Zigbee protocol based proportion integration differentiation (PID) parameter tuning controller

A technology of parameter setting and controller, applied in the direction of program control, computer control, general control system, etc., can solve the problems of large cables and labor, consumption, and more time, so as to reduce workload, facilitate use, and reduce measurement errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

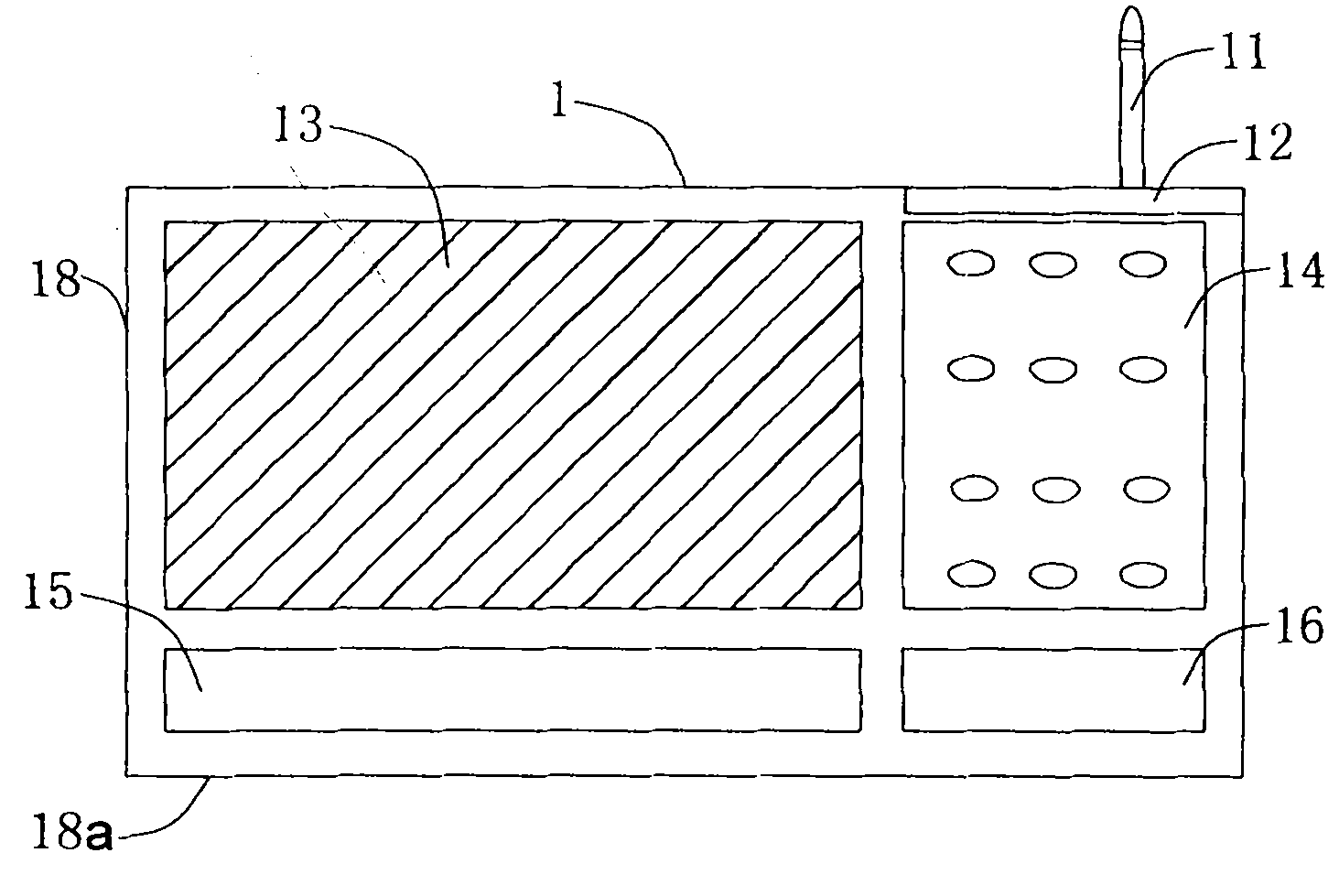

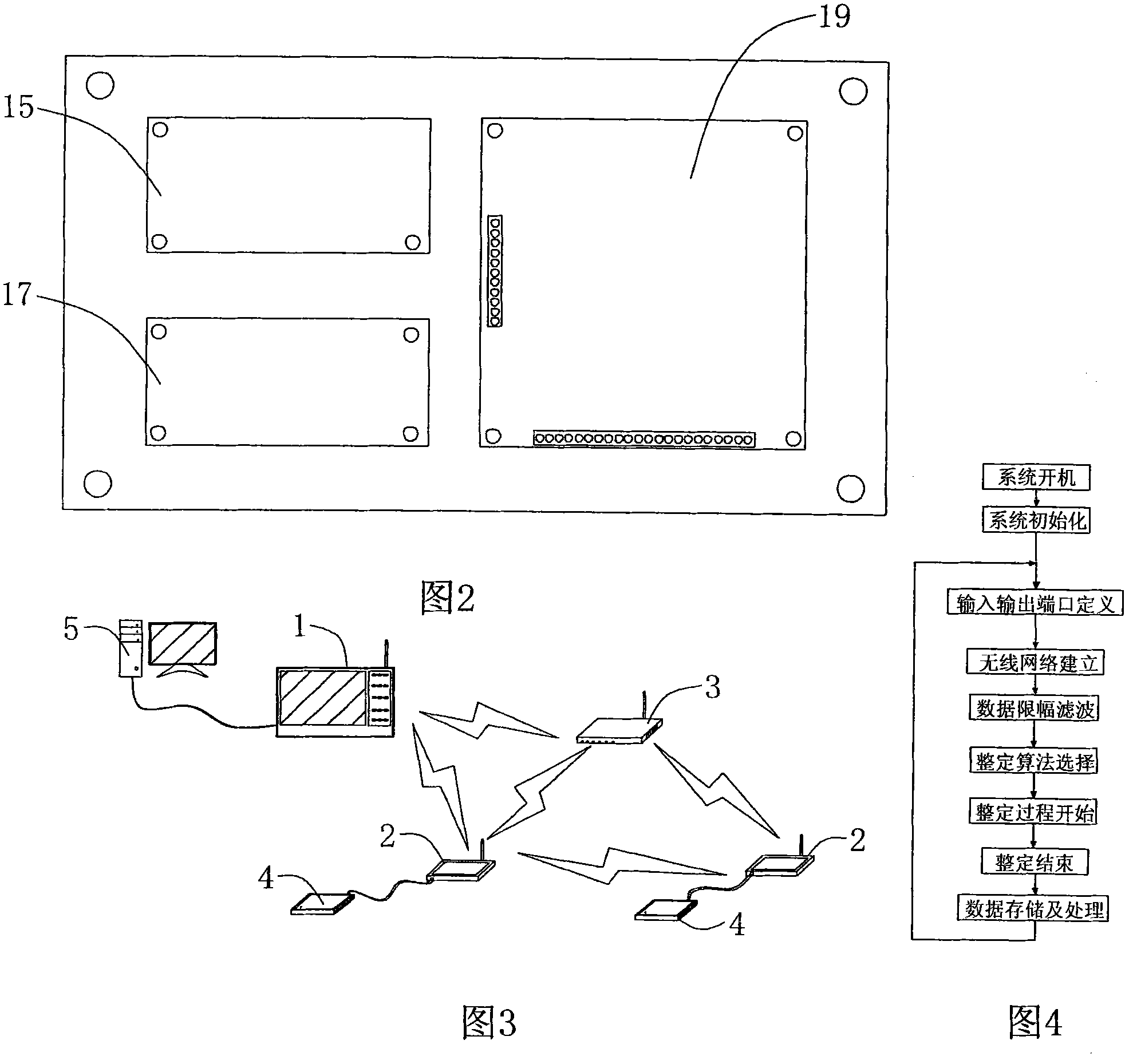

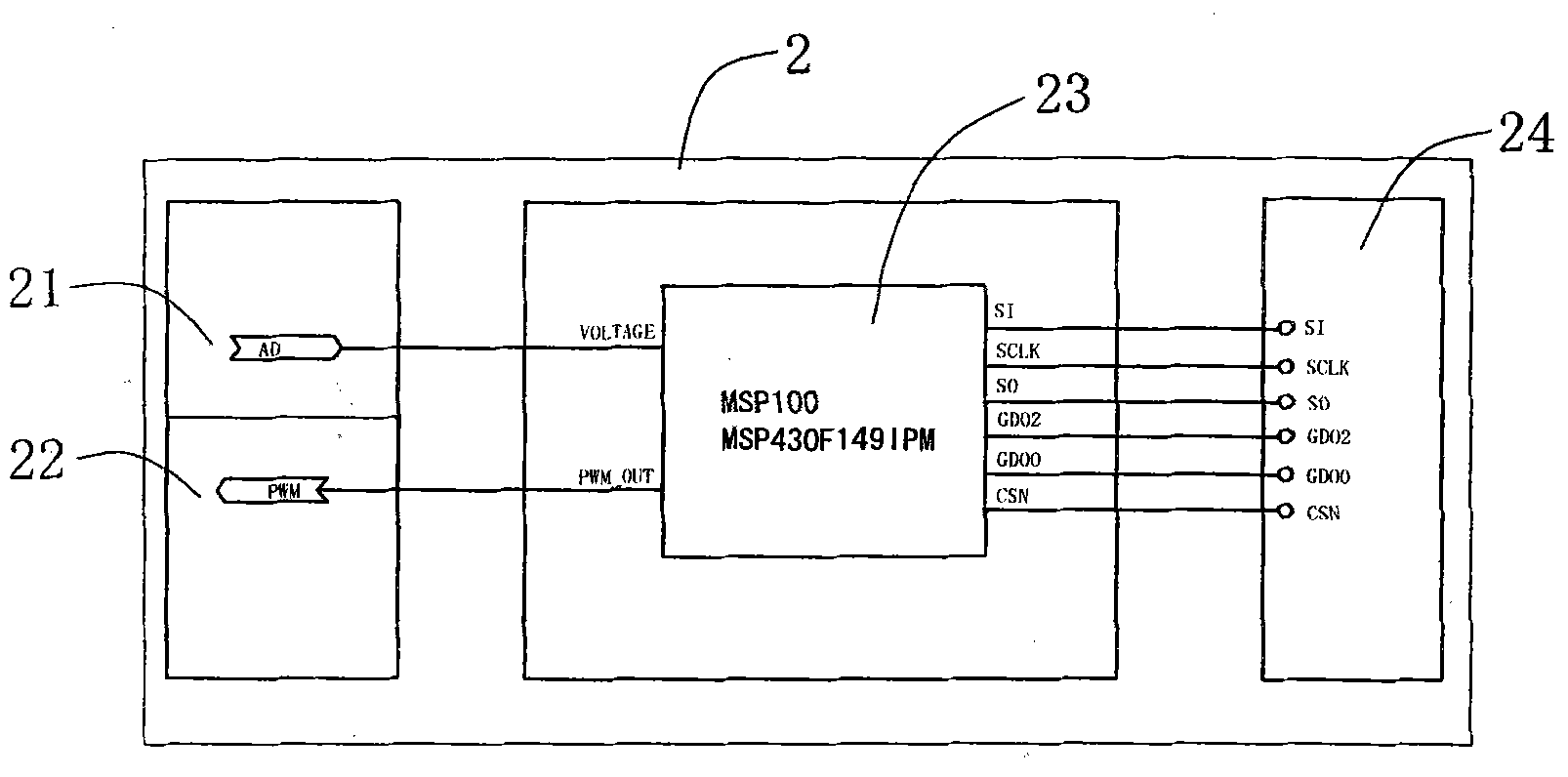

[0032] A PID parameter tuning controller based on the Zigbee protocol in this embodiment includes a PID parameter tuning controller host 1 and at least one wireless input and output node 2 for connecting to a field testing device 4 . PID parameter tuning controller host 1 includes a housing 18, an antenna 11 connected to the housing, a wireless receiving module 12 fixedly arranged in the housing 18, a main board 19 and a power supply module 15; the wireless input and output node 2 includes an input module 21 , an output module 22, a CPU module 23 and a radio frequency module 24, the PID parameter setting controller host 1 is connected to the wireless input and output node 2 through a wireless signal based on the Zigbee protocol.

[0033]The casing 18 of the PID parameter setting controller host 1 is equipped with a liquid crystal display 13 and a keyboard 14 , and the main board 19 and the power supply module 15 are fixedly matched with the bottom plate 18 a of the casing 18 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com