Molding die for telescoping pipe composite structure

A technology of combined structure and forming mold, applied in the field of die-casting mold and plastic forming mold, can solve the problems of difficult processing, installation, debugging and maintenance, increase mold cost, waste mold steel and other problems, achieve beautiful product quality and save mold steel. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

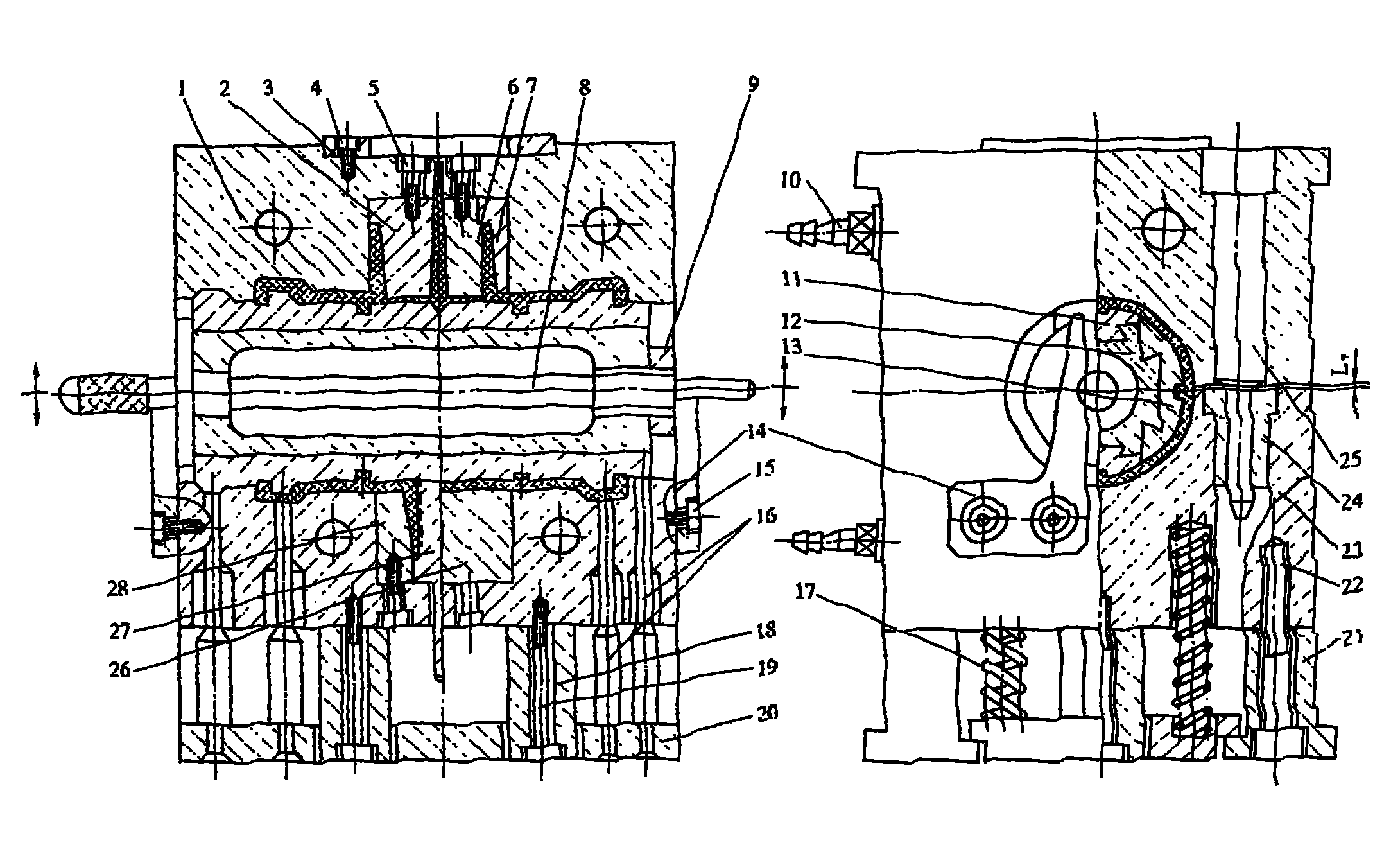

[0015] Shown in the figure is a forming die for the combination structure of a pair of reducing pipe fittings. When the mold was clamped to the die-casting machine, since the core 2, the core 6, the insert ring 7, the silk core 27, the insert ring 28 and the plug 26 were all movable. If the plug is installed, the straight expansion joint can be produced. Replace a core 2 to produce a variable diameter tee. Change two pieces of insert ring 7 and mold core 6, can produce variable diameter four-way pipe etc. In order to form the grooves on both ends of the inner wall, its forming main core adopts the structural form of an assembled assembly, consisting of mandrel 8, tightening nut 9, main block 12, small block 11 and large block 13. When the product is ejected together with the main core, the mandrel 8 and the main block will be pulled out together by the worker or machine at the back, and then the two small blocks 11 will be clamped inward, and the two small blocks 11 will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com