Door type composite pipe roof umbrella arch structure for tunnel opening and construction method thereof

A technology of composite pipe and arch structure, which is applied in the direction of basic structure engineering, tunnel, tunnel lining, etc., can solve the problems of displacement and cracking of pipe shed arches, large subsidence in the cave, cracking, slipping, etc., and achieves improved economic efficiency. Sex and construction efficiency, reducing the height of construction excavation, and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

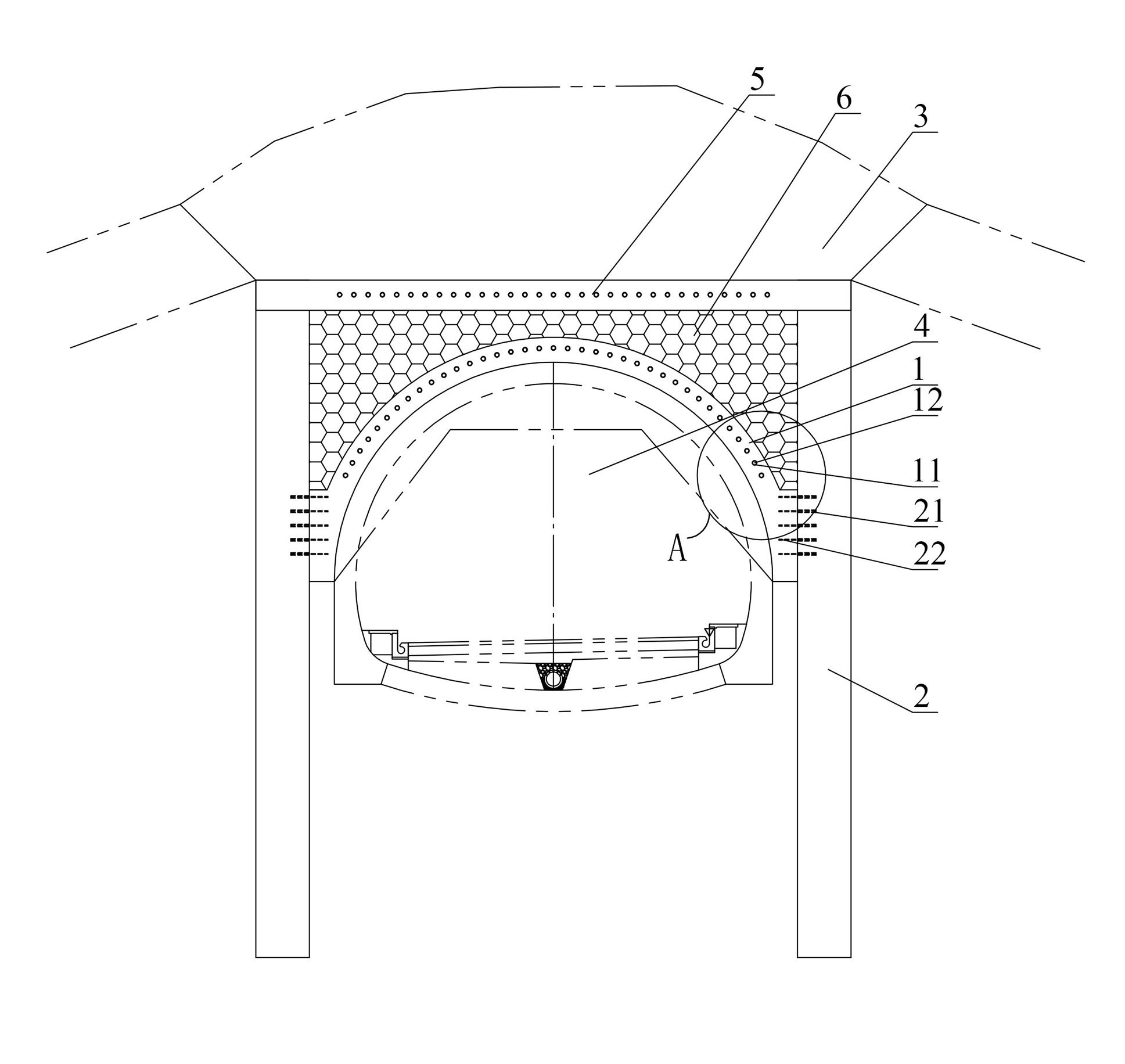

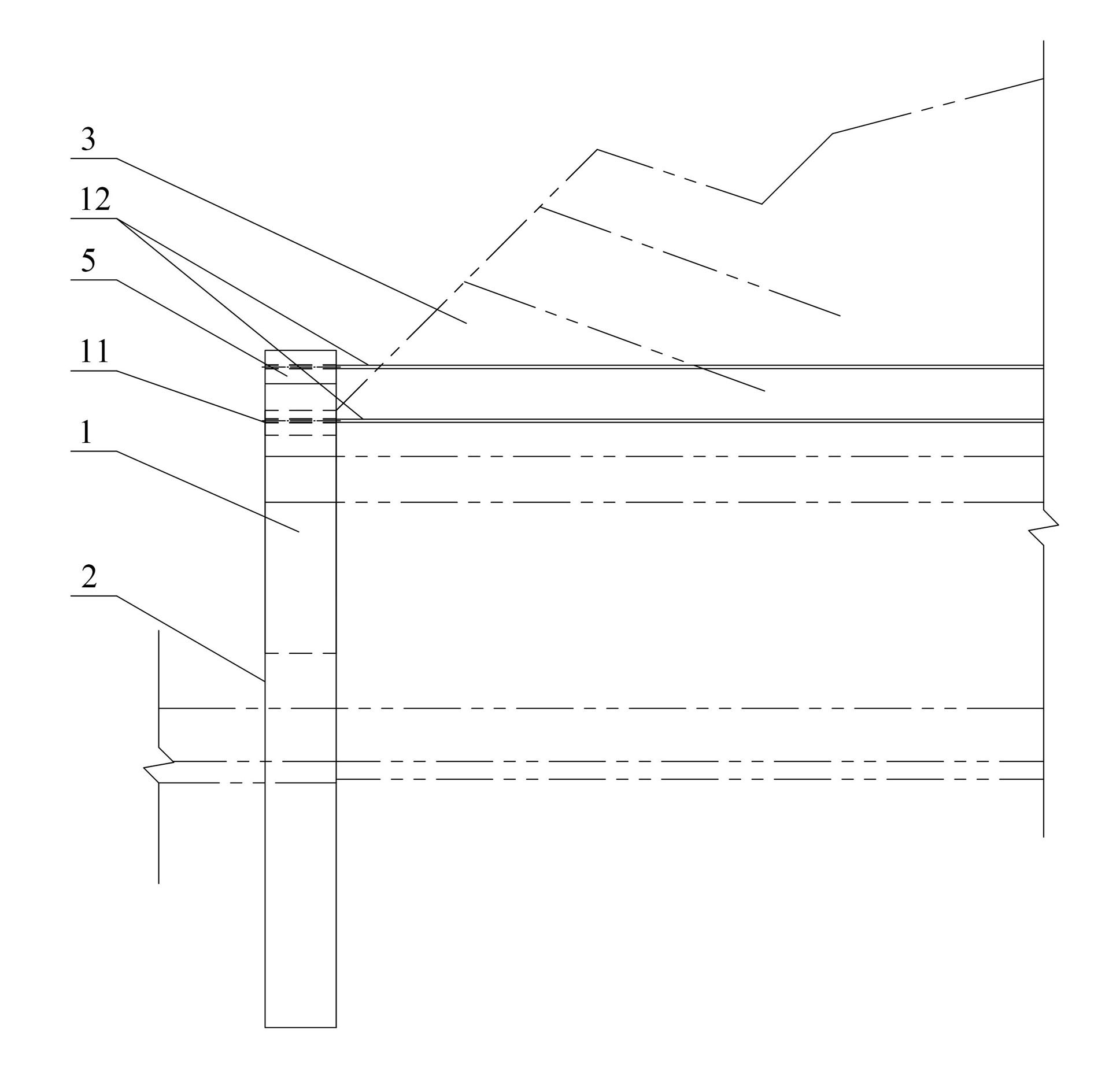

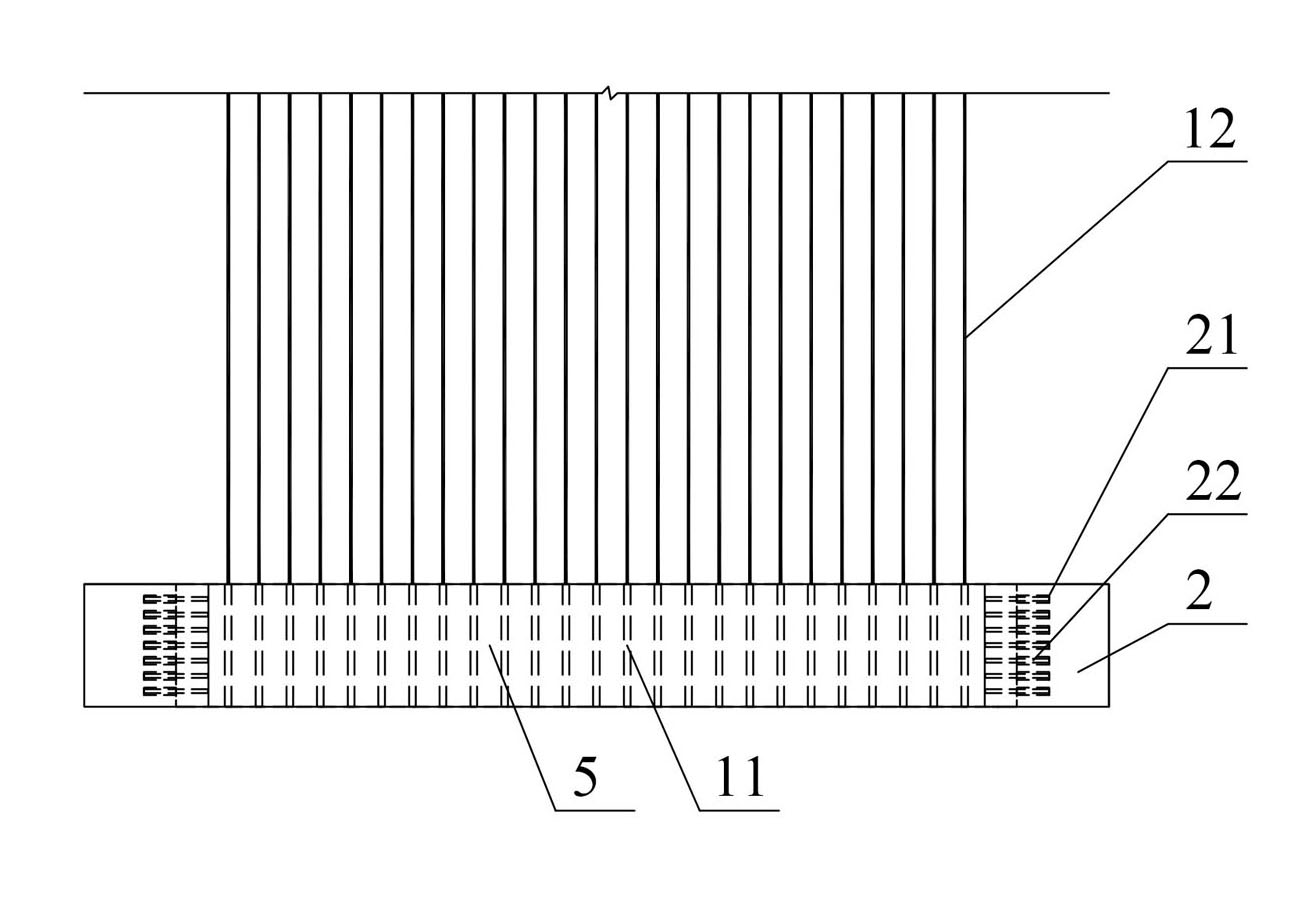

[0025] Kind of like Figure 1 ~ Figure 4 The present invention is shown for the portal type composite pipe shed arch structure of the tunnel portal. The portal type composite pipe shed arch structure includes the pipe shed arch 1 at the top of the tunnel portal and pre-reinforced piles 2 located on both sides of the tunnel portal. , The pipe shed arch 1 is supported by pre-reinforced piles 2, and the two ends of the pipe shed arch 1 are respectively connected with the pre-reinforced piles 2 on both sides. In this embodiment, the end of the pipe shed arch 1 is specifically connected to a position above the middle of the pre-reinforced pile 2. A connecting sleeve 21 is pre-embedded in the pre-reinforced pile 2, and both ends of the pipe shed arch 1 are connected to the pre-reinforced pile 2 by connecting steel bars 22 inserted into the connecting sleeve 21. A roof beam 5 is fixedly connected to the top of the pre-reinforced pile 2, and a bag of backfill 6 is filled between the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com