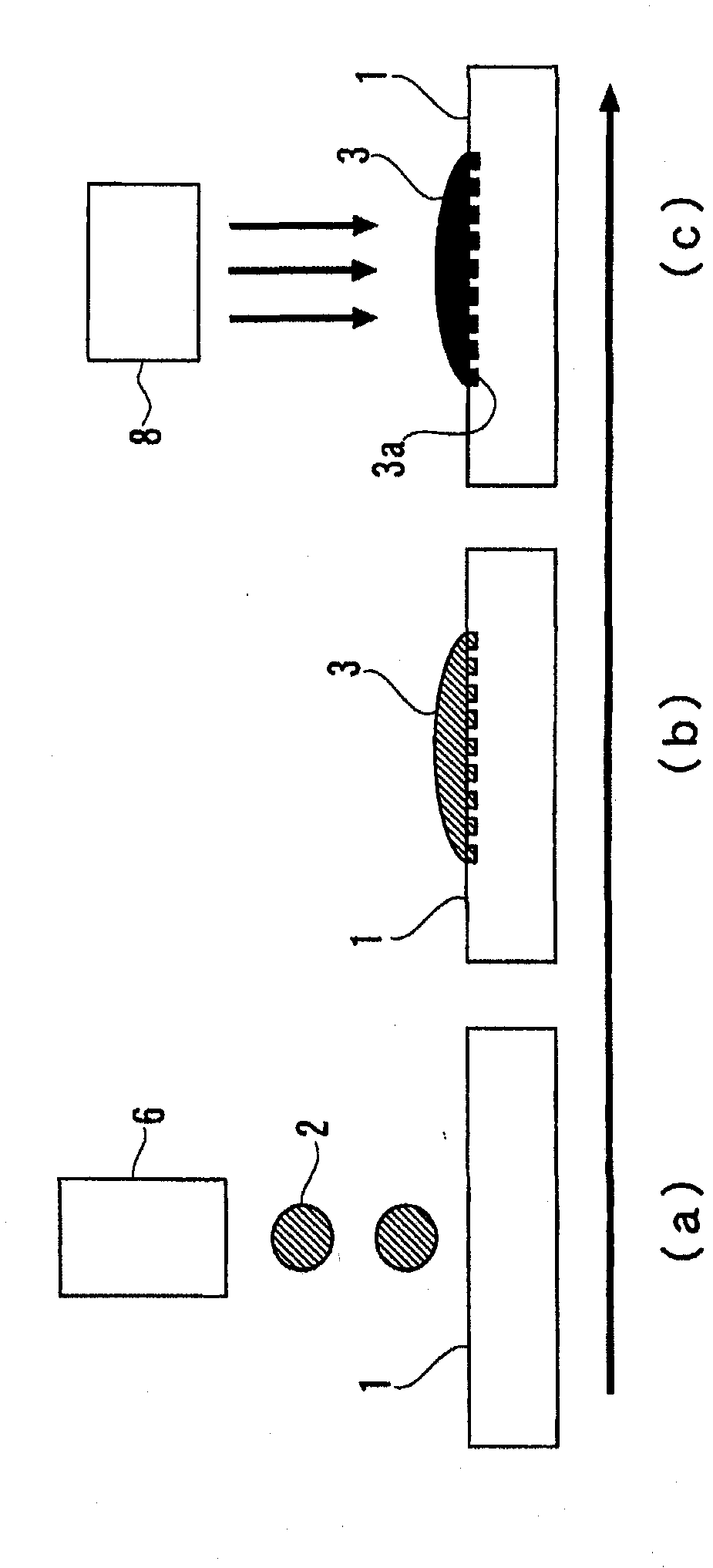

[0061] Next, a first example according to the present invention will be described. In this example, a thermosetting polyurethane film having a thickness of 200 μm was used as the base material 1 . For the printing ink, UV curable white ink A (main component: 70 to 90% by weight of the photopolymerizable composition; pigment: 10 to 20% by weight of titanium dioxide; and the remainder: 5% by weight or more less polymerization initiator). As the inkjet head 6, a piezoelectric type inkjet head was used under the conditions of 360 dpi and a small droplet volume of 14 pl. As a UV curing device, Subzero (manufactured by Integration Inc.) was used.

[0062]

[0063] In order to compare the bonding strength of UV-curable white ink A to base material 1 according to this example and the combination of each of the other base materials, the combination of base material and UV-curable white ink A was swollen degree test. The swelling degree test was performed by soaking a sample piece...

no. 2 example

[0075] In this example, a white ink different from that used in the first example was selected and tested in the same manner as in the first example. In this example as well, it was found that a combination of the white ink and a thermosetting polyurethane film serving as a base material could obtain sufficient bonding strength.

[0076] In this example, printing was performed using white ink under the following conditions. A thermosetting polyurethane film having a thickness of 200 μm was used as the base material 1 . As the white ink, UV-curable white ink B (main component: 65 to 75% by weight of acrylate; and pigment: 15 to 25% by weight of titanium dioxide) was used. The same inkjet head 6 and UV curing device 8 as in the first example were used.

[0077] For this base material and ink combination, the swelling degree test and the keystroke test were performed in the same manner as in the first example. The same results as in the first example were obtained.

[0078] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com