Aluminum profile hot-extrusion shunt combined die structure

A combined mold and hot extrusion technology, which is applied in the direction of metal extrusion molds, etc., can solve the problems of increasing cost and affecting the strength of the mold, and achieve the effects of reducing openings, increasing strength, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

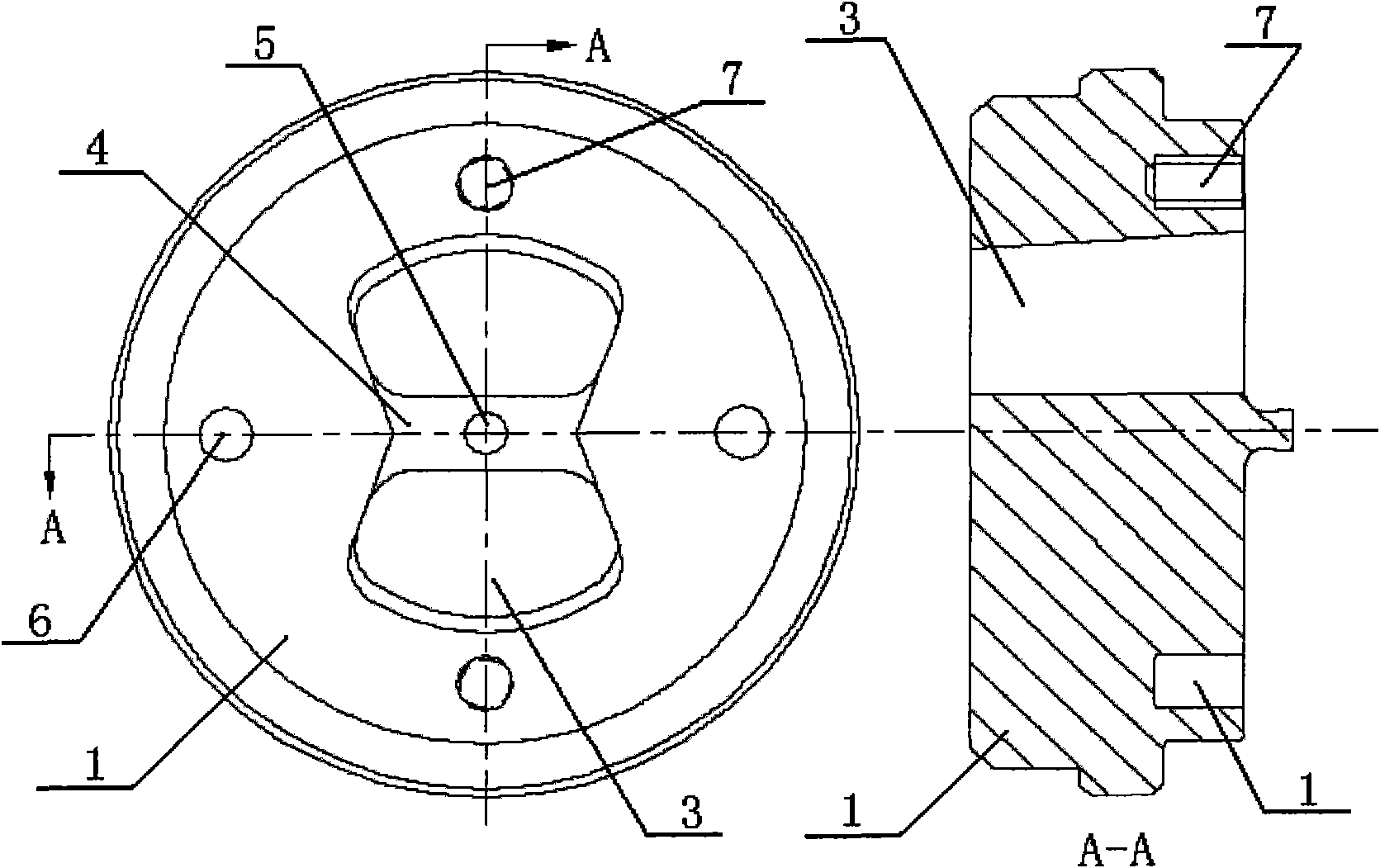

[0016] Such as figure 1 As shown, the upper mold 1 is provided with a shunt hole 3, a shunt bridge 4, and a mold core 5; the shunt hole 3 is a channel for the metal to lead to the lower mold hole, and the shunt bridge 4 is a bracket supporting the mold core 5, and the mold core 5 is used to Form the shape and size of the cavity of the profile.

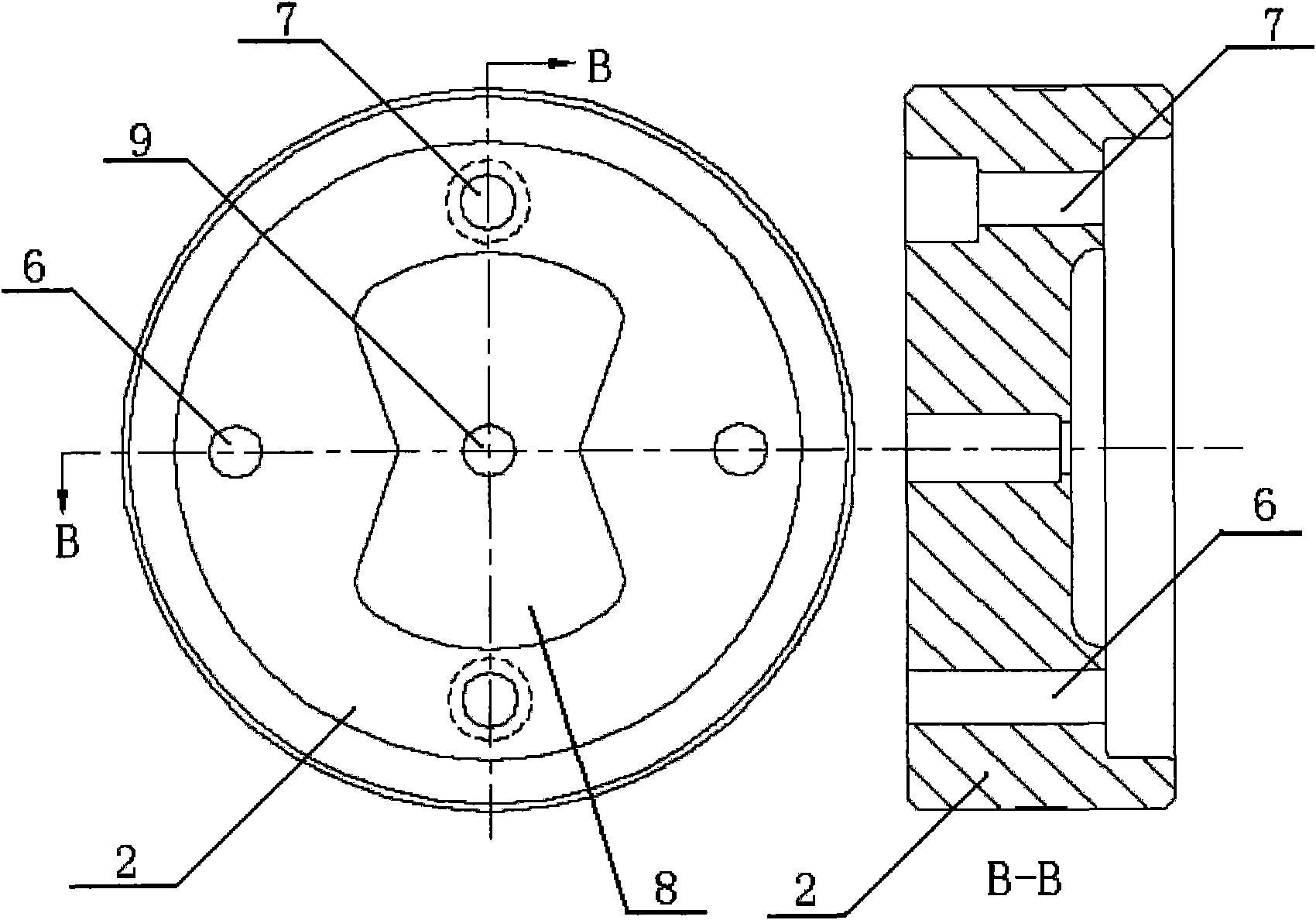

[0017] Such as figure 2 As shown, there is a welding chamber 8 and a mold cavity 9 on the lower mold 2; the welding chamber 8 gathers the metal flowing out of the shunt hole and welds them together again to form an integral material centered on the mold core 5. Continuous accumulation, static pressure constantly increases, until the metal is extruded out of the mold cavity 9.

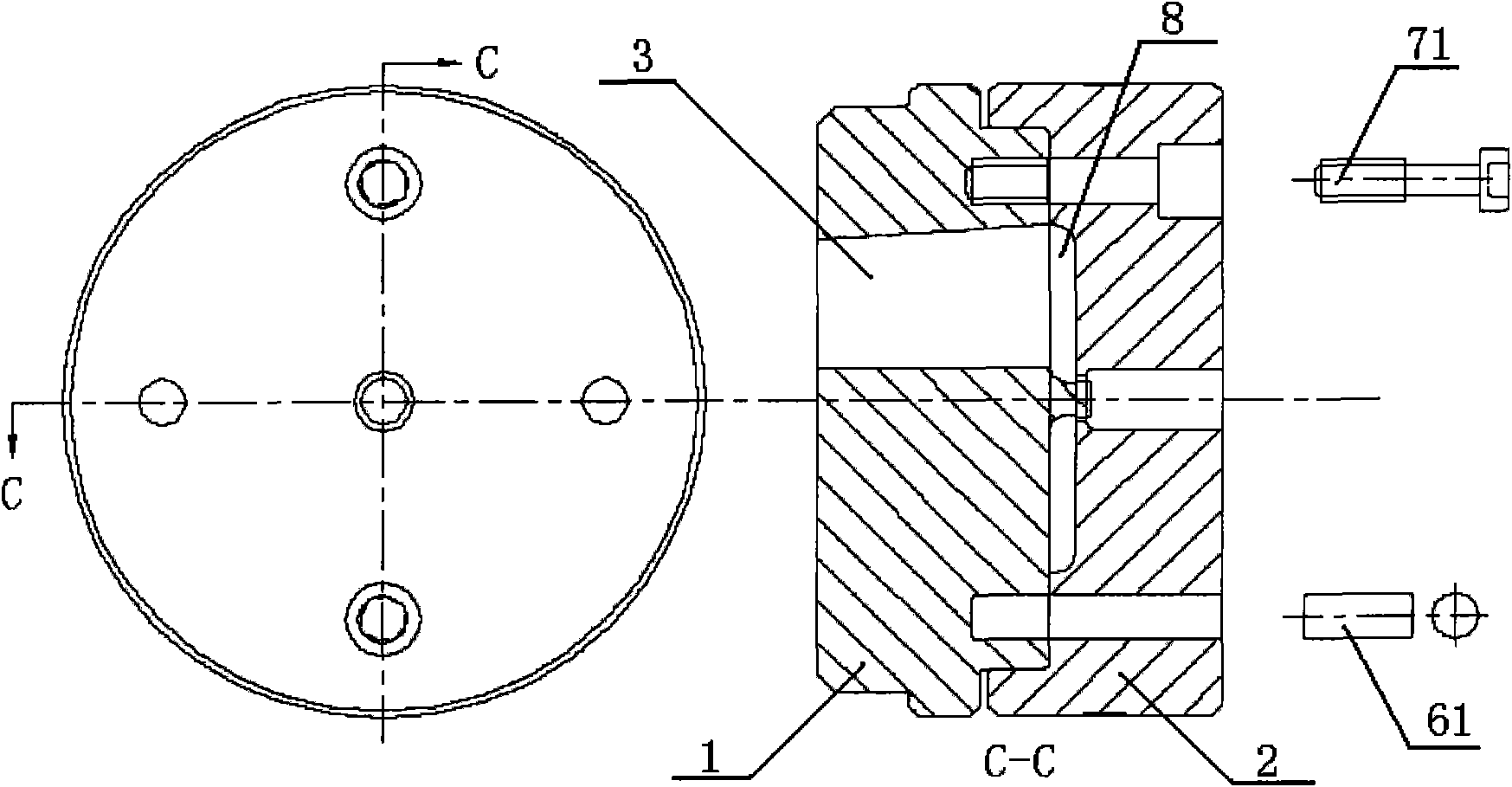

[0018] Such as figure 1 , figure 2 As shown, both the upper die 1 and the lower die 2 are provided with a set of screw holes 7 and a set of posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com