Space crank rocker device

A crank rocker and crank technology, applied in the field of space crank rocker devices, can solve the problems of difficult cost reduction, unsatisfactory installation accuracy, complex structure, etc., and achieve the effects of low production and processing cost, guaranteed installation accuracy, and flexible orientation adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

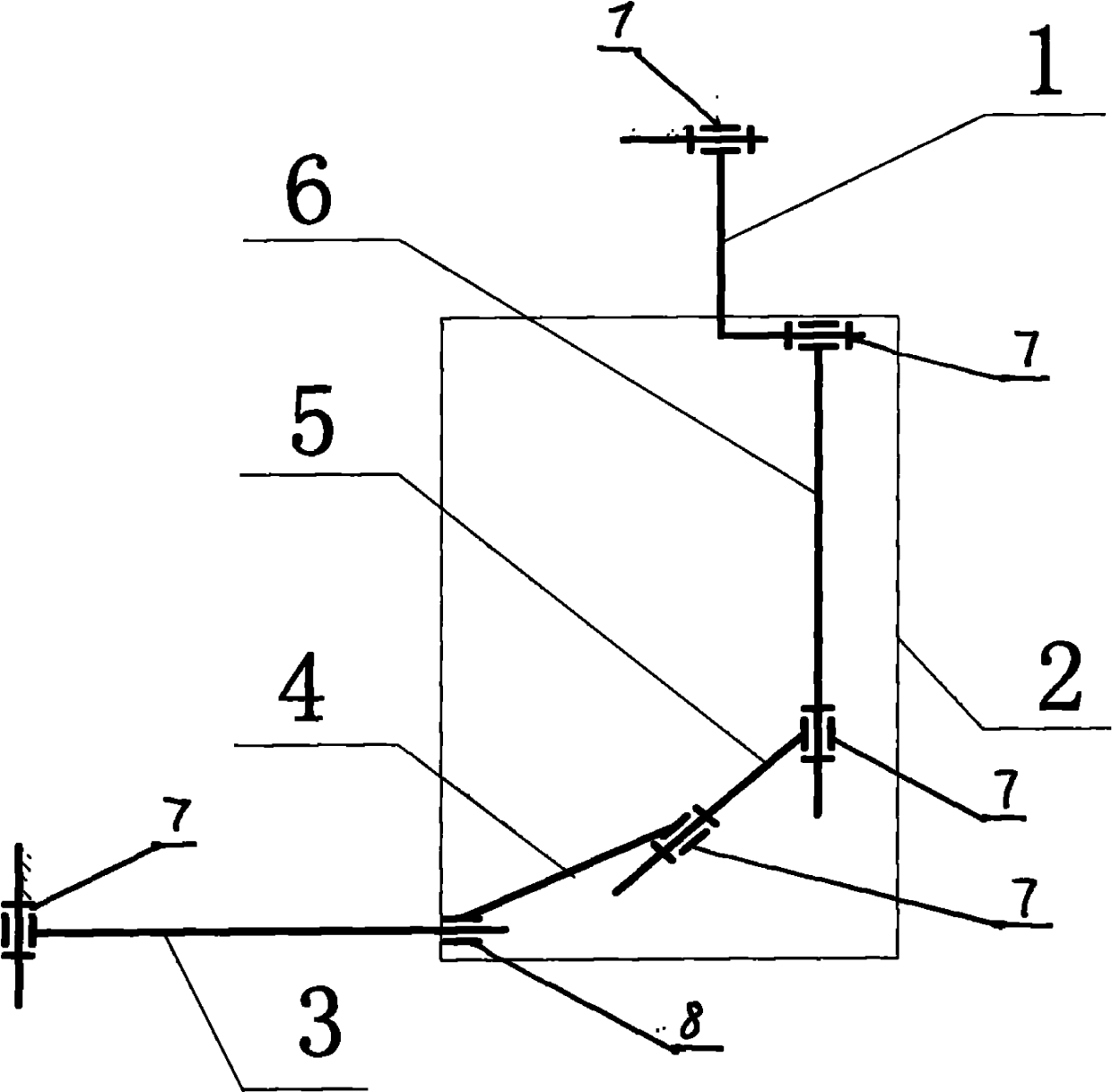

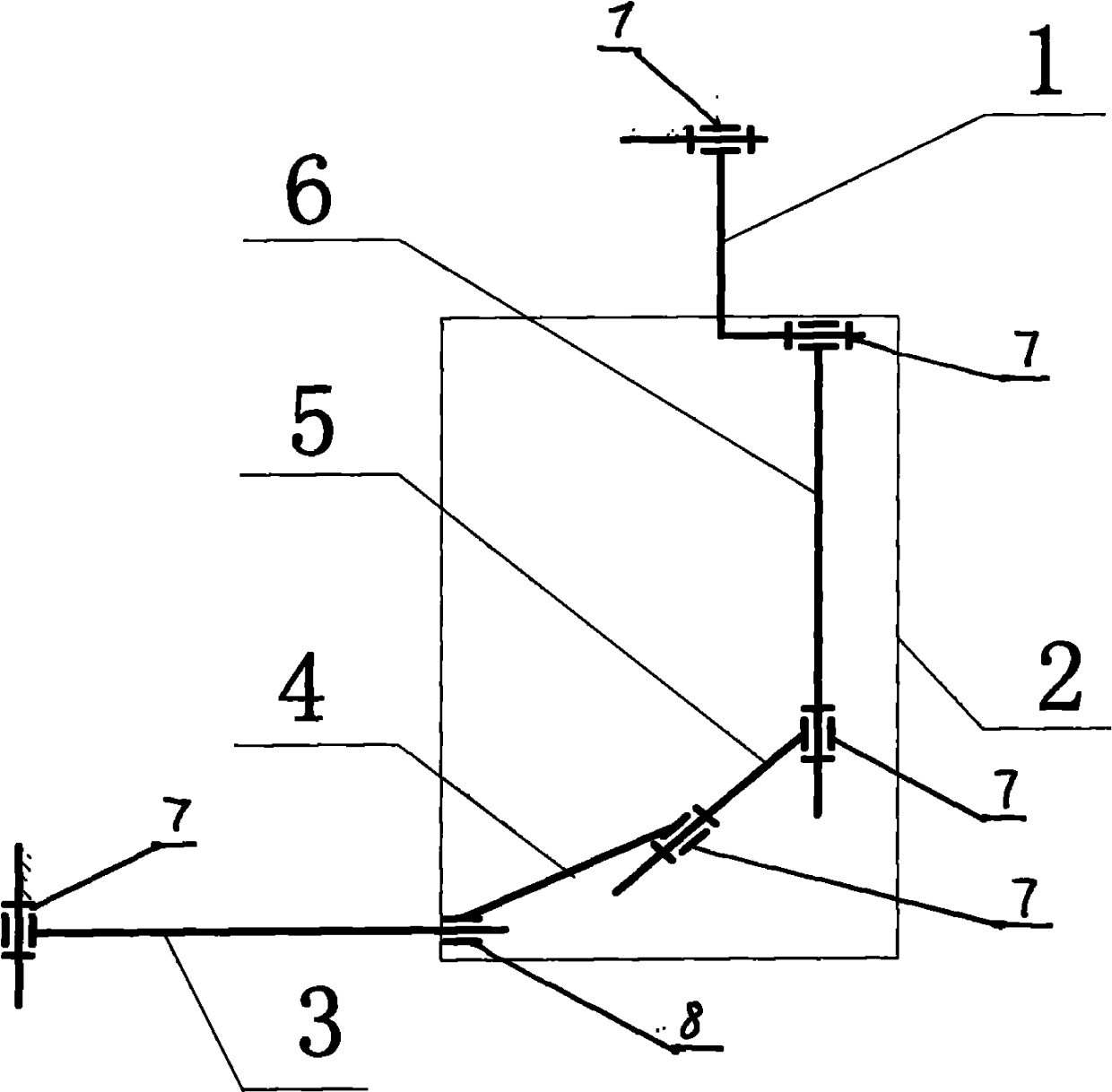

[0009] The main structure of the device in this embodiment includes a crank 1, a connecting rod 2, a rocker 3, a rotary motion pair 7, and a cylindrical surface motion pair 8. The kinematic pairs are connected; the upper member 6 forms a rotary motion pair structure with the crank 1 and the middle member 5 respectively, and the axes of the two rotary kinematic pairs intersect at an angle of 90°; the middle member 5 is connected to the lower member 6 and the upper member 4 respectively. A rotary kinematic pair structure is formed between them, and the axes of the two rotary kinematic pairs intersect to form an angle of 90°; a rotary kinematic pair structure is formed between the upper member 4 and the middle member 5, and a cylindrical kinematic pair structure is formed between the rocker 3, and the two The axes of kinematic pairs 7 and 8 intersect to form an angle of 90°; according to the arrangement of kinematic pairs, this device is a RRRRCR space crank-rocker device, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com