High-accuracy airplane wheel pre-rotating mechanism for drop test of airplane landing gear

An aircraft landing gear, high-precision technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of high requirements on the orientation and arrangement of other components in the test, difficult to accurately control the rotation speed of the wheels and tires, affecting the accuracy of the test results, etc., and achieves a simple structure. , The effect of low equipment cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

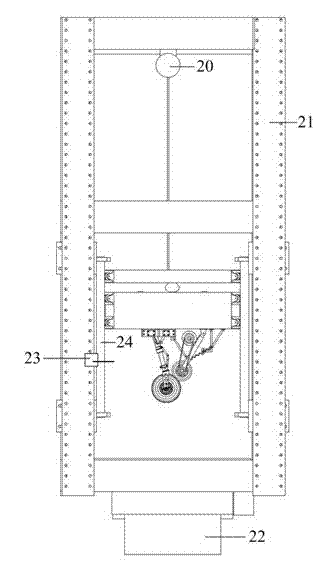

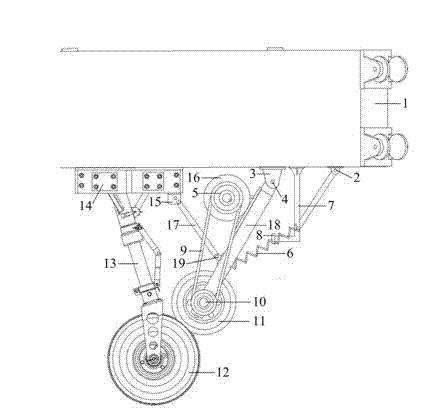

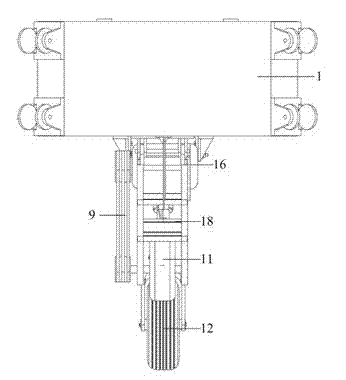

[0014] The invention is a high-precision wheel pre-rotation mechanism for aircraft landing gear drop test, which includes a hanging basket 1, a support 2, a base 3, a pin 4, a motor pulley 5, a spring 6, a positioning bracket 7, a magnet 8, and a V-shaped Belt 9, friction wheel belt pulley 10, friction wheel 11, machine wheel 12, landing gear 13, landing gear clamp 14, fixed plate 15, motor 16, connecting strip 17, pendulum frame 18, electromagnetic lock 19, lifting mechanism 20, test Stand 21, impact platform 22, travel switch 23, slideway 24. Wherein the base, the positioning bracket and the support are respectively installed on the bottom plate of the hanging basket, and a magnet is installed at the end of the positioning bracket. The pendulum is connected to the base through pins, and the pendulum can move freely around the pins. During the test, butter is applied to the pins to reduce friction. The motor and the friction wheel are installed on the swing frame, the fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com