Underground drilling and fracturing-integrated staged fracturing device and gas drainage process

A technology of staged fracturing and weight-on-bit, which is applied in gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of affecting the permeability coefficient of coal seams, increasing the cost of single-hole fracturing, and reducing the efficiency of single-hole fracturing. Achieve the effect of improving single-hole drainage capacity, enhancing coal seam permeability, and eliminating gas disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

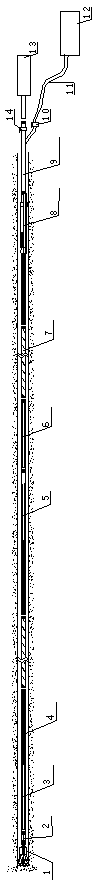

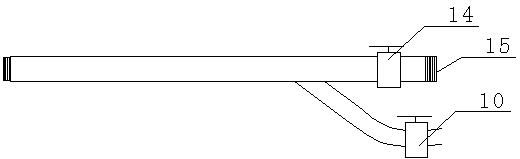

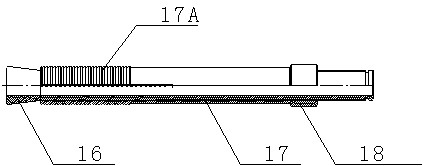

[0032] Depend on Figure 1-Figure 7 Shown is an integrated staged fracturing device for downhole drilling and pressure drilling, which includes a drill bit 1, a first packer 3, a first segmented drill pipe 4, an interception and water diversion rod 5, The second packer 6, the second segmented drill pipe 7, and the function conversion rod 9 are connected with an orifice anchor 8 between the second segmented drill rod 7 and the function conversion rod 9, and the function conversion rod 9 is Hollow tubular, the function conversion rod 9 is connected to the high-pressure water pump 12 through the pipeline 11, the high-pressure water pump 12 is connected to the water tank for water injection (not shown in the water tank figure), and the pipeline 11 connected to the high-pressure water pump 12 is connected to one side of the outer wall of the function conversion rod 9 A second ball valve 10 is provided on the pipeline 11 at the rear side of the connection between the pipeline 11 and...

Embodiment 2

[0034] Depend on Figure 8-Figure 10 The downhole drilling and pressure-drilling integrated staged fracturing gas drainage process shown is implemented on the basis of Example 1, and the steps are as follows: first select the fracturing site; then determine the drilling parameters to construct the drilling, drilling Parameters include hole length, hole height, hole diameter, inclination angle, and azimuth angle; then design hydraulic fracturing, including the number of fracturing stages, the length of each fracturing stage, fracturing time, the amount of water injected into each stage of fracturing, and the injection pressure; After the downhole drilling pressure integrated staged fracturing device described in Example 1 is assembled, the drilling rig 13 is opened to drill into the coal seam drilling, and then the drilling is stopped, and a ball 24 is put into the second ball valve 10 to close the second ball valve 13. A ball valve 14, open the second ball valve 10, open the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com